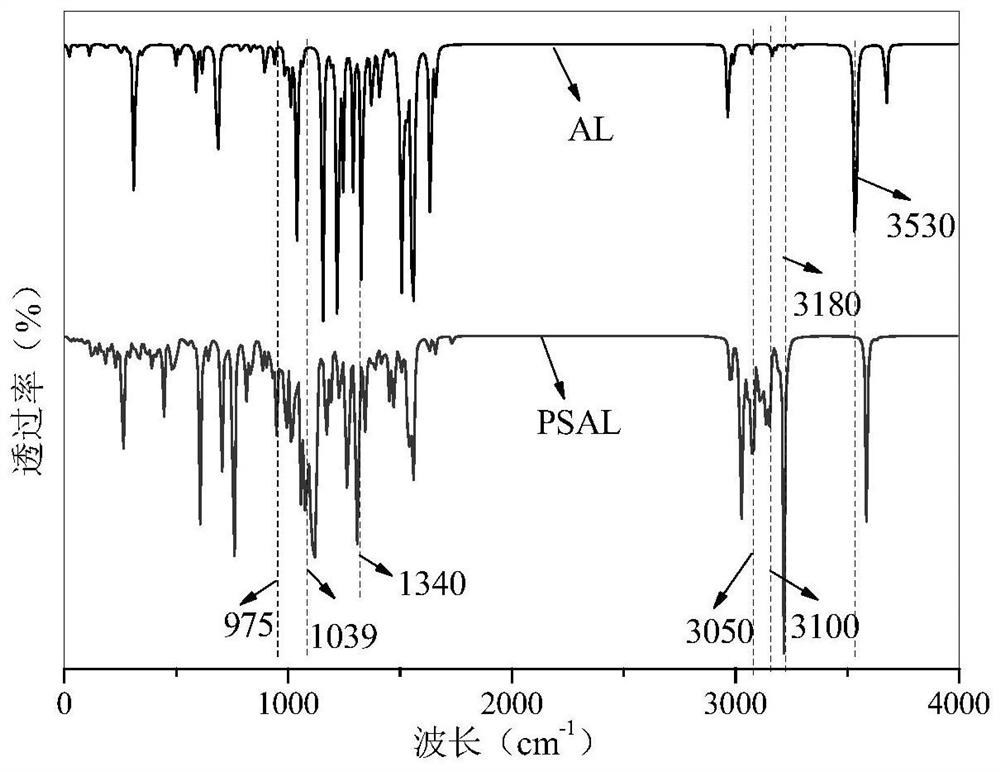

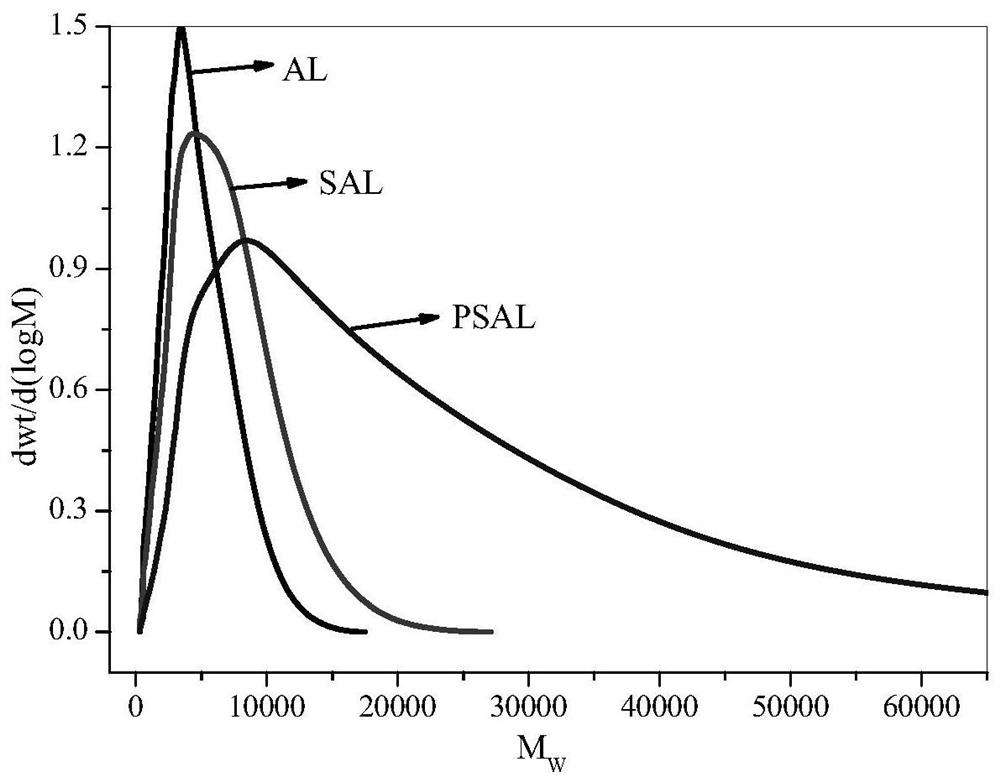

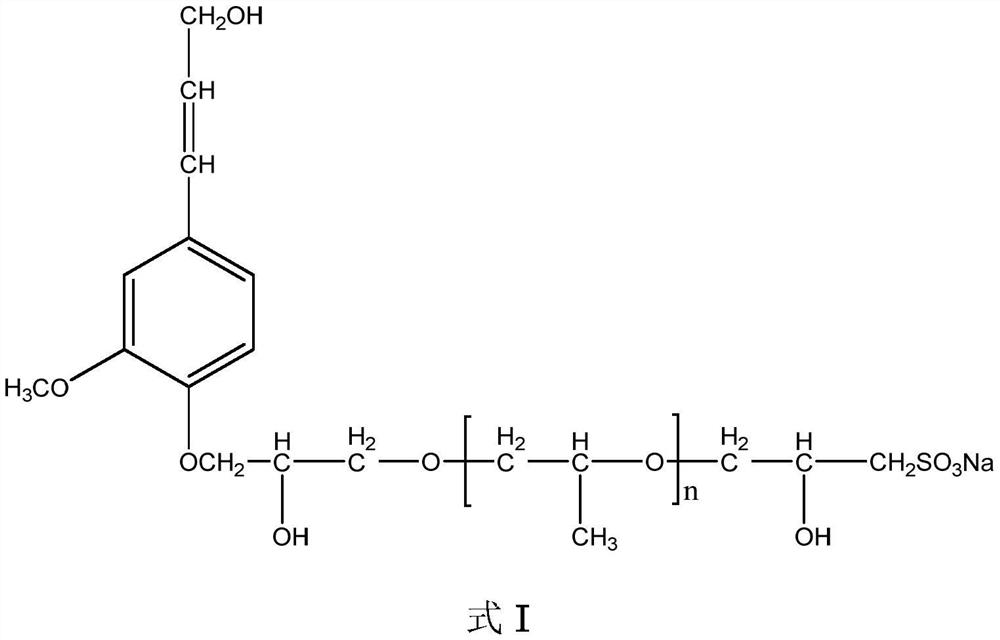

A kind of lignin polyoxypropylene ether sulfate and its preparation method and application as dispersant

A polyoxypropylene ether and lignin technology, applied in the preparation, application, dyeing and other directions of sulfonate, can solve the problem of poor application performance, inability to provide, and multiple hydrophobic adsorption sites of end-group sulfonate-type lignin polyether and other problems, to achieve the effect of high adsorption fastness, small damage and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of lignin polyoxypropylene ether sulfate, comprising the following steps:

[0042] 100g of alkali lignin was dissolved in alkaline aqueous solution (pH value 11) to obtain a lignin solution with a concentration of 20%; 50g of polypropylene glycol glycidyl ether (molecular weight=600) was dissolved in 100g of acetone to obtain a homogeneous solution. Mix the above-mentioned lignin solution and polypropylene glycol glycidyl ether solution together, add 10 g of sodium p-toluenesulfonate, stir and mix to form a homogeneous semi-water-based system. Then, hydrochloric acid aqueous solution was added to adjust the pH of the reaction solution to 4, and the reaction was incubated at 90° C. for 1 hour; 50 g of sodium sulfite was then added, and the reaction was incubated at 90° C. for 2 hours. The pH of the product is adjusted to 6 by adding aqueous sodium hydroxide solution, and the solvent is distilled off to obtain the lignin polyoxypropylene ether sulfate...

Embodiment 2

[0049] A preparation method of lignin polyoxypropylene ether sulfate, comprising the following steps:

