Absorbable peripheral stent and preparation method thereof

A prefabricated, end-region technology, applied in the field of medical devices, which can solve the problems of perforation of the blood vessel wall, high patient risk, and fast corrosion rate of local stent rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

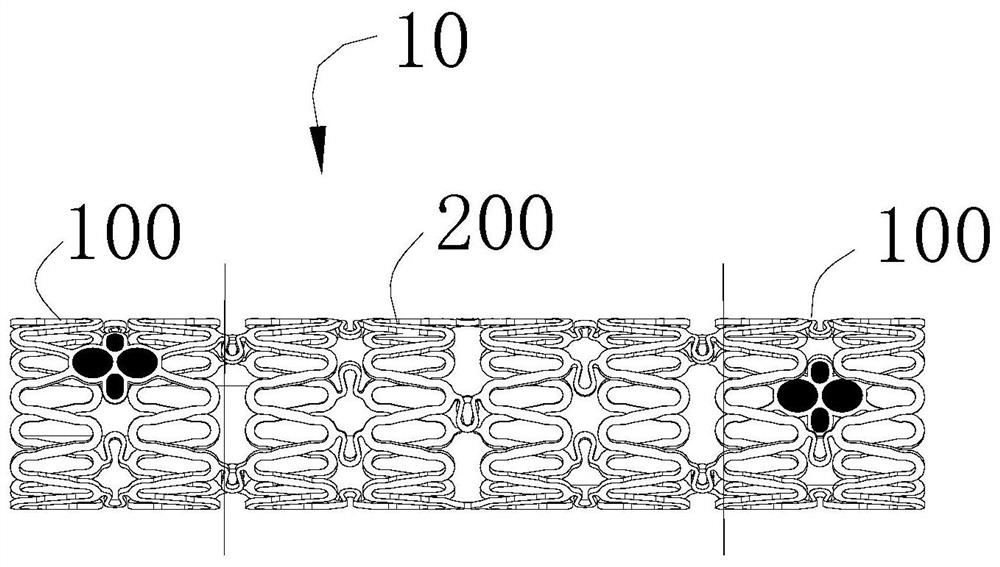

[0048] The present application also provides a method for preparing an absorbable peripheral stent, including providing an absorbable stent preform, and performing nitriding, carburizing, or carbonitriding treatment on the two end regions of the absorbable stent preform, so that The material composition of the end region and the middle region of the treated absorbable stent preform is different, and the material strength of the end region is greater than that of the middle region, and the corrosion rate of the end region is greater than that of the middle region .

[0049] In an embodiment of the present application, the absorbable preform is laser cut from a pure iron (iron content > 99.96wt%) circular tube, and the bracket pattern in the end region is basically consistent with the bracket pattern in the middle region (circumferential The number of upward support rods is the same, and the width and wall thickness of the support rods are basically the same).

[0050] Since th...

Embodiment 1

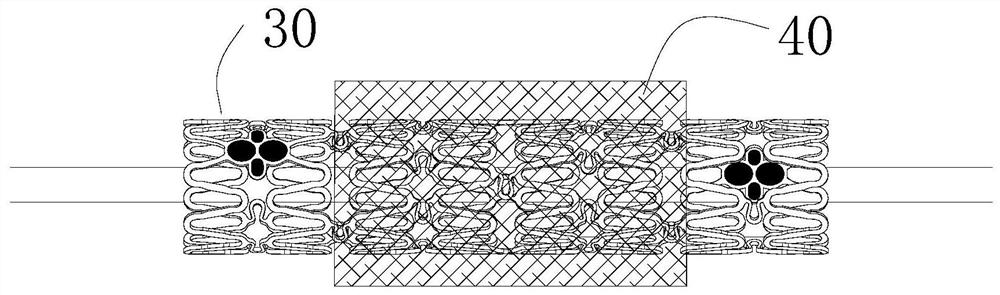

[0062] A pure iron (iron content>99.96wt%) round tube with a wall thickness of about 100 μm is laser cut to form a stent with a symmetrical pattern. After the bracket is initially polished, the outer surface is smooth to form a prefabricated part. The prefabricated part is ion nitriding, the outer surface of the middle area is blocked by a metal ring, and the two end areas are exposed for ion nitriding. The time of ion nitriding is 120 minutes. After the nitriding stent was polished, it was expanded to a nominal diameter with a balloon catheter, and then its properties were measured.

[0063] Using an oxygen, nitrogen and hydrogen analyzer, it is measured that the nitrogen content of the stent rod at the end area is 2000ppm, the Vickers hardness is 357HV, and the in vitro immersion corrosion rate is about 2.0mm / y. The nitrogen content of the stent rod in the middle area is 500ppm, the hardness is 252HV, and the in vitro immersion corrosion rate is about 0.7mm / y.

Embodiment 2

[0065] A pure iron (iron content>99.96wt%) round tube with a wall thickness of about 100 μm is laser cut to form a stent with a symmetrical pattern. After the bracket is initially polished, the outer surface is smooth to form a prefabricated part. The prefabricated part is ion carburized, and the outer surface of the middle area is blocked by a metal ring, and the two end areas are exposed for ion carburizing. The time of ion carburizing is 80 minutes. After the carburized stent was polished, it was expanded to a nominal diameter with a balloon catheter, and then its properties were measured.

[0066] Using scanning electron microscope energy spectrum analysis, it is measured that the carbon content of the support rod in the end region is 1100ppm, the Vickers hardness is 305HV, and the in vitro immersion corrosion rate is about 0.9mm / y. The carbon content of the support rod in the middle area is 500ppm, the Vickers hardness is 219HV, and the in vitro immersion corrosion rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com