Mo-V-Te-Nb-O catalyst and preparation method and application thereof

A technology of mo-v-te-nb-o and catalysts, which is applied in chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve problems such as price impact, and improve selectivity and yield , Improve stability and catalytic activity, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A method for preparing a Mo-V-Te-Nb-O catalyst provided by an aspect of the embodiments of the present invention includes:

[0021] Heating and oxidizing low-grade tellurium raw materials to obtain tellurium oxides;

[0022] reducing the tellurium oxide with a reducing agent to obtain a sub-micron tellurium source;

[0023] React sub-micron tellurium sources, molybdenum sources, vanadium sources, and niobium sources in a solvent to obtain catalyst precursors;

[0024] The catalyst precursor is dried and calcined to prepare a Mo-V-Te-Nb-O catalyst.

[0025] In some embodiments, the preparation method specifically includes: heating low-grade tellurium powder in the presence of oxygen, thereby oxidizing to obtain tellurium oxide.

[0026] Further, the raw material used in the present invention may be low-grade metal tellurium powder, and the particle size of the low-grade metal tellurium powder may be below 5.0 μm, preferably below 2.0 μm. The purity of low-grade metal ...

Embodiment 1

[0085] A kind of Mo-V-Te-Nb-O series catalyst of this embodiment is prepared by following steps 1)~step 3):

[0086] 1) Mixing and drying: add 370.8g ammonium tetramolybdate and 65.4g ammonium metavanadate in 900g distilled water, stir and dissolve at 80°C, then add liquid A and 576g concentration of ammonia water of 2.0wt%, continue stirring for 2 hours, When the temperature of the reaction system drops to 50°C, keep stirring, and add liquid B to obtain a viscous precipitate, keep stirring for 5 minutes, then add 960g of ammonium nitrate to the reaction system, continue stirring, and finally spray the obtained slurry Dry to powder.

[0087] Wherein liquid A and liquid B can be prepared by the following methods, including:

[0088] 35.5 g of tellurium metal powder with a purity of 99% and an average particle size of 3.0 μm was charged into a crucible, and heated at 300° C. for 10 hours in a muffle furnace to obtain 45.8 g of gray powder. The obtained gray powder was added to...

Embodiment 2

[0095] The preparation process of a kind of Mo-V-Te-Nb-O series catalyst of this embodiment is basically the same as that of Example 1, the difference is:

[0096] In step 1), the heating temperature of the metal tellurium powder is 350°C.

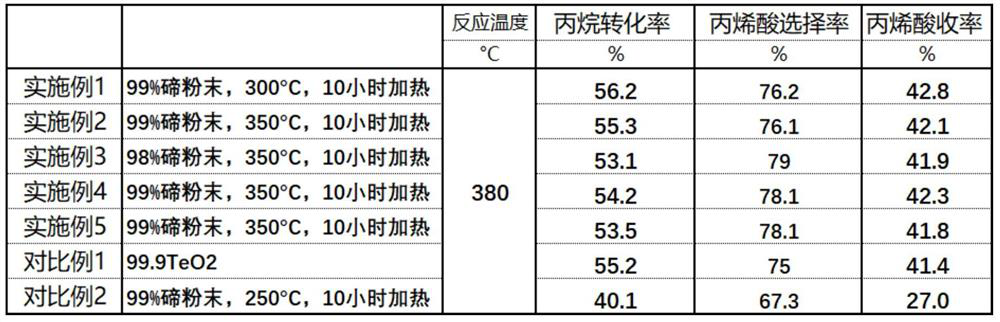

[0097] The conversion rate of propane and the yield of acrylic acid of the prepared catalyst were evaluated under the same reaction conditions, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com