Method for preparing 2, 2-bis (3-nitro-4-hydroxyphenyl) hexafluoropropane by microchannel reactor

A microchannel reactor, hydroxyphenyl technology, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, preparation of nitro compounds, etc. Exacerbating problems such as rapid reaction, avoiding intermediate separation steps, and reducing by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

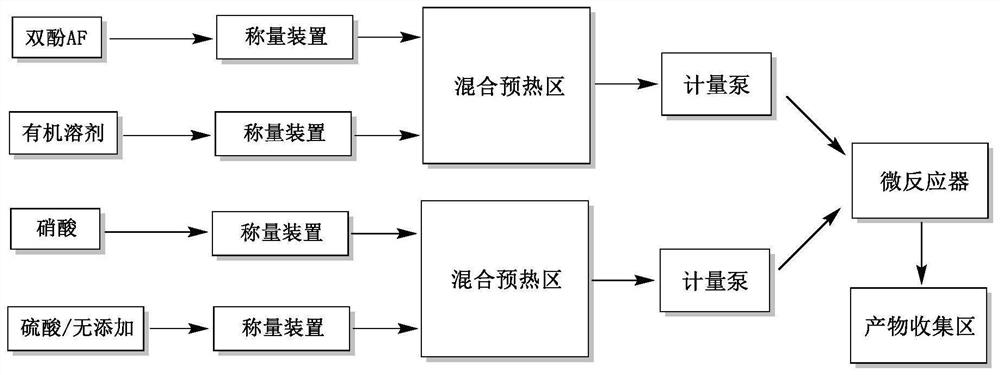

[0030] (1) Refer to figure 1 Determine the connection method, the heat transfer medium of the heat exchanger is heat transfer oil. The diameter of the microchannel reactor is 0.5mm.

[0031] (2) 150g of bisphenol AF and 600g of dichloromethane were mixed and stirred to form a bisphenol AF solution; 86g of nitric acid (concentration 65%) and 172g of sulfuric acid (concentration 98%) were prepared into a mixed acid solution. After the two systems were preheated at 0°C, they were pumped into the microchannel reactor through the metering pump at the flow rate of 25g / min and 8.6g / min respectively. At this time, the molar ratio of bisphenol AF to mixed acid was 1:2, and the reaction temperature was controlled The temperature is 45°C, the residence time is 30s, and the temperature of the reaction product is lowered through the cooling coil to obtain a discharge liquid containing 2,2-bis(3-nitro-4-hydroxyphenyl)hexafluoropropane.

[0032] (3) Add 1 L of 5% sodium bicarbonate solutio...

Embodiment 2

[0035] (1) Refer to figure 1 Determine the connection method, the heat transfer medium of the heat exchanger is heat transfer oil. The diameter of the microchannel reactor is 3mm.

[0036] (2) 150g of bisphenol AF and 750g of dichloroethane were mixed and stirred to form a bisphenol AF solution; 108g of nitric acid (concentration 65%) and 324g of sulfuric acid (concentration 95%) were prepared into a mixed acid solution. After the two systems were preheated at 10°C, they were pumped into the microchannel reactor at the flow rate of 15g / min and 7.2g / min respectively through the metering pump. At this time, the molar ratio of bisphenol AF to nitric acid was 1:2.5, and the reaction temperature was controlled The temperature is 30°C, and the residence time is 60s. The temperature of the reaction product is lowered through the cooling coil to obtain a discharge liquid containing 2,2-bis(3-nitro-4-hydroxyphenyl)hexafluoropropane.

[0037] (3) Add 1 L of 5% sodium bicarbonate solut...

Embodiment 3

[0039] (1) Refer to figure 1 Determine the connection method, the heat transfer medium of the heat exchanger is heat transfer oil. The diameter of the microchannel reactor is 5mm.

[0040] (2) 150g of bisphenol AF and 900g of chloroform were mixed and stirred to form a bisphenol AF solution; 120g of nitric acid (concentration 70%) and 480g of sulfuric acid (concentration 90%) were prepared into a mixed acid solution. After the two systems were preheated at 20°C, they were pumped into the microchannel reactor at the flow rate of 11.7g / min and 6.7g / min respectively through the metering pump. At this time, the molar ratio of bisphenol AF to nitric acid was 1:3, and the reaction was controlled The temperature was 15° C., and the residence time was 90 s. The temperature of the reaction product was lowered through a cooling coil to obtain a discharge liquid containing 2,2-bis(3-nitro-4-hydroxyphenyl)hexafluoropropane.

[0041](3) Add 1 L of 5% sodium bicarbonate solution to the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com