Method for preparing cobalt salt through low-cost resourceful treatment of cobalt intermediate products and waste battery materials

A resource-based, low-cost technology, applied in the direction of cobalt sulfate, process efficiency improvement, etc., can solve the problems of difficult battery-grade cobalt salt product quality requirements, non-normal production, excessive waste water discharge, etc., to eliminate non-normal production and production. The effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

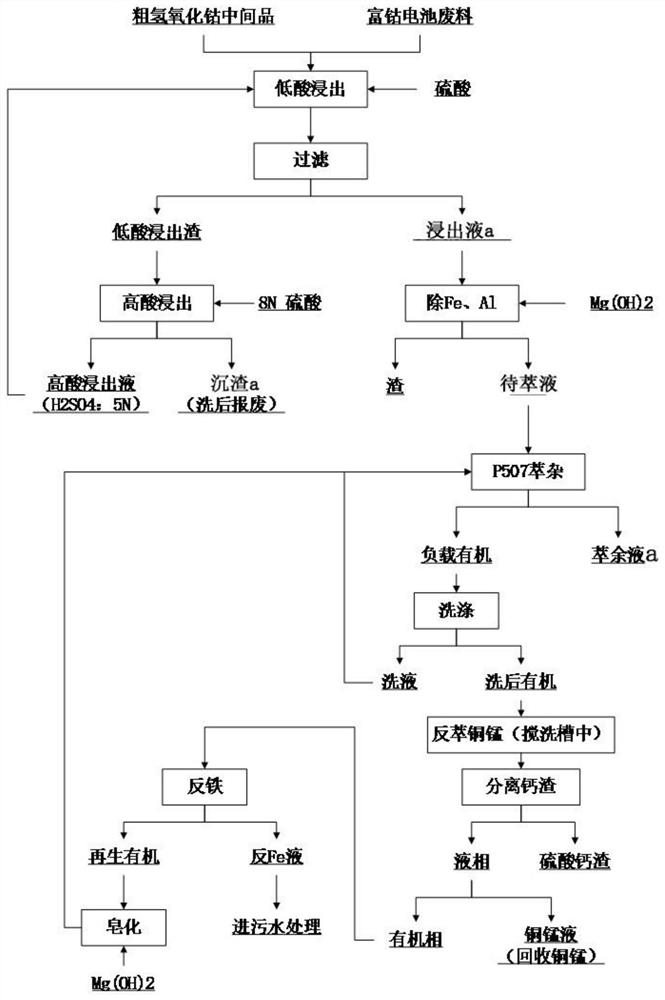

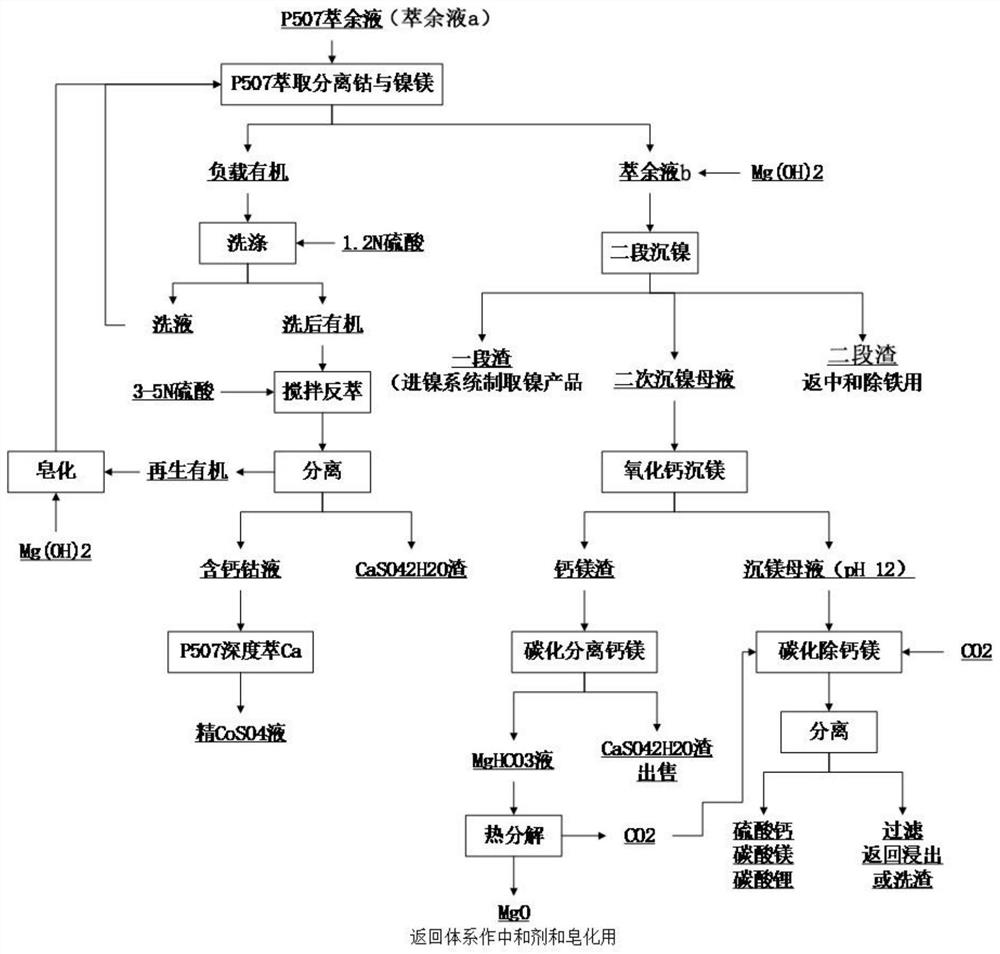

[0028] Such as figure 1 or figure 2 As shown, the method for producing cobalt salts from low-cost resource processing cobalt intermediate products and waste battery materials of the present invention comprises:

[0029] S01, using acid leaching method to carry out acid leaching treatment on the crude cobalt intermediate product and cobalt-rich battery waste, and obtain the leaching solution a with an end point pH value of 1.0-1.5;

[0030] Wherein, step S01 specifically includes:

[0031] S011. Under the condition of 70±3°C, use sulfuric acid to carry out acid leaching treatment on the crude cobalt intermediate product and cobalt-rich battery waste, so that precipitates are formed in the acid leaching solution. When the final pH value of the acid leaching solution is 1.0-1.5, Filtration and separation to obtain leach solution A and low-acid leach residue with an end point pH value of 1.0 to 1.5;

[0032] S012. Under the condition of 85-90°C, use 8N sulfuric acid to carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com