Lithium iron phosphate material as well as preparation method and application thereof

A technology of lithium iron phosphate and iron phosphate, which is applied in the field of lithium-ion battery cathode materials, can solve the problems of the limit of nanometerization, low energy utilization rate, and high energy consumption, so as to reduce the difficulty of nanometerization, improve the energy density of batteries, and The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

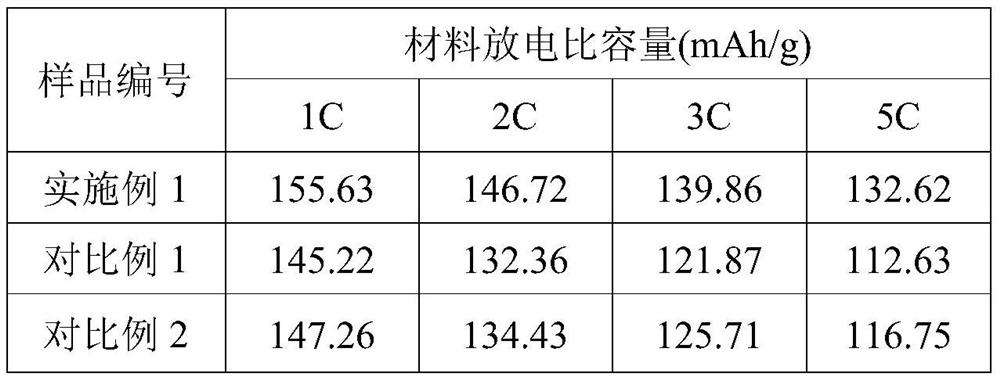

Examples

preparation example Construction

[0024] The first aspect of the present invention provides a method for preparing a lithium iron phosphate material, comprising the following steps:

[0025] Mix and stir the ferric phosphate and the organic acid solution to obtain a mixed solution;

[0026] Grinding the mixed solution until the iron phosphate particle size D50≤150nm, then mixing and stirring it with lithium carbonate and carbon source to obtain a slurry;

[0027] The slurry is dried, granulated, and calcined to obtain a lithium iron phosphate material.

[0028] The preparation method utilizes that organic acids can ionize hydrogen ions and iron phosphate has the characteristics of being easily dissociated under the action of hydrogen ions. First, lithium iron phosphate is mixed and ground with an organic acid solution. Since the organic acid ionizes hydrogen ions, lithium iron phosphate It is easier to be ground, so that the iron phosphate particles can quickly reach the required degree of nanometerization un...

Embodiment 1

[0039] The preparation method of lithium iron phosphate in the present embodiment specifically comprises the following steps:

[0040] Weigh 1000kg of ferric phosphate and add it into 1500L of acetic acid solution with a concentration of 0.05mol / L, and stir for 0.5h to obtain a mixed solution;

[0041] After the mixed solution was ground to D50=100-150nm by a sand mill, 249kg of lithium carbonate and 110kg of glucose monohydrate were added thereto, and after stirring for 1 hour, a slurry was obtained;

[0042] The slurry is dried and granulated by a centrifugal spray dryer to obtain a lithium iron phosphate precursor;

[0043] The lithium iron phosphate precursor is calcined in a nitrogen-protected atmosphere furnace at a temperature of 620°C for 5 hours to obtain a lithium iron phosphate material; if necessary, the lithium iron phosphate material can be crushed into a required particle size by a jet mill .

Embodiment 2

[0055] The difference between the preparation method of the lithium iron phosphate material in this example and Example 1 is that in the step of obtaining the mixed solution, the concentration of the acetic acid solution is 0.09 mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com