Modified sepiolite as well as preparation method and application thereof

A sepiolite and modification technology, applied in chemical instruments and methods, other chemical processes, inorganic chemistry, etc., can solve the problems of low heavy metal adsorption, high production energy consumption, complex process, etc., and achieve improved adsorption and adsorption Speed, low cost, and the effect of optimizing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

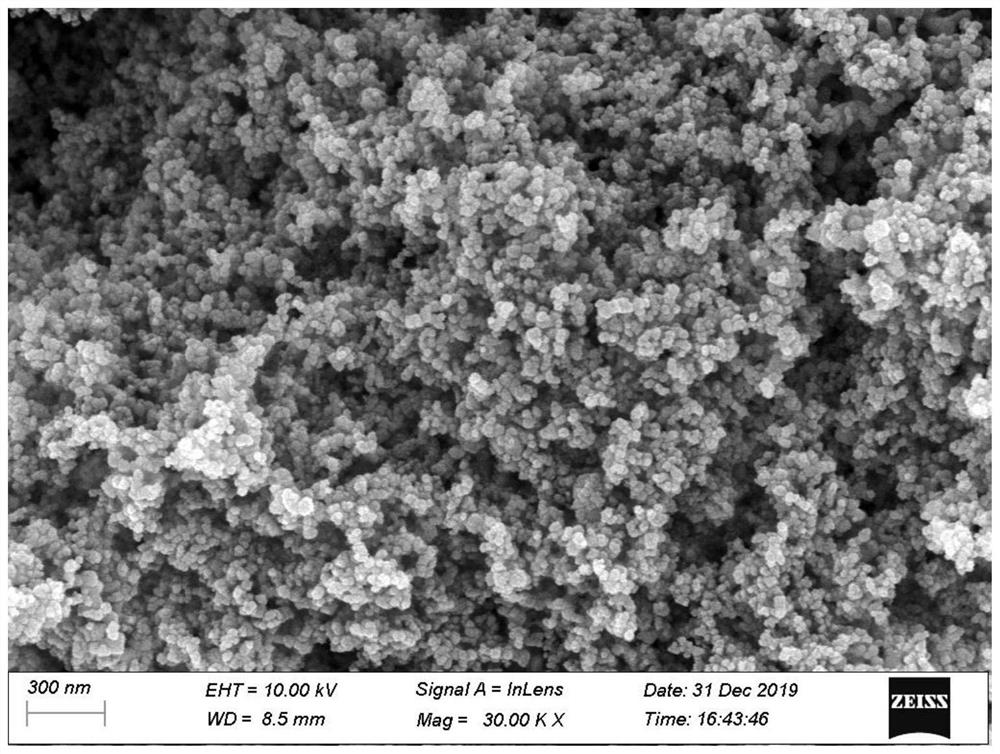

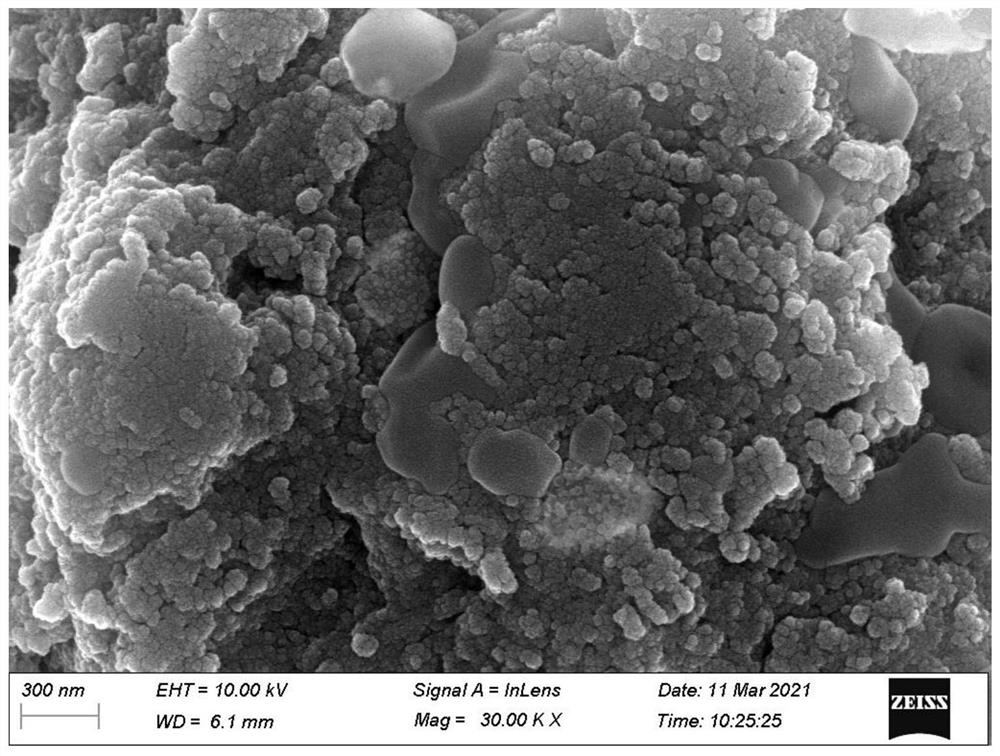

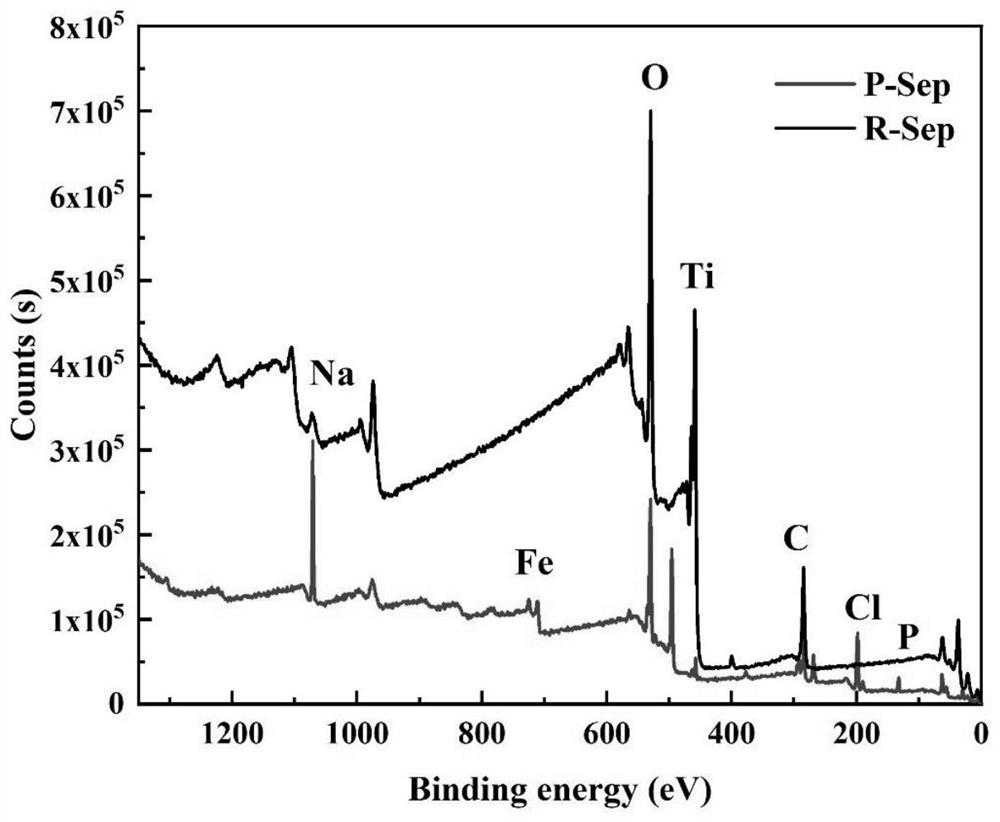

[0043] The invention provides a kind of preparation method of modified sepiolite, comprises the following steps:

[0044] (1) adding sepiolite to potassium dihydrogen phosphate solution and stirring;

[0045] (2) ferric chloride solution is added to the mixed solution of step (1) and maintained stirring;

[0046] (3) adjust the pH of the mixed solution and maintain stirring;

[0047] (4) Washing, suction filtering, drying, grinding and sieving the reacted sepiolite to obtain modified sepiolite.

[0048] Preferably, the amount of sepiolite added in step (1) is 5-15 g; more preferably, the amount of sepiolite added is 10 g.

[0049] Preferably, the concentration of potassium dihydrogen phosphate solution in step (1) is 0.7~1.0mol / L, and the addition amount of potassium dihydrogen phosphate solution is 120~150mL; more preferably, the concentration of potassium dihydrogen phosphate solution is 0.8mol / L, The amount of potassium dihydrogen phosphate solution added is 140mL.

[0...

Embodiment 1

[0067] A kind of modified sepiolite, its preparation method comprises the steps:

