High-starch-filled full-biodegradable film and preparation method thereof

A degradable film and whole biological technology, which is applied in the field of high starch-filled fully biodegradable film and its preparation, can solve problems such as the reduction of mechanical properties of materials, and achieve the effects of improved mechanical properties, simplified processing technology and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

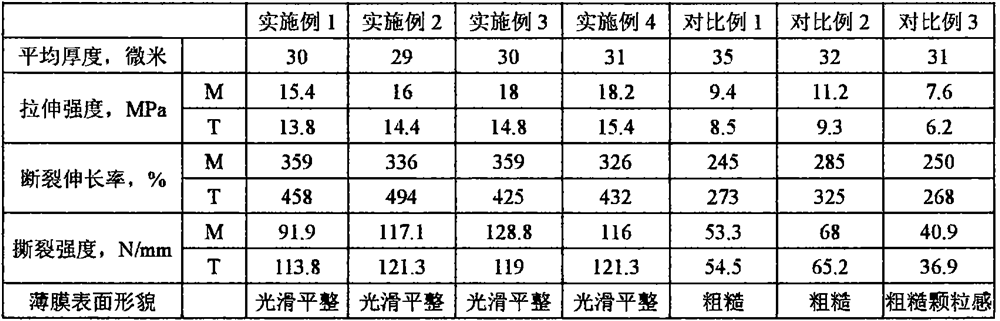

Examples

Embodiment 1

[0025] Weigh 11.3% glycerin according to the weight ratio, add 1.5% N-methylolacrylamide, 1.3% glycidyl methacrylate, and mechanically stir for 30 minutes until the powder is completely dissolved to obtain a glycerin mixture. Add 45% starch, 5% talcum powder, 0.3% antioxidant 1010, 0.1% antioxidant 168, 0.3% antihydrolysis polycarbodiimide, 0.2% opening agent oleic acid amide into the high-speed mixer, add glycerin The mixed solution was slowly added from the top feeding port of the high-speed mixer and mixed for 5 minutes, and finally 35% polyadipate / butylene terephthalate was added and mixed for 2 minutes. Mix and granulate through a twin-screw extruder, and set the maximum temperature in the screw from the feed to the die head to be 100°C in the first zone, 160°C in the second zone, and 150°C in the third zone. The film is blown by a single-screw film blowing machine to obtain a film with a thickness of 30±3 microns, and the maximum temperature in the screw is set at 165°C....

Embodiment 2

[0027] Weigh 10% glycerin according to the weight ratio, add 0.5% N-methylolacrylamide and 1% glycidyl methacrylate, and stir mechanically for 30 minutes until the powder is completely dissolved to obtain a glycerin mixture. Add 44% starch, 3% talcum powder, 0.3% antioxidant 1010, 0.1% antioxidant 168, 0.3% antihydrolysis polycarbodiimide, 0.8% opening agent oleic acid amide into the high-speed mixer, add glycerin The mixed solution was slowly added from the top feeding port of the high-speed mixer and mixed for 5 minutes, and finally 44% polyadipate / butylene terephthalate was added and mixed for 2 minutes. Mix and granulate through a twin-screw extruder, and set the maximum temperature in the screw from the feed to the die head to be 110°C in the first zone, 160°C in the second zone, and 150°C in the third zone. The film is blown by a single-screw film blowing machine to obtain a film with a thickness of 29±3 microns, and the maximum temperature in the screw is set to 170°C. ...

Embodiment 3

[0029] Weigh 10% glycerin according to the weight ratio, add 0.5% N-methylolacrylamide and 0.5% glycidyl methacrylate, and stir mechanically for 30 minutes until the powder is completely dissolved to obtain a glycerin mixture. Add 35% starch, 2% talcum powder, 0.3% antioxidant 1010, 0.3% antioxidant 168, 0.6% antihydrolysis polycarbodiimide, 0.8% opening agent oleic acid amide into the high-speed mixer, add glycerin The mixed solution was slowly added from the top feeding port of the high-speed mixer and mixed for 5 minutes, and finally 50% polyadipate / butylene terephthalate was added and mixed for 2 minutes. Mix and granulate through a twin-screw extruder, and set the maximum temperature in the screw from the feed to the die head to be 120°C in the first zone, 160°C in the second zone, and 150°C in the third zone. The film is blown by a single-screw film blowing machine to obtain a film with a thickness of 30±3 microns, and the maximum temperature in the screw is set at 177°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com