[0050] Dissolve 90g of enzymatic lignin in alkaline aqueous solution (pH value 12) to obtain a lignin solution with a concentration of 25%; dissolve 20g of polypropylene glycol glycidyl ether (molecular weight=400) in 90g of butanone to obtain a homogeneous solution. Mix the above-mentioned lignin solution and polypropylene glycol glycidyl ether solution together, add 9g of potassium p-toluenesulfonate, stir and mix to form a homogeneous semi-water-based system. Then add sulfuric acid aqueous solution to adjust the pH of the reaction solution to 3, keep the reaction at 85° C. for 2 hours; then add 45 g of potassium sulfite, and keep the reaction at 80° C. for 3 hours. Add sodium hydroxide aqueous solution to adjust the pH of the product to 7, and distill off the solvent to obtain the lignin polyoxypropylene ether sulfate product.

[0051] Compared with Example 1, the produ...

Embodiment 3

[0053] A preparation method of lignin polyoxypropylene ether sulfate, comprising the following steps:

[0054] 80g high-boiling alcohol lignin is dissolved in alkaline aqueous solution (pH value 13) to obtain a lignin solution with a concentration of 30%; 35g polypropylene glycol glycidyl ether (molecular weight=200) is dissolved in 80g cyclohexanone to obtain homogeneous solution. Mix the above-mentioned lignin solution and polypropylene glycol glycidyl ether solution together, add 8 g of urea, stir and mix to form a homogeneous semi-water-based system. Then add p-toluenesulfonic acid aqueous solution to adjust the pH of the reaction solution to 5, and keep the reaction at 80°C for 3 hours; then add 10g of sodium bisulfite, and keep the reaction at 85°C for 4 hours. The pH of the product is adjusted to 8 by adding an aqueous sodium hydroxide solution, and the solvent is distilled off to obtain a lignin polyoxypropylene ether sulfate product.

[0055] Compared with Example 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com