High-performance fiber material with high-strength and high-toughness composite performance and preparation method of high-performance fiber material

A high-performance fiber, high-strength and high-toughness technology, applied in the direction of carbon fiber, fiber treatment, fiber type, etc., can solve the problems of not considering the interface toughness, unfavorable interface toughness, interface rigidity, etc., and achieve the suppression of the mechanical properties of the fiber itself. Effects of suppressing adverse effects and improving interfacial bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

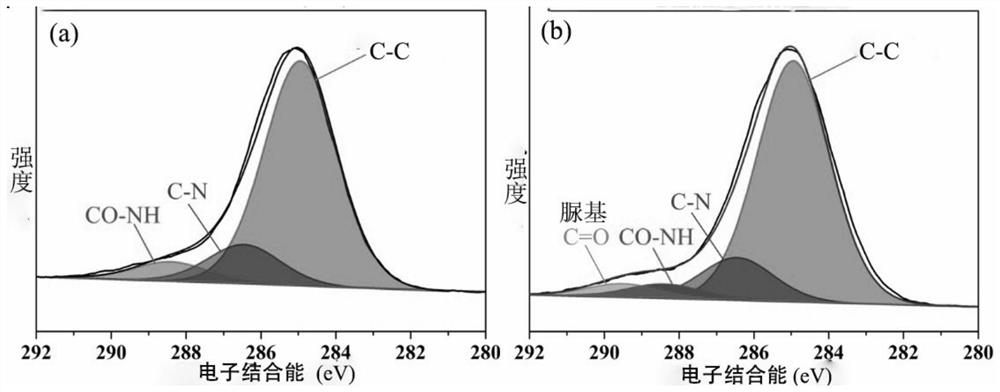

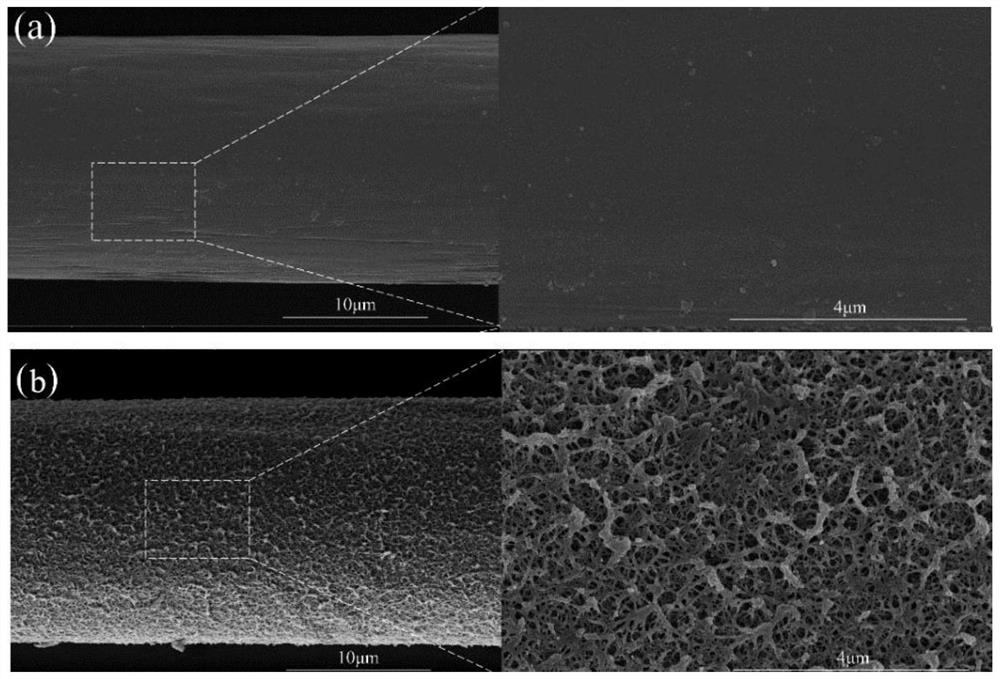

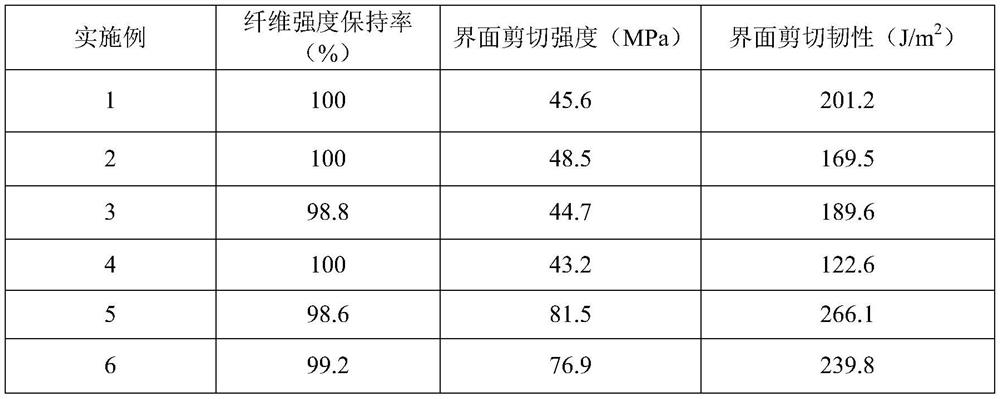

[0029] The aramid II fiber is directly fluorinated by the method disclosed in the prior art under a partial pressure of fluorine gas of 1kPa and a partial pressure of nitrogen gas of 10kPa, and then the fluorinated fiber is placed in a static state dissolved with a mass percentage concentration of 1% In the phenylenediamine acetonitrile solution, react at 30 °C for 30 min and then dry, and then statically soak the aramid II fibers containing amino groups in the acetonitrile of diphenylmethane diisocyanate with a concentration of 2% by mass in acetonitrile at 50 °C. The reaction was carried out for 20 min, followed by washing and drying to obtain aramid II fibers grafted with reactive porous flexible polyurea foam on the surface. The obtained fiber strength retention rate is shown in the attached table.

[0030] The obtained aramid II fiber with high composite performance was added to the epoxy resin matrix to prepare the corresponding composite material, and the interface prop...

Embodiment 2

