Crack flexible strain sensor based on graphene-gold composite film and preparation method

A technology of strain sensor and composite thin film, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement device, etc., can solve the problems of variable height sensitive response, wide linear sensing range, and insignificant sensing gain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

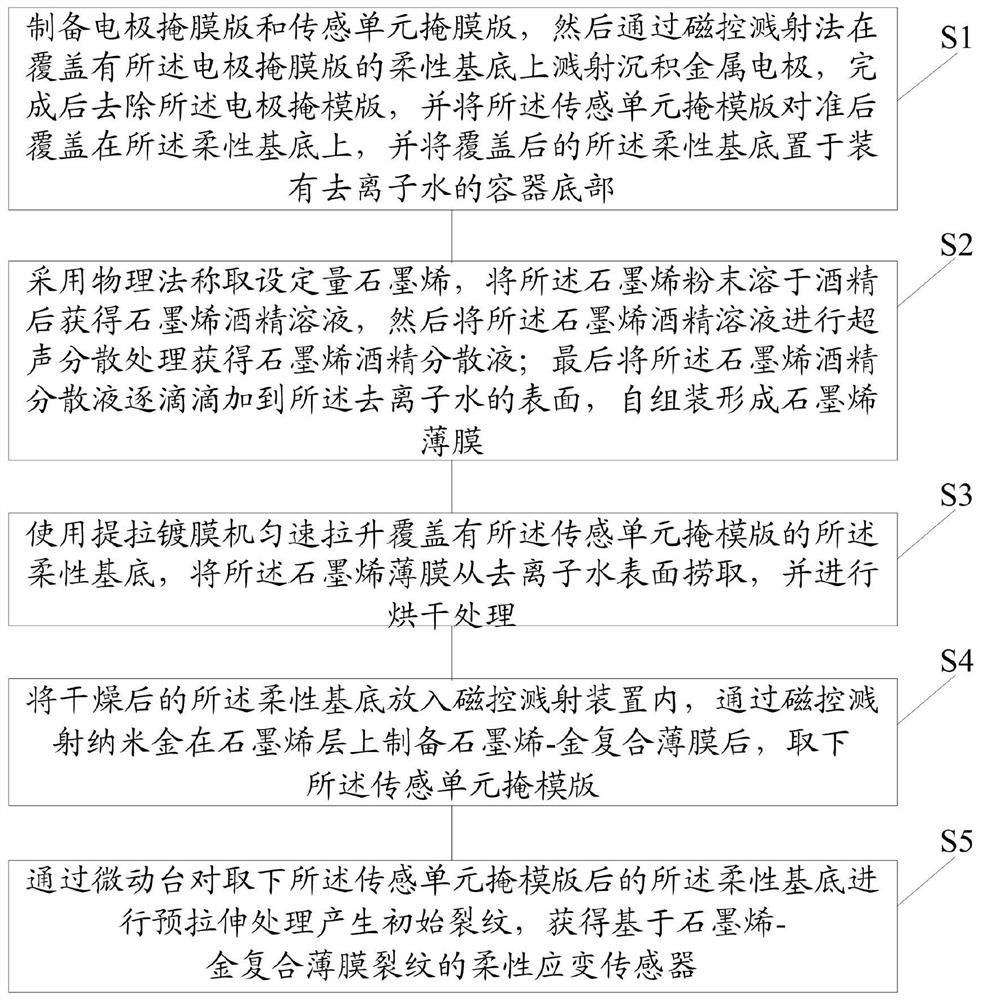

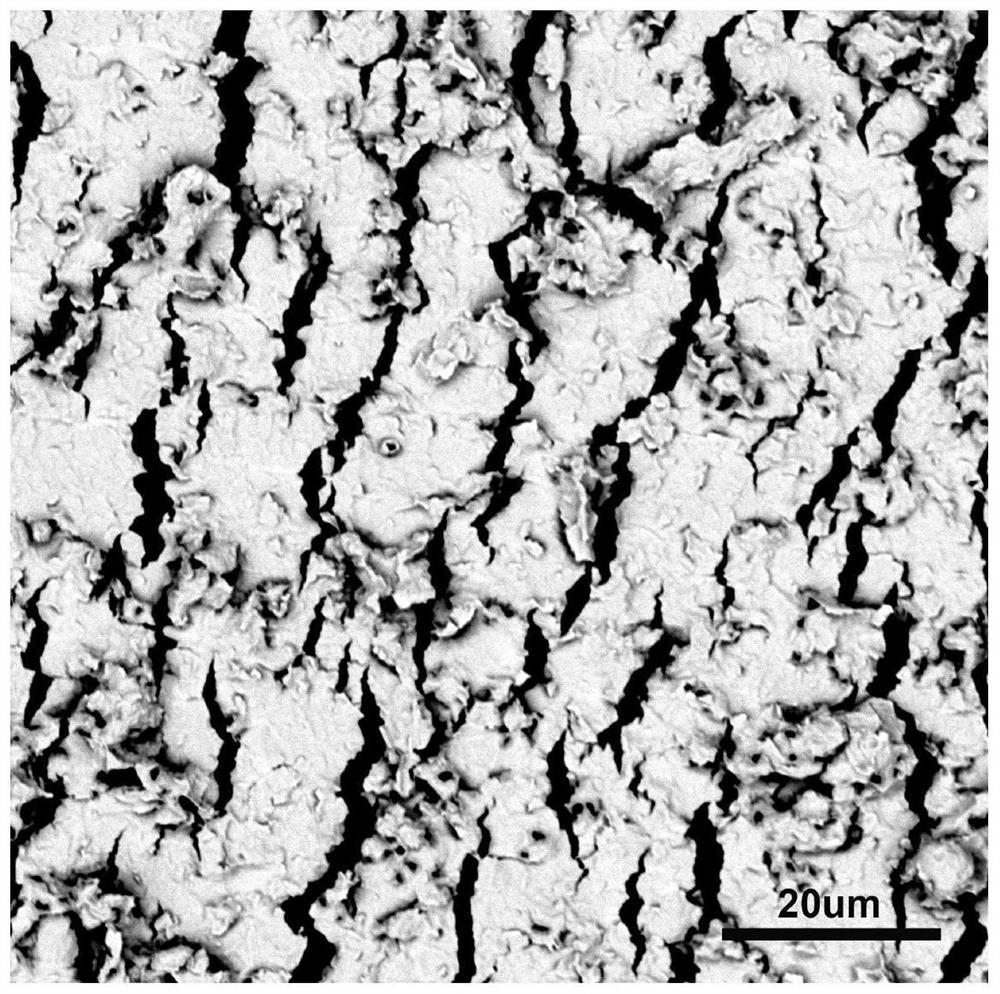

[0041] In this embodiment, the process flow of the preparation method of the flexible strain sensor based on the graphene-gold composite film crack is as follows figure 1 , which includes the following steps:

[0042] Step S1: Prepare the electrode mask and the sensing unit mask, and then sputter-deposit metal electrodes on the flexible substrate covered with the electrode mask by magnetron sputtering, and remove the electrode mask after completion , and align the mask plate of the sensing unit and cover it on the flexible substrate, and place the covered flexible substrate on the bottom of the container filled with deionized water; in this embodiment, laser cutting can be used The electrode mask and the sensing unit mask are prepared on the metal mask by method or chemical etching. The line width of the electrode pattern of the electrode mask is 1mm, and the size of the sensing unit pattern of the sensing unit mask is 5mm×5mm.

[0043]Step S2: Weighing 30 mg of graphene by ...

Embodiment 2

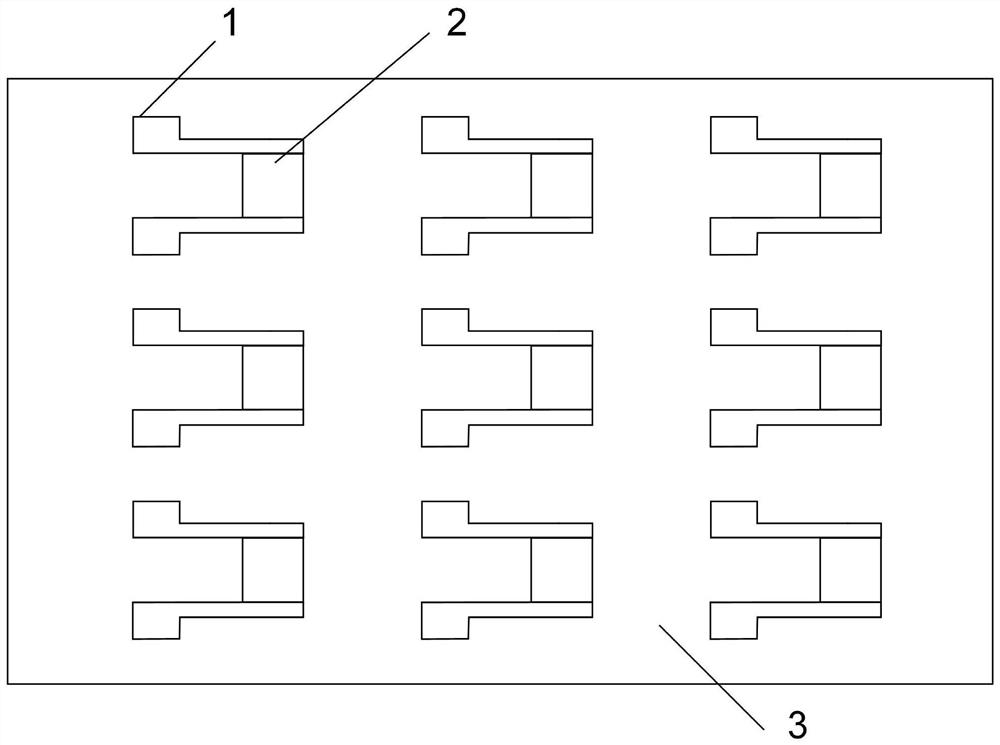

