Preparation method of anhydrous scandium chloride molten salt

A technology of hydrated scandium chloride and scandium chloride, applied in the preparation/treatment of rare earth metal compounds, rare earth metal chlorides, rare earth metal halides, etc., can solve the problems of difficult industrial production and safe production of the preparation process, and achieve industrial applicability Strong, easy to store, low hydrolysis rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

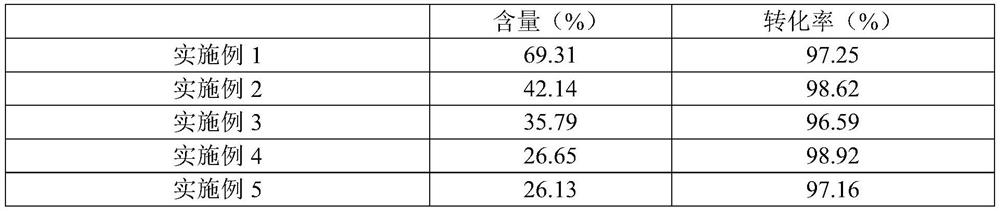

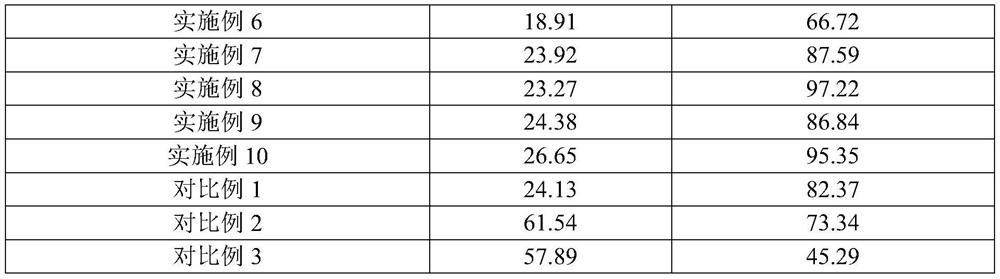

Examples

preparation example Construction

[0021] As analyzed in the background art of the present application, the preparation process of anhydrous scandium chloride in the prior art is difficult for industrial safety production due to complicated equipment or high risk of toxic gas leakage. In order to solve this problem, the present application provides a preparation method of anhydrous scandium chloride molten salt, the preparation method includes: step S1, using concentrated hydrochloric acid to dissolve scandium oxide to prepare a scandium chloride solution; step S2, mixing NaCl, KCl and NH 4 The mixed solution of Cl is mixed with the scandium chloride solution to obtain a scandium chloride molten salt solution; in step S3, the scandium chloride molten salt solution is first heated to evaporate HCl and more than 90% of free water to obtain a water-containing scandium chloride molten salt solution. Salt, aqueous scandium chloride molten salt containing NH 4 Cl, free water and crystal water; Step S4, the second he...

Embodiment 1

[0036] A scandium chloride solution was prepared by dissolving 10 g of scandium oxide with a purity of 99.0% by using 50 mL of hydrochloric acid with a concentration of 30% at a heating temperature of 90°C. Configure NaCl, KCl and NH 4 Cl mixed solution, then the scandium chloride solution was mixed with the chloride mixed solution, in which Sc 2 O 3 , (KCl+NaCl) and NH 4 The mass ratio of Cl is 1:1:3. After stirring, the residue is filtered off to obtain a mixed molten salt solution of scandium chloride, and KCl and NaCl are added in equimolar. The mixed molten salt solution of scandium chloride prepared above is heated to 120 ° C, and excess HCl and about 90% of free water are evaporated to obtain a hydrous scandium chloride molten salt, and the hydrous scandium chloride molten salt contains NH 4 Cl, free water and crystal water. The water-containing scandium chloride molten salt is put into an oven, heated to 110° C., maintained for 4 hours, and dried to completely remo...

Embodiment 2

[0038] The scandium chloride solution was prepared by dissolving 15 g of scandium oxide with a purity of 99.5% by using 105 mL of hydrochloric acid with a concentration of 35% at a heating temperature of 80°C. Configure NaCl, KCl and NH 4 Cl mixed solution, then the scandium chloride solution was mixed with the chloride mixed solution, in which Sc 2 O 3 , (KCl+NaCl) and NH 4 The mass ratio of Cl is 1:3:6. After stirring, the residue is filtered off to obtain a molten salt solution of scandium chloride, and KCl and NaCl are added in equimolar. The scandium chloride molten salt solution prepared above is heated to 150 ° C, and excess HCl and about 92% of free water are evaporated to obtain a hydrous scandium chloride molten salt, and the hydrous scandium chloride molten salt contains NH 4 Cl, free water and crystal water. The aqueous scandium chloride molten salt is put into an oven, the temperature is raised to 90 ° C, the temperature is maintained for 6 hours, and the rema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com