[0068] (1) Weigh 5g of sepiolite powder, add it to a beaker containing 120mL, 1.0mol / L potassium dihydrogen phosphate, and react at 20°C and 200r / min for 1.5h;

[0069] (2) Add 80mL, 1.8mol / L ferric chloride to the mixed solution in step (1), maintain the reaction temperature and stirring speed for 1.5h;

[0070] (3) Add dropwise 1 mol / L sodium hydroxide to the new mixed solution in step (2) to adjust its pH to 9.0, and maintain the reaction temperature and stirring speed for 3 hours.

[0071] (4) Rinse the reacted sepiolite 5 times with deionized water and place it in an oven, set the drying temperature to 50°C, and dry for 6 hours; grind the dried sepiolite and pass through a 100-mesh sieve The modified sepiolite was obtained after sieving with a net.

Embodiment 2

[0073] A kind of modified sepiolite, its preparation method comprises the steps:

[0074] (1) Weigh 15g of sepiolite powder, add it to a beaker containing 150mL, 0.7mol / L potassium dihydrogen phosphate, and react at 30°C, 400r / min for 0.5h;

[0075] (2) Add 120mL, 1.2mol / L ferric chloride to the mixed solution in step (1), maintain the reaction temperature and stirring speed for 0.5h;

[0076] (3) Add dropwise 1 mol / L sodium hydroxide to the new mixed solution in step (2) to adjust its pH to 10.0, and maintain the reaction temperature and stirring speed for 1 h.

[0077] (4) Rinse the reacted sepiolite 5 times with deionized water and place it in an oven, set the drying temperature to 80°C, and dry for 4 hours; grind the dried sepiolite and pass through a 100-mesh sieve The modified sepiolite was obtained after sieving with a net.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com