[0049] Repeat the preparation process method in embodiment 1 to obtain as figure 2 The flexible strain sensor shown. Fix the prepared flexible strain sensor on the micro-motion stage through the clamp, apply 1% to 15% cyclic tensile strain to the flexible strain sensor through the micro-motion stage, and connect the metal electrode of the flexible strain sensor to the digital source meter , Measure the change of its resistance value and store the data with computer software. The obtained resistance change curve caused by the strain in the time domain, such as Figure 4 shown. This set of signal curves shows that the flexible strain sensor based on the graphene-gold composite film crack has high sensitivity (GF>130) and repeatable measurement capability. Further processing the obtained strain-resistance curve, such as Figure 5 shown. The curve shows that the flexible strain sensor based on the graphene-gold composite film crack maintains good linearity (R 2 ~0.9971).

Embodiment 3

[0051] Repeat the preparation process method in embodiment 1 to obtain as figure 2 The flexible strain sensor shown. The prepared flexible strain sensor is fixed on the micro-motion stage through the clamp, and the strain sensor is cyclically applied and released 1% of the tensile strain by the micro-motion stage for 1500 times. At the same time, the metal electrode of the flexible strain sensor is connected to the digital source meter. Measure the change of its resistance value and store the data with computer software. The resulting cyclic strain-resistance curve, such as Image 6 shown. This curve demonstrates the good stability of the flexible strain sensor based on cracks in the graphene-gold composite film under cyclic strain conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com