A kind of preparation method and application of high water-reducing polycarboxylate superplasticizer

A technology of superplasticizer and polycarboxylic acid, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of self-polymerization of unsaturated ester monomers and the problem of insufficient increase in the proportion of carboxyl groups. Low cost, reduced dosage, and reduced viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

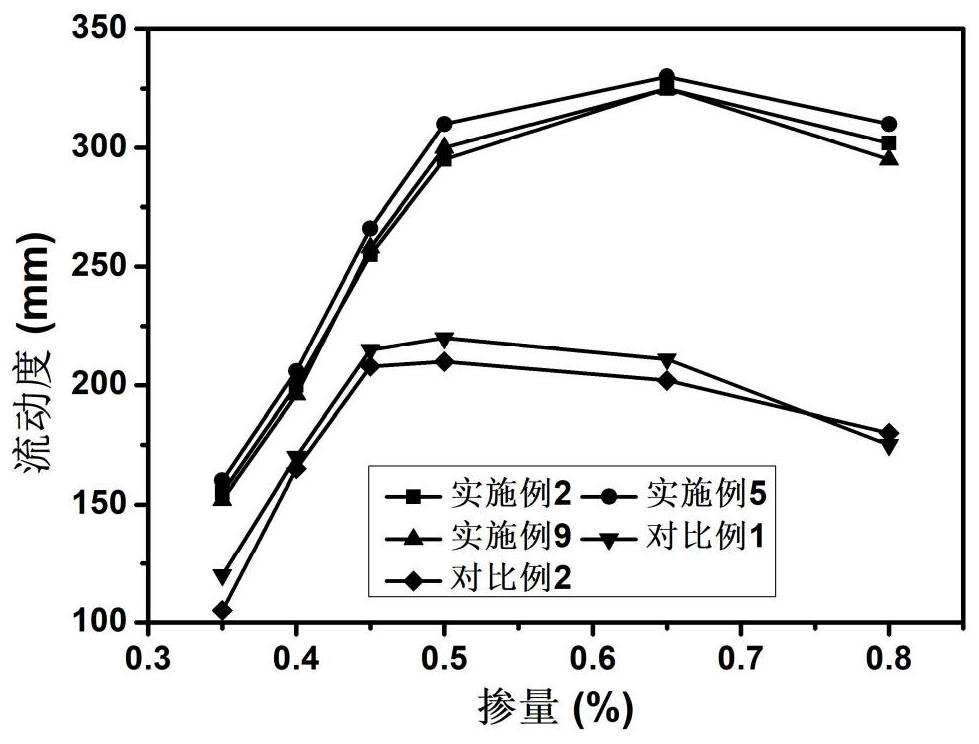

Examples

Embodiment 1

[0051] The preparation steps of the high water-reducing type polycarboxylic acid superplasticizer are as follows:

[0052] Synthesis of side chain macromonomer C-1: add 30wt% hydrogen peroxide (0.028mol, 3.18g) and solvent water 50g to a four-necked flask equipped with a stirrer and a thermometer, stir evenly, and control the temperature to be 10°C, At this temperature, dropwise added acrylic acid (1mol, 72g), hydroxyethyl acrylate (1mol, 116g), E-1 (0.2mol, 32.4g), L-ascorbic acid (0.007mol, 1.23g) and water 138g The mixed solution of C-1 was added dropwise for 2h. After the dropwise addition, the temperature was kept for 1h to obtain the aqueous solution of C-1. GPC measured M w is 1020;

[0053] Synthesis of high water-reducing type polycarboxylic acid superplasticizer: to the solution of C-1 synthesized above, add isopentenyl polyoxyethylene ether (M w 1000, 0.4mol, 400g) and 400g of water, stir evenly, and control the temperature to 50°C. The mixed solution composed of...

Embodiment 2

[0055] The preparation steps of the high water-reducing type polycarboxylic acid superplasticizer are as follows:

[0056] Synthesis of side chain macromonomer C-2: add 30wt% hydrogen peroxide (0.0645mol, 7.31g) and solvent water 50g to the four-necked flask equipped with a stirrer and a thermometer, stir evenly, and control the temperature to be 20°C, At this temperature, a mixture of hydroxyethyl acrylate (1 mol, 116 g), acrylic acid (1 mol, 72 g), E-2 (0.15 mol, 24 g), L-ascorbic acid (0.0215 mol, 3.78 g) and 160 g of water was added dropwise. The mixed solution was added dropwise for 1h. After the dropwise addition, the temperature was kept for 1h to obtain an aqueous solution of C-1. GPC measured M w is 1250;

[0057] Synthesis of high water-reducing type polycarboxylate superplasticizer: add vinyl polyoxyethylene ether (M w 2000, 0.5mol, 1000g) and 500g of water, stir evenly, and control the temperature to 40°C. -the mixed solution that ascorbic acid (0.0215mol, 3.78g...

Embodiment 3

[0059] The preparation steps of the high water-reducing type polycarboxylic acid superplasticizer are as follows:

[0060] Synthesis of side chain macromonomer C-3: add 30wt% hydrogen peroxide (0.135mol, 15.3g) and solvent water 50g to a four-necked flask equipped with a stirrer and a thermometer, stir evenly, and control the temperature to be 30°C, At this temperature, hydroxyethyl acrylate (1 mol, 116 g), methacrylic acid (1 mol, 86 g), E-3 (0.135 mol, 25.7 g), L-ascorbic acid (0.00846 mol, 1.49 g) and water were added dropwise The mixed solution composed of 160g was added dropwise for 1h, and kept for 1h after the dropwise addition to obtain an aqueous solution of C-3. GPC measured M wis 1510;

[0061] Synthesis of high water-reducing type polycarboxylic acid superplasticizer: add methallyl polyoxyethylene ether (M w 3000, 0.65mol, 1950g) and water 1000g, stir evenly, control the temperature to 20°C, at this temperature, dropwise add fumaric acid (2.6mol, 301.6g), mercapt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com