Transition metal-N/C composite magnesium-based hydrogen storage material and preparation method thereof

A technology of hydrogen storage material and composite material, which is applied in the field of transition metal-N/C composite magnesium-based hydrogen storage material and its preparation, can solve the problem that it cannot withstand ball milling treatment, the alloy is difficult to refine, and it is easy to adhere to the grinding ball and It can improve the reversible hydrogen storage characteristics, increase the brittleness and improve the efficiency of ball milling.

Inactive Publication Date: 2021-07-13

TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, magnesium-based hydrogen storage alloys have a certain degree of toughness and ductility, which makes them easy to adhere to the grinding balls and tank walls when they are treated by ball milling, making them in fact unable to withstand sufficient ball milling.

More importantly, its cold welding rate is much greater than its fracture rate, making it difficult to refine the alloy, requiring higher energy and power to refine it

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

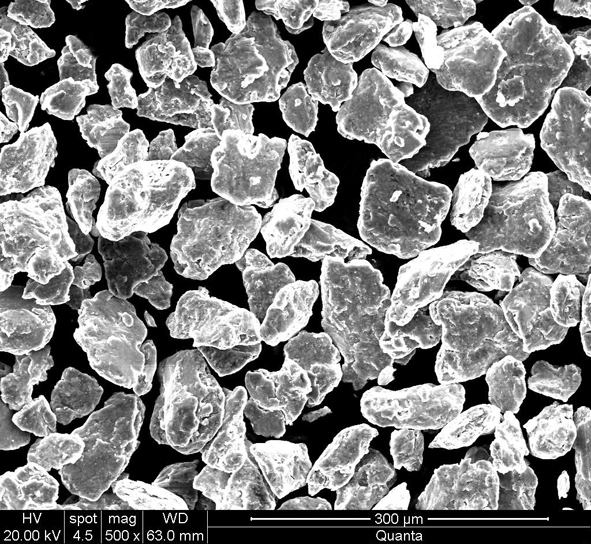

[0034] Embodiment 1: Mg+10wt.%Ce;

Embodiment 2

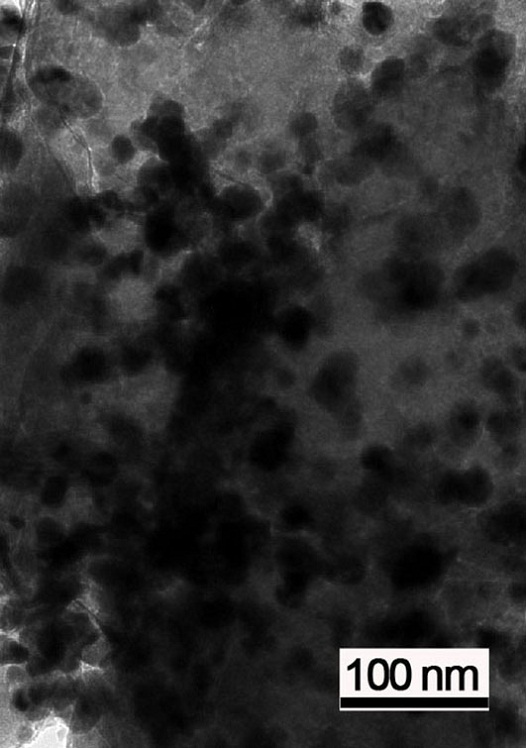

[0035] Embodiment 2: Fe-N / C composite material;

Embodiment 3

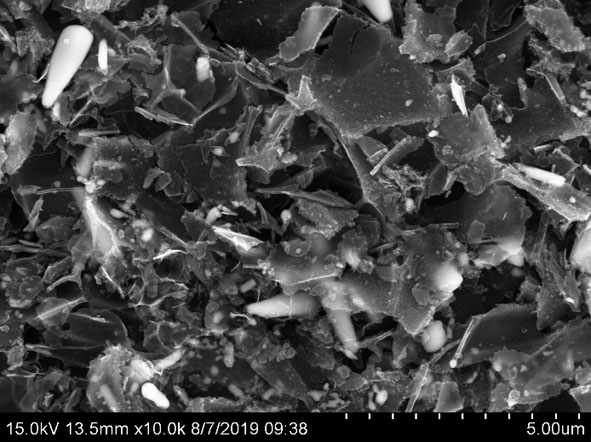

[0036] Embodiment 3: (Mg+10wt.%Ce)+3wt.%Fe-N / C;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a transition metal-N / C composite magnesium-based hydrogen storage material and a preparation method thereof, belonging to the technical field of hydrogen storage materials. The main component of the hydrogen storage material is magnesium, and the hydrogen storage material is prepared by synergistic catalysis of rare earth, transition metal nitrate and a nitrogenous polyvinylpyrrolidone polymer, and has a nanocrystalline structure and excellent low-temperature hydrogen absorption and desorption dynamic performance. The preparation method of the hydrogen storage material comprises the following steps: preparing a magnesium-rare earth as-cast hydrogen storage alloy, preparing a transition metal-N / C composite material, compounding the magnesium-rare earth as-cast hydrogen storage alloy and the transition metal-N / C composite material by using a mechanical ball milling method, performing cooling, and carrying out low-temperature passivation to obtain the transition metal-N / C composite magnesium-based hydrogen storage material. According to the invention, rare earth elements are added into magnesium, the reversible hydrogen storage characteristic of the magnesium is greatly improved through the synergistic catalysis effect of the rare earth elements, carbon, nitrogen and transition metal, the wall sticking phenomenon in a mechanical ball milling process is overcome, the recovery rate of the material is increased, and the high-capacity magnesium-based composite hydrogen storage material with the excellent low-temperature hydrogen absorption performance is obtained.

Description

technical field [0001] The invention belongs to the technical field of hydrogen storage materials, and in particular relates to a transition metal-N / C composite magnesium-based hydrogen storage material and a preparation method thereof. Background technique [0002] Hydrogen energy has been extensively studied as a clean, efficient, and safe new energy source, but how to store hydrogen energy safely and efficiently is still a key issue in hydrogen energy applications, compared with traditional gaseous hydrogen storage and liquid hydrogen storage , The solid hydrogen storage material can not only store hydrogen effectively, but also avoid the consumption, leakage and safety problems of hydrogen gas during use. However, among numerous solid-state hydrogen storage materials, only light metals such as Mg can have a high hydrogen storage specific gravity, which is very important for the development of hydrogen storage functional systems that can cover an actual mileage greater th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B3/00B22F9/04C22C1/02C22C23/06

CPCC01B3/0078C22C23/06C22C1/02B22F9/04B22F2009/043Y02E60/32

Inventor 雍辉胡季帆王帅马江微崔燕

Owner TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com