A flexible conductive paper loaded with silver nanowires and its preparation method and application

A flexible conductive paper and silver nanowire technology, applied in the field of sensing materials, can solve the problems of not being able to make full use of excellent performance, waste of resources, and not being able to give full play to economic value, and achieve degradable biocompatibility and fast paper forming speed , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

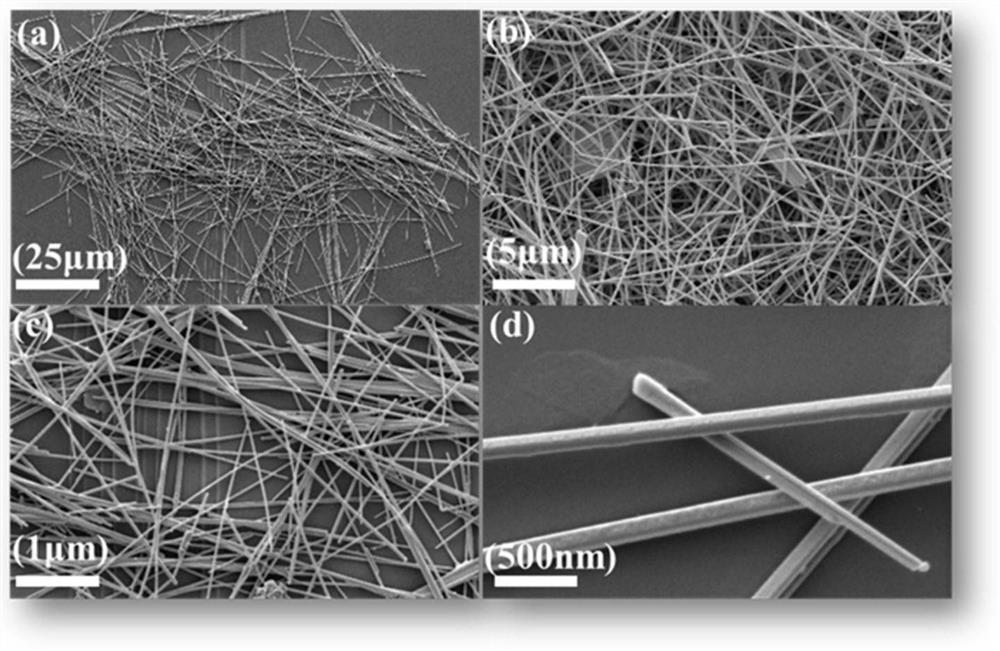

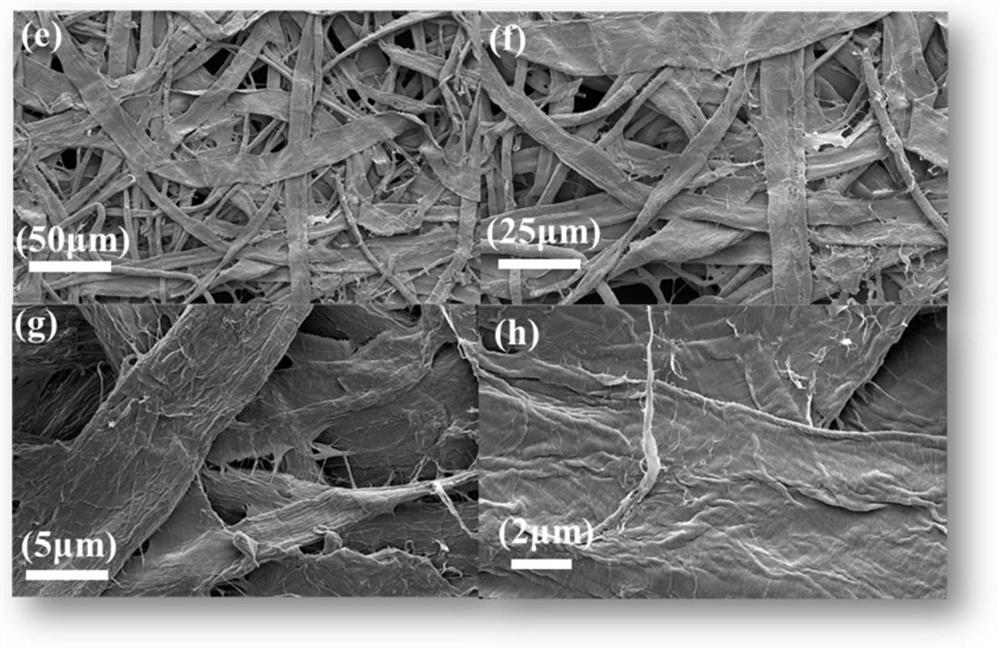

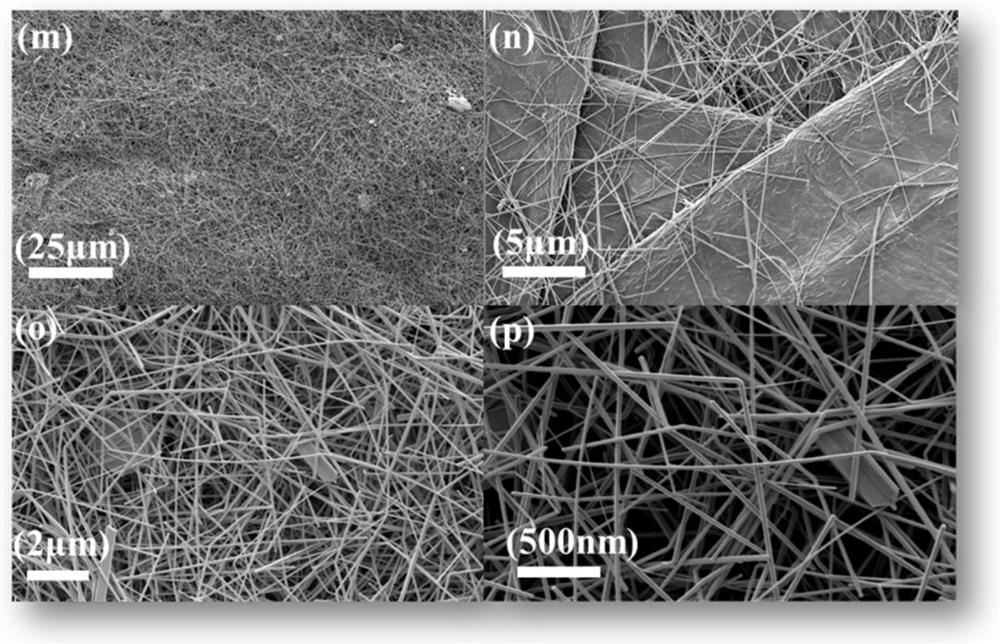

[0054] (1) Synthesis of silver nanowires (AgNWs): Accurately weigh 0.0162 g of ferric chloride hexahydrate crystals (FeCl 3 ·6H 2 O) put it in a beaker, slowly add ethylene glycol (EG) to the total mass of the solution to be 100g (FeCl 3 The concentration of the solution is 550 μM), stir the liquid with a glass rod while adding, and prepare FeCl 3 Salt solution, for use; 0.2g of copper polyvinylpyrrolidine (PVP, Mw=44000~54000) was added to a beaker containing 25ml of ethylene glycol, and magnetically stirred in a 60°C water bath until fully dissolved, Cooled to room temperature to obtain a PVP solution; then 0.2 g of silver nitrate (AgNO 3 ) crystals were added to the PVP solution, stirred rapidly until a transparent and homogeneous solution was formed; finally 3.5 g FeCl was added 3 Salt solution (PVP:AgNO 3 : FeCl 3 =19:5600:10 (material ratio), stir for 1 to 2 minutes, immediately transfer it to a reaction kettle preheated to 125°C, and react for 3 hours. After cooli...

Embodiment 2

