System and process for preparing SCR (Selective Catalytic Reduction) denitration catalyst from Fenton iron mud

A denitrification catalyst and iron slime technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., to achieve the effects of low cost, improved thermal efficiency, and reasonable equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

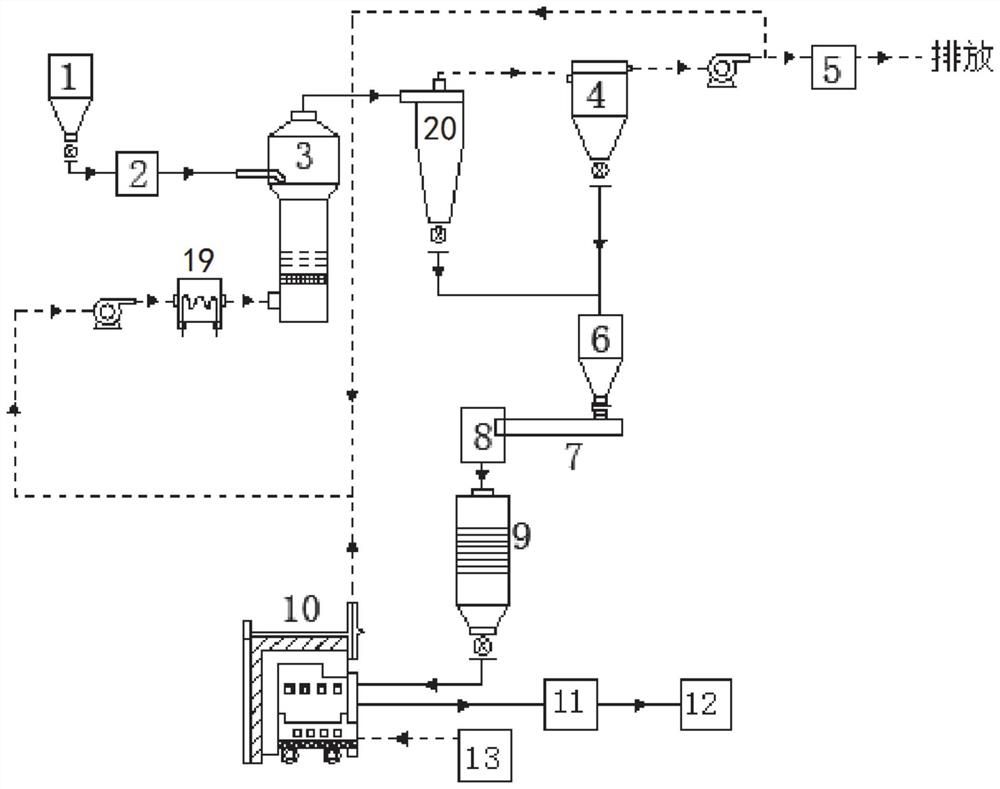

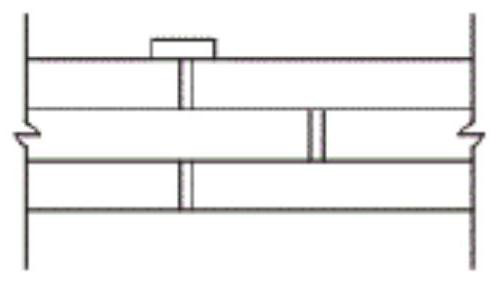

[0054] figure 1 Among them, a system and process for preparing SCR denitrification catalyst from Fenton iron sludge, the outlet of hopper I1 is connected to the feed port of carrier fluidized bed dryer 3 through sludge pump 2, and the outlet of carrier fluidized bed dryer 3 is connected to the feed port of carrier fluidized bed dryer 3 The feed port of the bin II6 is connected, the discharge port of the bin II6 is connected with the feed port of the strong mixer 8 through the screw conveyor 7, the discharge port of the strong mixer 8 is connected with the feed port of the vacuum extruder 9, and the vacuum The discharge port of the extruder 9 is connected to the feed port of the shuttle kiln 10 , the discharge port of the shuttle kiln 10 is connected to the cutting machine 11 , and the cutting machine 11 is connected to the module area 12 .

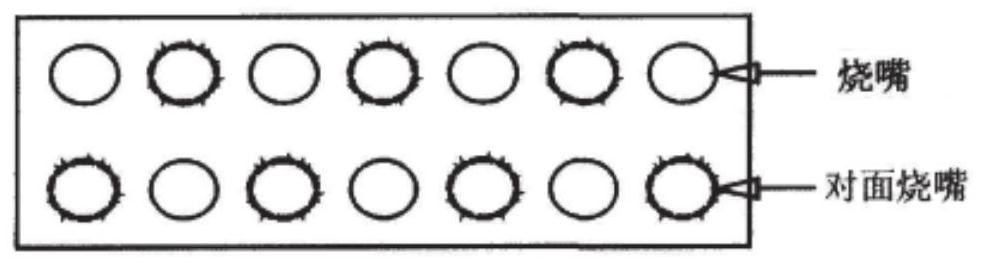

[0055] The flue gas outlet of the burner 13 is connected to the shuttle kiln 10, the tail gas outlet of the shuttle kiln 10 is connected ...

Embodiment 2

[0064] A system for preparing SCR denitrification catalyst from Fenton iron slime, including: hopper I1, carrier fluidized bed dryer 3, dust removal devices 4, 19, wet desulfurization and denitrification device 5, hopper II6, mixer 8, vacuum extrusion Discharge machine 9, shuttle kiln 10, cutting machine 11, module area 12, burner 13; the silo I1, carrier fluidized bed dryer 3, dust removal device 4, 19, wet desulfurization and denitrification device 5 are connected in sequence; The dust removal ports of the dust removal devices 4 and 19 and the discharge port of the carrier fluidized bed dryer 3 are respectively connected to the feed port of the feed bin II6, and the feed bin II6 is connected to the mixer 8, the vacuum extruder 9, the shuttle kiln 10, cutting machine 11, and module area 12 are connected in sequence, the flue gas outlet of the burner 13 is connected with the gas inlet of the shuttle kiln 10, the exhaust gas outlet of the shuttle kiln 10 is connected with the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com