ZnS-SnS@3DC composite material and preparation method and application thereof

A composite material, zns-sns technology, applied in nanotechnology for materials and surface science, chemical instruments and methods, tin compounds, etc., can solve problems such as volume expansion, active material shedding, and battery cycle stability deterioration , to achieve long cycle life, high specific capacity, and improve cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1)N 2 Under the atmosphere, the metal-organic framework ZIF-8 was carbonized at 900°C for 5 hours to obtain a nitrogen-doped three-dimensional porous carbon framework;

[0038] (2) Mix Sn powder, S powder and nitrogen-doped three-dimensional porous carbon framework to obtain a mixture, wherein the mass ratio of Sn powder and S powder is 3.6:1, and the mass of Sn powder and S powder accounts for 43% of the total mass of the mixture ; Then the mixture was sealed in a quartz tube with a vacuum degree of 0.1Pa, and calcined at 700° C. for 2 hours to obtain a ZnS-SnS@3DC composite material.

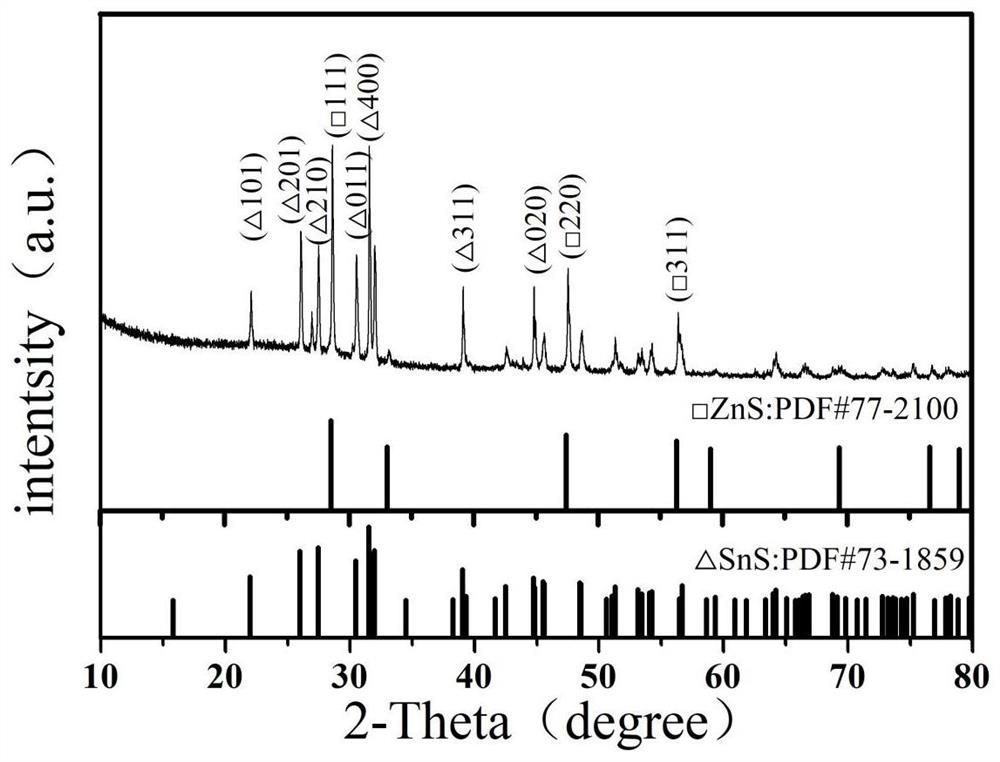

[0039] Such as figure 1As shown, in the vicinity of 28, 47, and 56 degrees on the abscissa 2θ, there are three diffraction peaks of ZnS, corresponding to (111) (220) (311) crystal planes; , 29, 30, 39, and 45 degrees are the diffraction peaks of SnS, corresponding to the (101)(201)(210)(011)(400)(311)(020) crystal plane.

