System and method for preparing taurine

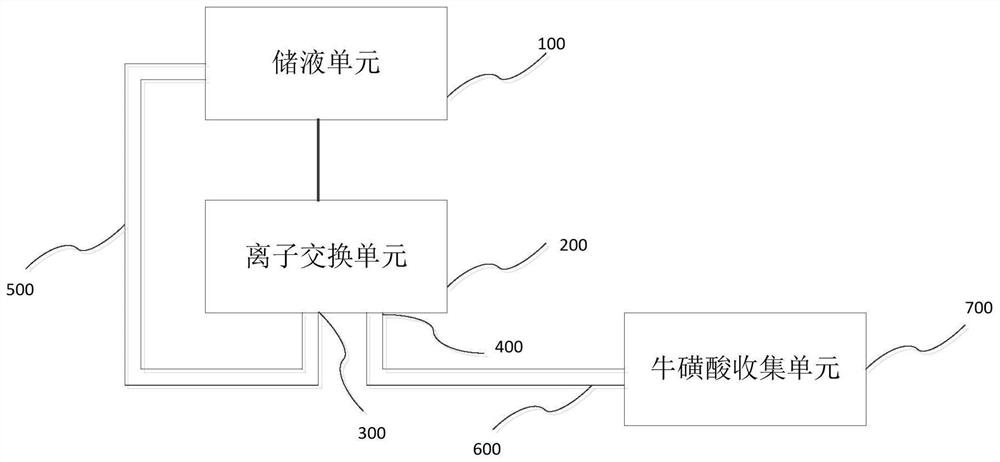

A technology of taurine and isethionic acid, applied in the field of chemical engineering, can solve problems such as low efficiency and complicated taurine process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

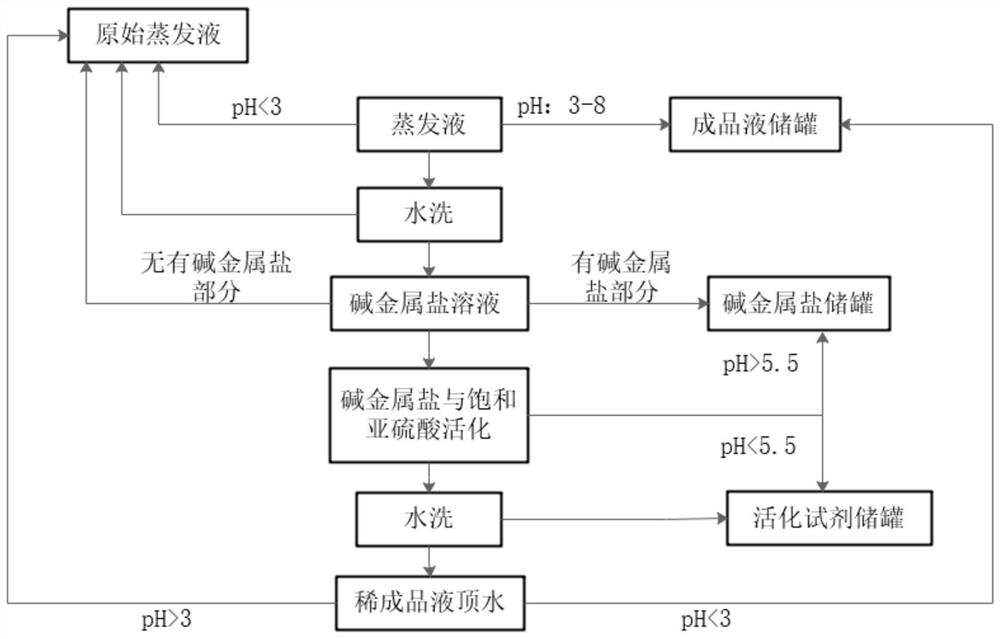

[0059] Utilize sulfur dioxide saturated solution to activate the cation exchange resin system to produce taurine, wherein the circulation procedure is after the resin is fully activated: the diluted evaporation liquid is fed into the ion exchange column, and when the pH value of the effluent begins to increase, the effluent is collected, When the pH of the effluent reaches about 8, stop entering the evaporative liquid; wash the ion exchange column with water until the pH of the effluent is 4 to 6, stop entering water; activate the ion exchange column with saturated sulfurous acid solution, and after the activation is complete, use water Wash the ion exchange column again until the pH of the effluent is about 5, stop the water washing, and enter the next cycle. The specific steps are as follows:

