Micro-fluidic chip and application thereof

A microfluidic chip and microvalve technology, applied in laboratory containers, enzymology/microbiology devices, microbial measurement/inspection, etc., can solve problems such as experiment failure, amplification pollution, cell loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

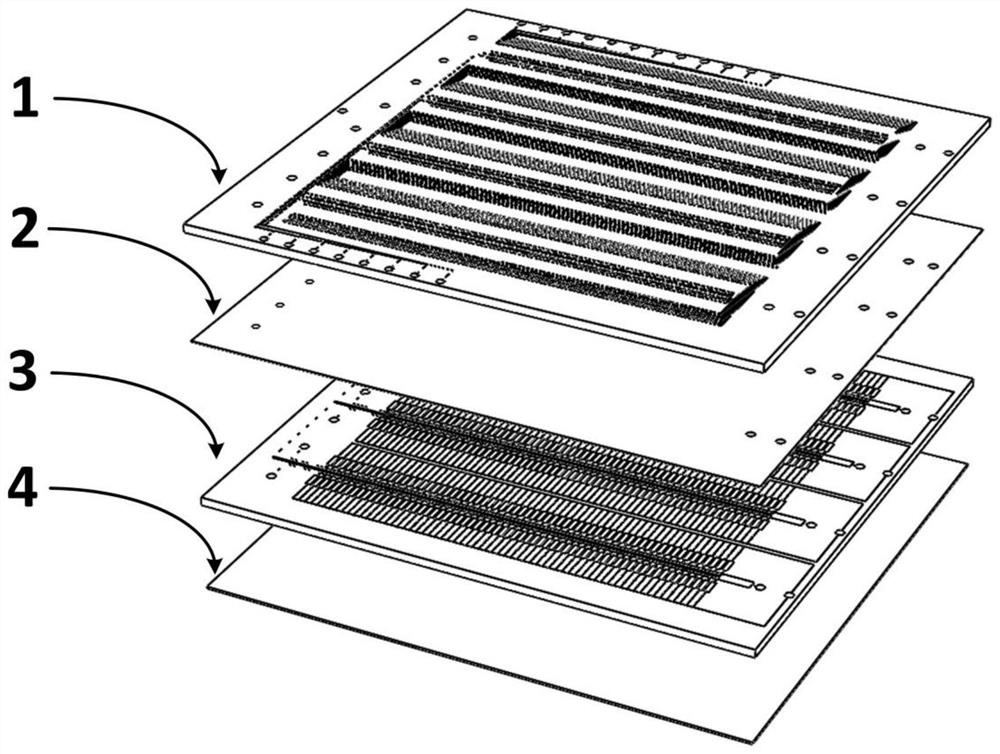

[0073] This embodiment provides a microfluidic chip, which is composed of a four-layer structure stacked together and sealed to each other. The four-layer structure is respectively a microvalve control layer 1, a microvalve film layer 2, The cell treatment layer 3 and the base layer 4 (made of glass); the microvalve control layer 1, the cell treatment layer 3 and the base layer 4 are transparent structures. The microvalve control layer 1, the microvalve film layer 2, and the cell treatment layer 3 are all made of PDMS material, and oxygen plasma is used to assist bonding. In other implementation methods, the microvalve control layer, the microvalve film layer, and the cell treatment layer can be Layer material to choose the appropriate sealing method.

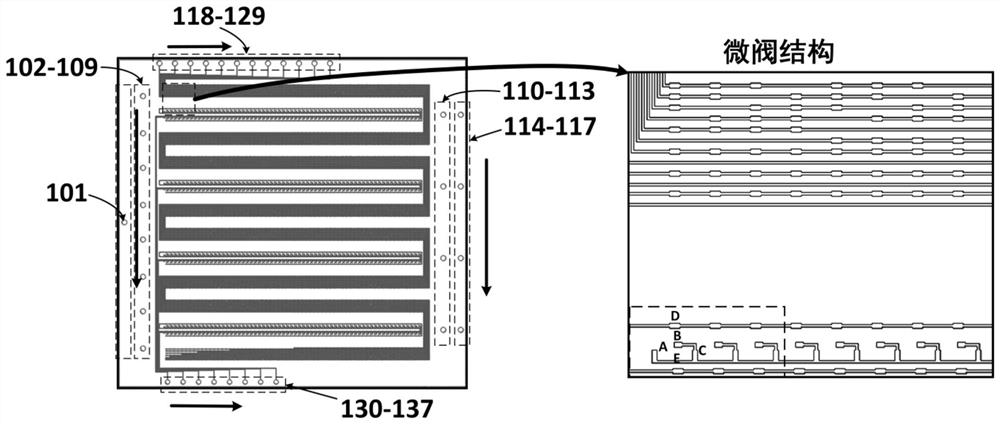

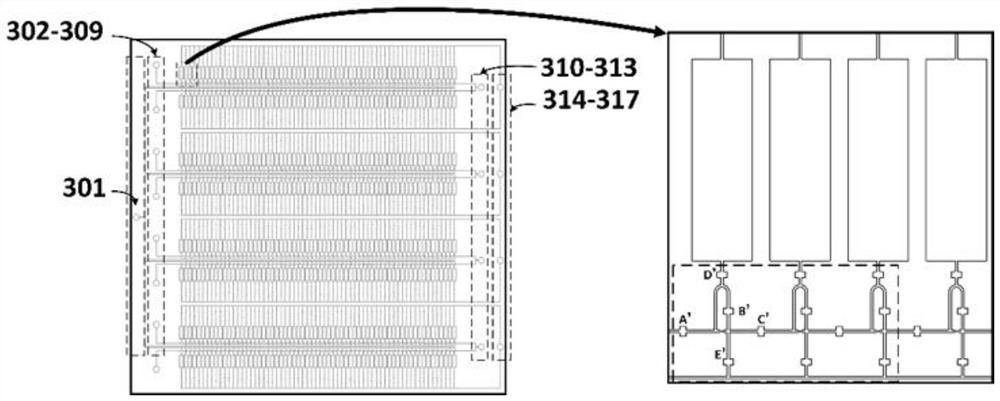

[0074] For a schematic diagram of the expansion of each layer of the microfluidic chip, see figure 1 . The schematic diagram of the top view of the microvalve control layer is shown in figure 2 In the left figure in the fig...

Embodiment 2

[0121] This example provides an application method for screening hybridoma cells and antibody gene amplification using the above-mentioned microfluidic chip. Specifically, the specific application method is described as follows by taking hybridoma cells targeting CD45 protein as an example:

[0122] All reagents are prepared in nuclease-free water during operation, and consumables are nuclease-free.

[0123] All the experimental steps are carried out in the cell room in a sterile environment, the consumables and instruments are sterilized in advance, and the reagents are all sterile.

[0124] 1. To pretreat the microfluidic chip, inject 75% ethanol into the microfluidic chip from the liquid injection port for 5 minutes to sterilize and infiltrate the surface of the flow channel to increase hydrophilicity. Inject sterile phosphate-buffered solution (PBS) to wash the ethanol in the channel. Close each chamber and enter the gene amplification chamber control microvalve D on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com