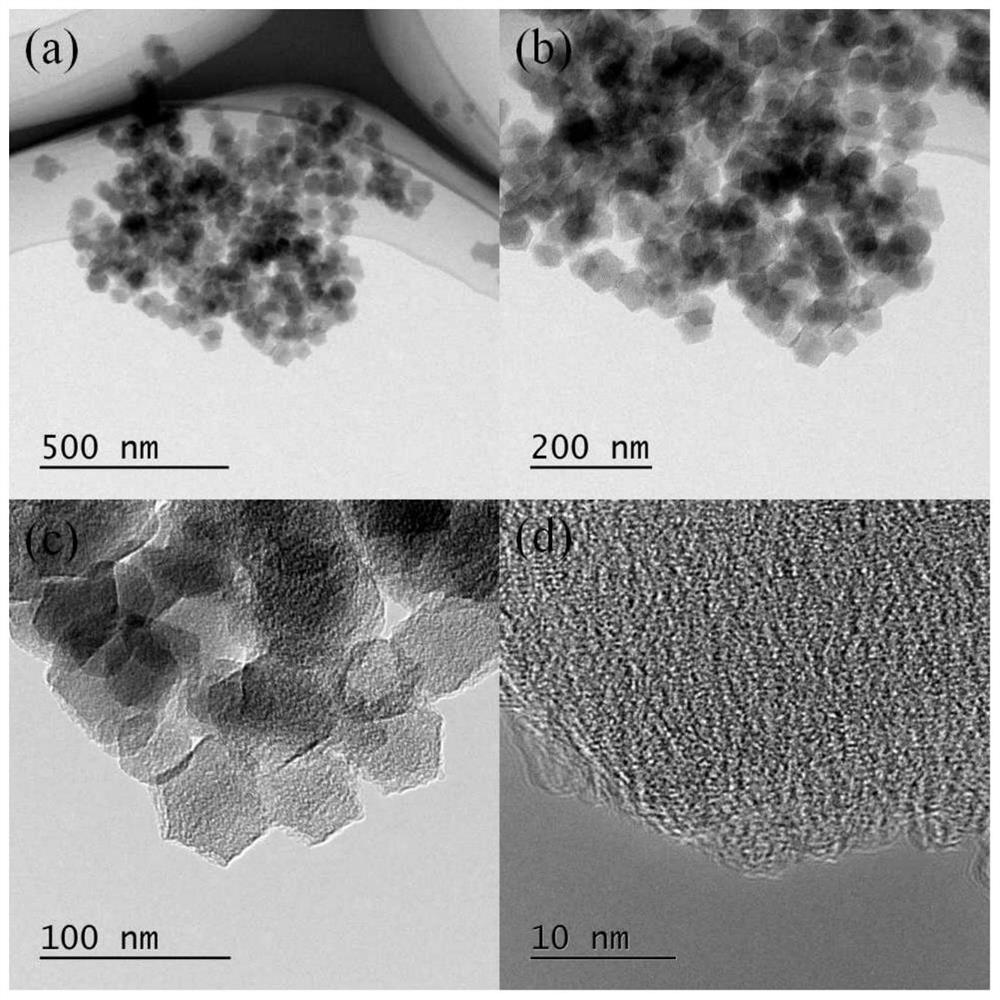

[0040] Such as figure 2 As shown in Figure (c) (d), it can...

Embodiment 2

[0048] (1)N 2 Under the atmosphere, the metal-organic framework ZIF-8 was carbonized at 800°C for 3 hours to obtain a nitrogen-doped three-dimensional porous carbon framework;

[0049] (2) Mix Sn powder, S powder and nitrogen-doped three-dimensional porous carbon framework to obtain a mixture, wherein the mass ratio of Sn powder and S powder is 3.6:1, and the mass of Sn powder and S powder accounts for 25% of the total mass of the mixture ; Then the mixture was sealed in a quartz tube with a vacuum degree of 1 Pa, and calcined at 900° C. for 3 h to obtain a ZnS-SnS@3DC composite material. battery at 100mA g -1 After running 100 cycles under the current density, the specific capacity is 732mA h g -1 ; The Coulombic efficiency is stable at about 99.0%; it is used as the negative electrode material of the sodium ion battery, and the battery is stable at 100mA g -1 After 50 laps at current density, it is 198mA h g -1 , the Coulombic efficiency is stable at around 97%.

Embodiment 3

[0051] (1)N 2 Under the atmosphere, the metal-organic framework ZIF-8 was carbonized at 850°C for 5 hours to obtain a nitrogen-doped three-dimensional porous carbon framework;

[0052] (2) Mix Sn powder, S powder and nitrogen-doped three-dimensional porous carbon framework to obtain a mixture, wherein the mass ratio of Sn powder and S powder is 3.6:1, and the mass of Sn powder and S powder accounts for 65% of the total mass of the mixture ; Then the mixture was sealed in a quartz tube with a vacuum degree of 0.5 Pa, and calcined at 800° C. for 1 h to obtain a ZnS-SnS@3DC composite material. battery at 100mA g -1 After running 250 cycles under the current density, the specific capacity is 710mA h g -1 ; The Coulombic efficiency is stable at about 99.1%; it is used as the negative electrode material of the sodium ion battery, and the battery is stable at 100mA g -1 After running 40 laps under the current density, the specific capacity is 203mA h g -1 , the Coulombic efficien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com