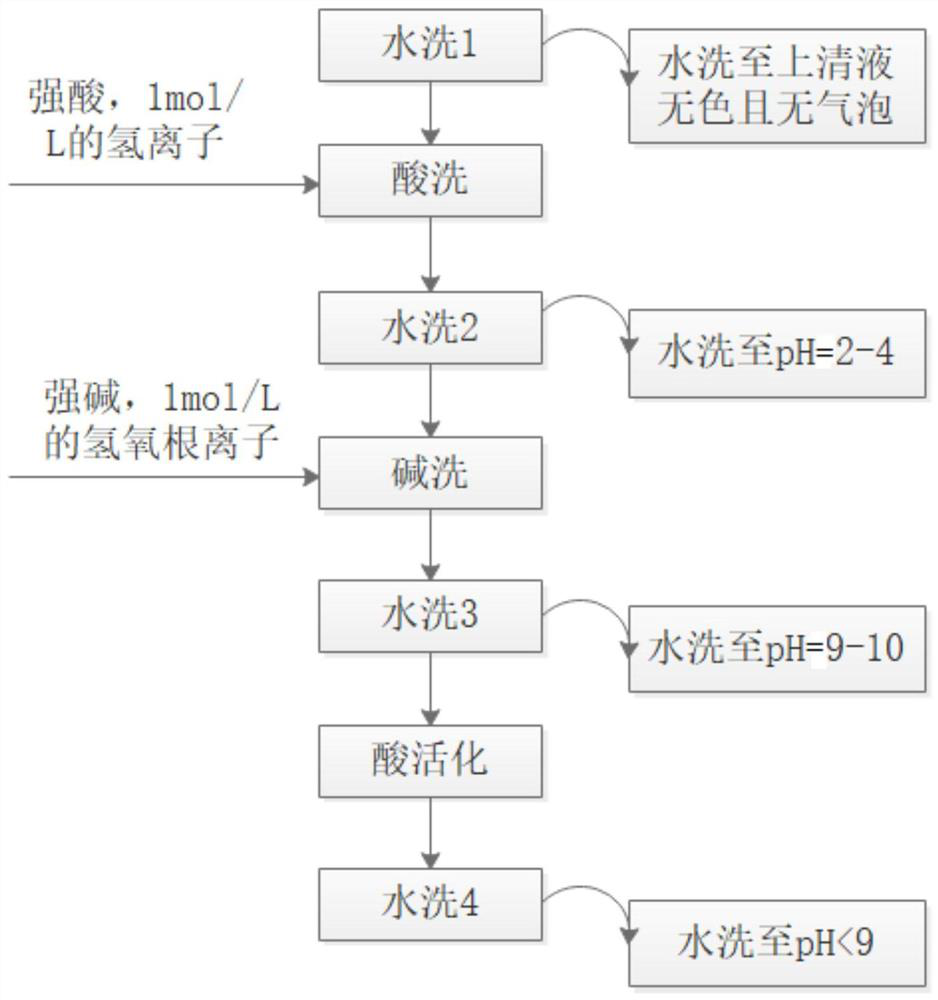

[0060] S1, resin pre-activation treatment: take 4L of resin and put it into the chromatographic column to be firm, keep 3-5cm of water on the upper part of the resin, and treat the res...

Embodiment 2

[0068] The system of the invention is used to produce taurine, the concentration of taurine alkali metal salt in the evaporation liquid is controlled to be 15wt%, 20wt% and 25wt%, the sample injection temperature is 60°C to 70°C, and the saturated solution of sulfurous acid and the concentration of Activated the mixture of 45 wt% sodium bisulfite solution, detected and controlled the taurine injection amount, taurine conversion rate, purification purity under the same conditions, single cycle time, water demand and resin column under the same pH endpoint value Available times.

[0069] The specific experimental steps are as follows:

[0070] S1, resin pre-activation treatment: take 4L of resin and put it into the chromatographic column to be firm, keep 3-5cm of water on the upper part of the resin, and treat the resin with 2-4 times of the sulfuric acid solution with a volume content of 4wt% of the resin, and the flow rate is 1.5-5BV / h, after the end, wash the resin with wat...

Embodiment 3

[0079] S1. Resin packing: Use 1L of resin to be sturdy, transfer it to the resin column with deionized water, and retain 3-5cm of water on the upper part of the resin.

[0080] S2. Resin pre-activation treatment: Treat the resin with 4wt% sulfuric acid solution 3 times the resin volume, the flow rate is 1.5~5BV / h, after the end, wash the resin with water until the outlet pH>4, and then use 4wt% NaOH solution 2~4 times the resin volume , 1.5 ~ 5BV / h flow rate to transform the resin, after the end, wash the resin with water to the outlet pH4, and the resin activation is completed for subsequent use.

[0081] S3. Evaporation liquid sample is passed through the column: take the pretreated resin and transfer it to the chromatography column, and the evaporation liquid with a sodium taurine content of 20wt% is adsorbed through the column according to a certain flow rate, and the end point is determined according to the requirements of different time periods. various indicators. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com