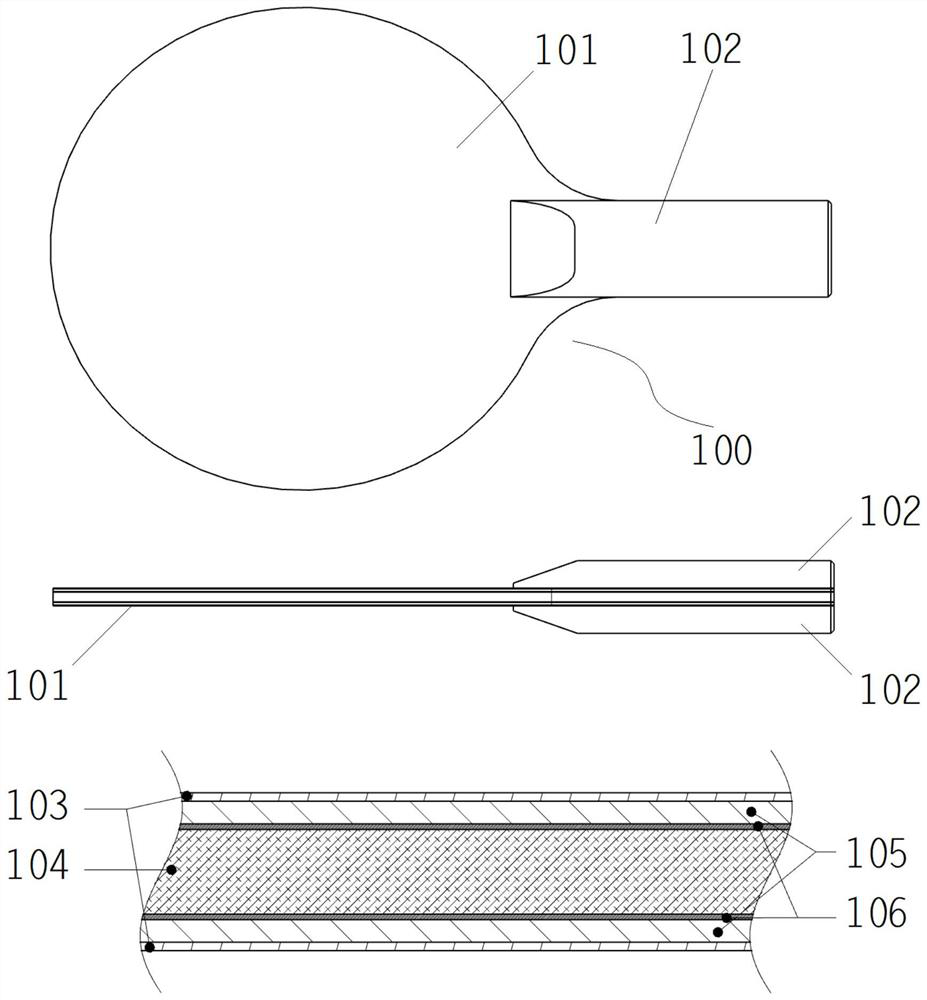

Table tennis bat bottom plate containing fiber interlayer with surface microcosmic coating and manufacturing method thereof

A table tennis racket and fiber layer technology, used in rackets, sports accessories, etc., can solve the problems of high hardness and elasticity, and achieve the goal of improving the toughness of the bottom plate, improving the uniformity of force, and increasing the optimal hitting area of the bottom plate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