[0058] (1) Synthesis of silver nanowires: Accurately weigh 0.0162 g of ferric chloride hexahydrate crystals (FeCl) with a balance 3 ·6H 2 O) put it in a beaker, slowly add ethylene glycol (EG) to the total mass of the solution to be 100g (FeCl 3 The concentration of the solution is 600 μM), stir the liquid with a glass rod while adding, and prepare FeCl 3 Salt solution, for use; 0.2g of copper polyvinylpyrrolidine (PVP, Mw=44000~54000) was added to a beaker containing 25ml of ethylene glycol, and magnetically stirred in a 60°C water bath until fully dissolved, Cooled to room temperature to obtain a PVP solution; then 0.25 g of silver nitrate (AgNO 3 ) crystals were added to the PVP solution, stirred rapidly until a transparent and homogeneous solution was formed; finally 3.5 g FeCl was added 3 Salt solution (PVP:AgNO 3 : FeCl 3 =19:7000:10 (amount of substance ratio)), stir for 1-2 minutes, immediately transfer it to a reaction kettle preheated to 130°C, and react for 4 h...

Embodiment 3

[0062] (1) Synthesis of silver nanowires: Accurately weigh 0.0162 g of ferric chloride hexahydrate crystals (FeCl) with a balance 3 ·6H 2 O) put it in a beaker, slowly add ethylene glycol (EG) to the total mass of the solution to be 100g (FeCl 3 The concentration of the solution is 600 μM), stir the liquid with a glass rod while adding, and prepare FeCl 3 Salt solution, for use; 0.2g of copper polyvinylpyrrolidine (PVP, Mw=44000~54000) was added to a beaker containing 25ml of ethylene glycol, and magnetically stirred in a 60°C water bath until fully dissolved, Cooled to room temperature to obtain a PVP solution; then 0.25 g of silver nitrate (AgNO 3 ) crystals were added to the PVP solution, stirred rapidly until a transparent and homogeneous solution was formed; finally 3.5 g FeCl was added 3 Salt solution (PVP:AgNO 3 : FeCl 3 =19:7000:10 (amount of substance ratio)), stir for 1-2 min, immediately transfer it to a reaction kettle preheated to 130°C, and react for 5 h. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com