[0032] First, the aramid II fiber is directly fluorinated by the method disclosed in the prior art under the partial pressure of fluorine gas of 0.5 kPa and the partial pressure of nitrogen gas of 5 kPa, and then the fluorinated fiber is statically soaked in a mass percentage concentration of 2% The phenylenediamine-nitrile solution was soaked and reacted at 50 °C for 60 min and then dried, and then the aramid II fiber was statically soaked in the acetonitrile solution of toluene diisocyanate with a concentration of 1% by mass, reacted at 40 °C for 60 min, and then After washing and drying, the aramid II fibers with reactive porous soft polyurea foam grafted on the surface can be obtained. The obtained fiber strength retention rate is shown in the attached table.

[0033] The obtained high-composite aramid II fiber was added to the phenolic resin system to prepare the corresponding composite material, and the interface properties of the composite material are shown in the atta...

Embodiment 3

[0035] The aramid II fabric (cloth) is directly fluorinated by the method disclosed in the prior art under a fluorine partial pressure of 5kPa and a nitrogen partial pressure of 50kPa, and then the fluorinated fiber is placed in a static state with a mass percentage concentration of dissolved In the acetonitrile solution of 5% m-phenylenediamine, react at 20 °C for 10 minutes and then dry, and then statically soak the aramid II fibers containing amino groups on the surface in 1,6-hexamethylene diisocyanate trimer with a concentration of 5% by mass. In the acetonitrile solution, the reaction was carried out at 80 °C for 5 min, followed by washing and drying to obtain the aramid II fiber grafted with reactive porous flexible polyurea foam on the surface. The obtained fiber strength retention rate is shown in the attached table.

[0036] The obtained aramid II fiber with high composite performance was added to the epoxy resin matrix to prepare the corresponding composite material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com