Three-layer co-extrusion mute drain pipe as well as preparation method and application thereof

A technology of three-layer co-extrusion and drainage pipes, which is applied in applications, other household appliances, chemical instruments and methods, etc., can solve the problems that silent pipes cannot have a good quiet effect at the same time, and are not easy to age and deteriorate, so as to meet the requirements of rapid construction, It is not easy to age, and the effect of improving compactness and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

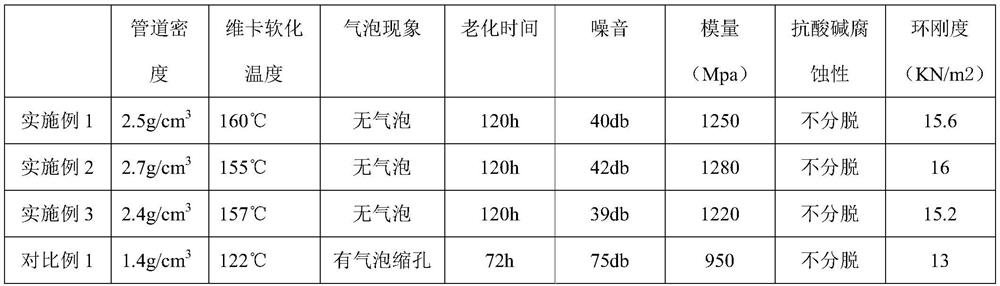

Embodiment 1

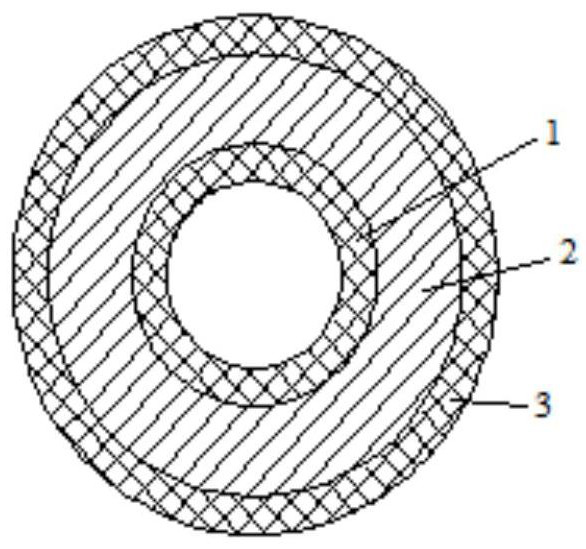

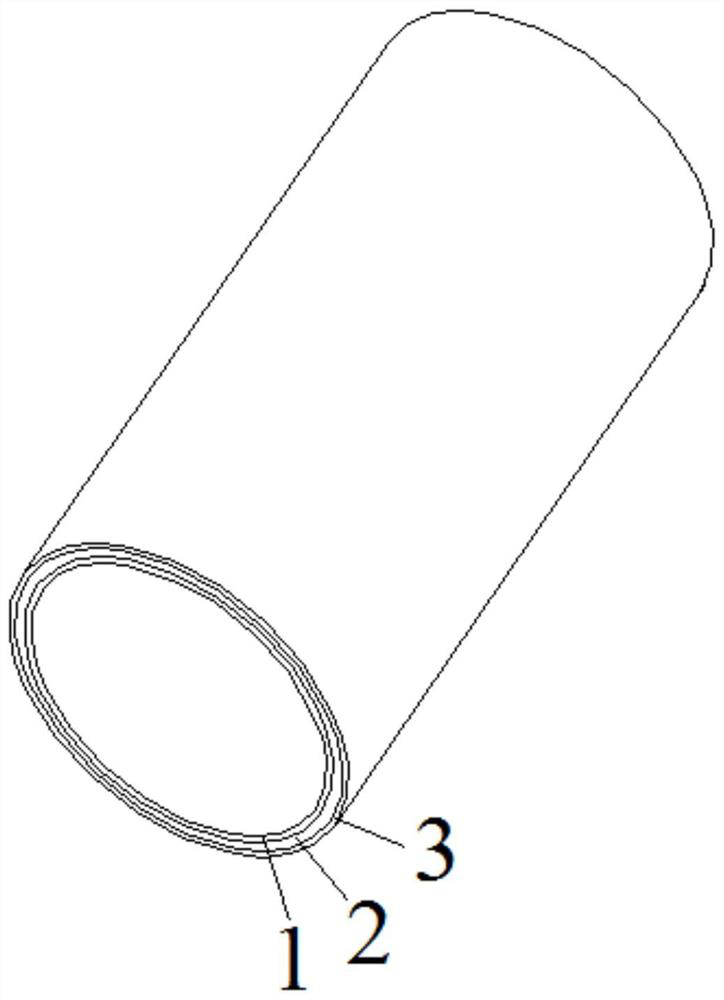

[0036] A three-layer co-extruded silent drainage pipe, comprising an outer layer, a middle core layer, and an outer layer; the outer layer includes components calculated in parts by weight: 40 parts of polypropylene, 1 part of color masterbatch, and 8 parts of phenolic antioxidant agent and 0.15 parts of calcium zinc stabilizer;

[0037] The middle core layer includes components calculated in parts by weight: 7 parts of polypropylene resin, 2 parts of calcium carbonate and 0.01 part of defoamer;

[0038] The inner layer includes components calculated in parts by weight: 45 parts of polypropylene and 0.3 part of white masterbatch.

[0039] The preparation method of the above-mentioned three-layer co-extruded silent drainage pipe comprises the following steps:

[0040] After heating the inner layer raw materials to a temperature of 190°C, melt and extrude the linear raw materials through a granulator, pass through an automatic pelletizer after cooling through water to form inne...

Embodiment 2

[0044] A three-layer co-extruded silent drainage pipe, comprising an outer layer, a middle core layer, and an outer layer; the outer layer includes components calculated in parts by weight: 35 parts of polypropylene, 0.5 parts of color masterbatch, and 7 parts of phenolic antioxidant agent and 0.05 parts of calcium zinc stabilizer;

[0045] The middle core layer includes components calculated in parts by weight: 1 part of broken pipe material of three-layer co-extruded silent drainage pipe, 0.5 part of barium sulfate and 0.01 part of defoamer;

[0046]The inner layer includes components calculated in parts by weight: 60 parts of polypropylene and 1.3 parts of white masterbatch.

[0047] The preparation method of the above-mentioned three-layer co-extruded silent drainage pipe comprises the following steps:

[0048] After heating the inner layer raw materials to a temperature of 180°C, melt and extrude the linear raw materials through a granulator, pass through an automatic pe...

Embodiment 3

[0052] A three-layer co-extruded silent drainage pipe, comprising an outer layer, a middle core layer, and an outer layer; the outer layer includes components calculated in parts by weight: 45 parts of polypropylene, 1.5 parts of color masterbatch, and 9 parts of phenolic antioxidant agent and 0.15 parts of calcium zinc stabilizer;

[0053] The middle core layer includes components calculated in parts by weight: 8 parts of polypropylene resin, 3 parts of calcium carbonate and 0.015 parts of defoamer;

[0054] The inner layer includes components calculated in parts by weight: 50 parts of polypropylene and 1 part of white masterbatch.

[0055] The preparation method of the above-mentioned three-layer co-extruded silent drainage pipe comprises the following steps:

[0056] The raw material for the inner layer is polypropylene granules plus white masterbatch. After the above material is heated to a temperature of 200°C, the linear raw material is melted and extruded through a gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com