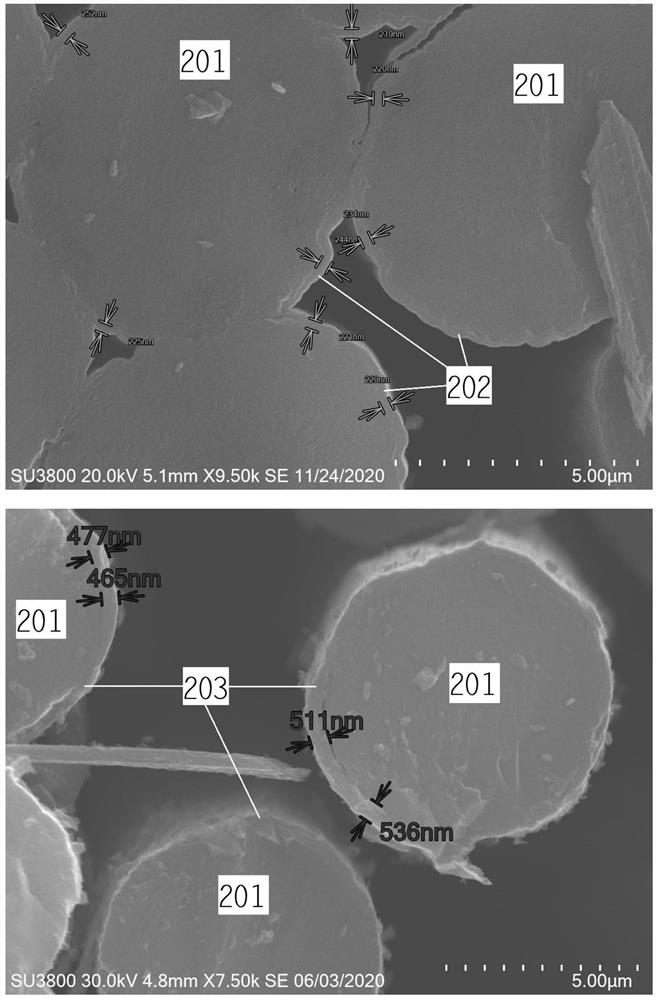

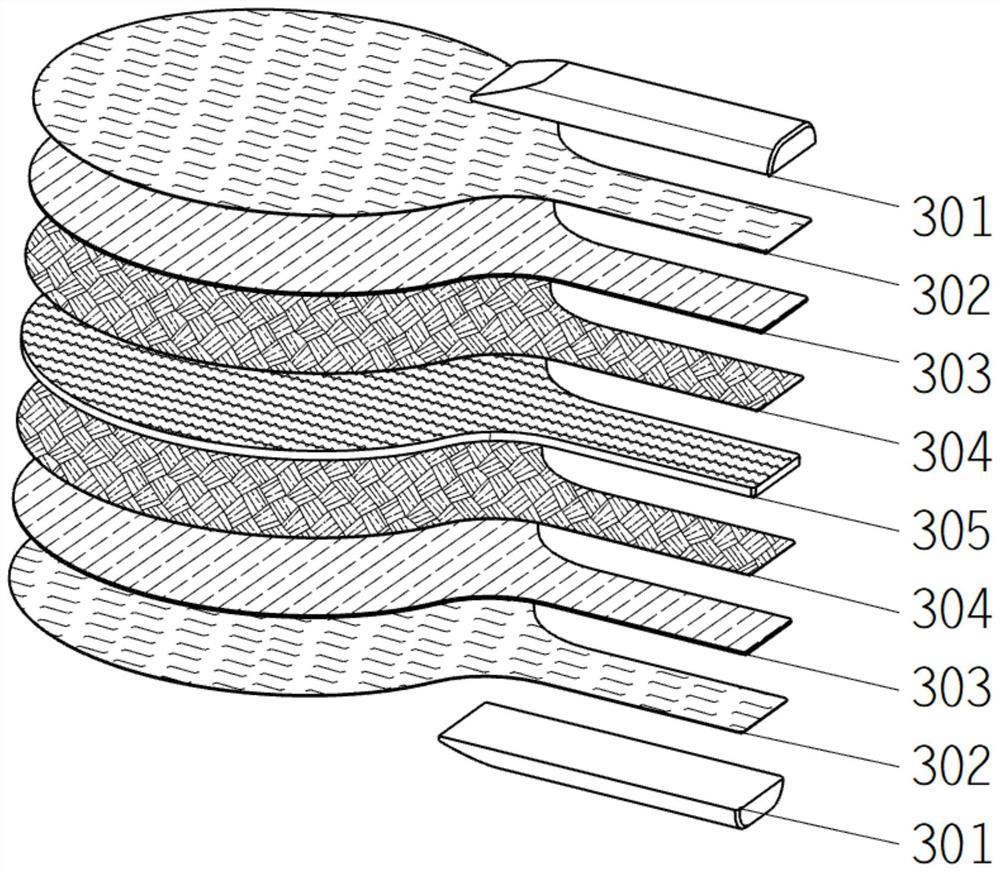

[0035] In embodiment 1, core material adopts the paulownia wood that thickness is 3.5mm, and strength material adopts the Ayousi wood that thickness is 0.8mm, and surface material adopts the Ketuo wood that thickness is 0.5mm; The two-dimensional plain weave cloth made of fiber bundles is used as the fiber interlayer, and the surface of each fiber in the fiber interlayer is covered with a pyrolytic carbon layer with a thickness of 220-250 nanometers, and the thickness of a single layer of fiber interlayer is 0.16mm. The base plate of the table tennis racket obtained in this embodiment meets the standard of the International Table Tennis Federation for the base plate of a table tennis racket used in competitions.

[0036] For microscopic coatings using pyrolytic carbon materials, the fiber layer is placed in a chemical vapor infiltration equipment, and a mixed gas of propylene, natural gas and hydrogen is introduced. The temperature of the inner cavity of the equipment is 600-11...

Embodiment 2

[0037] In embodiment 2, the core material adopts Ayousi wood with a thickness of 4mm, the strength material adopts Ayousi wood with a thickness of 0.7mm, and the face material adopts Limba wood with a thickness of 0.5mm; each bundle contains 1000 carbon fiber sheets A two-dimensional plain weave cloth woven from silk fiber bundles is used as a fiber interlayer, and the surface of each fiber in the fiber interlayer is covered with a boron nitride layer with a thickness of 500-650 nanometers, and the thickness of a single-layer fiber interlayer is 0.18 mm. The base plate of the table tennis racket obtained in this embodiment meets the standard of the International Table Tennis Federation for the base plate of a table tennis racket used in competitions.

[0038] For the microscopic coating using boron nitride material, the fiber layer is placed in the chemical vapor infiltration equipment, and the mixed gas of ammonia, boron chloride and hydrogen is introduced. The temperature of ...

Embodiment 3

[0051] Embodiment 3 and Embodiment 4 are: the strength material layer of Ayousi wood is not used, and the materials containing continuous ceramic fibers are bonded between the core material and the surface material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com