Medical disinfection wet tissue capable of promoting wound healing

A technology of wet wipes and cellulose, applied in the field of disinfecting wipes, can solve problems such as poor wound healing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 40mL of 2% sodium hydroxide solution, 1g of cellulose and 3mL of epichlorohydrin into the reactor, stir well and transfer to an oil bath, raise the temperature to 40°C, and place in a nitrogen atmosphere Stir and react at a constant temperature for 4 hours, filter, wash and dry after the reaction to obtain epoxidized cellulose;

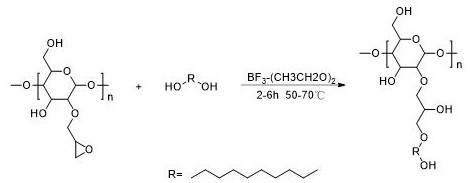

[0029] (2) Add 200mL of deionized water solvent, 1g of epoxidized cellulose and 0.4g of 1,10-decanediol to the reactor, stir until completely dissolved and transfer to the oil bath, continue to add 0.02g of trifluoro Boronium ether complex, after mixing evenly, raise the temperature to 50°C, react for 2 hours, filter, wash and dry after the reaction, to obtain hydroxylated alkyl chain modified cellulose;

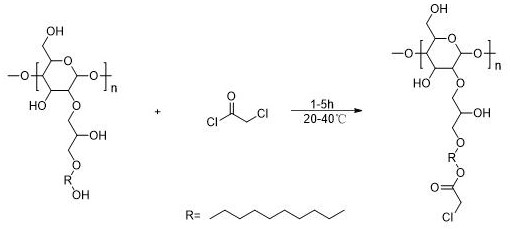

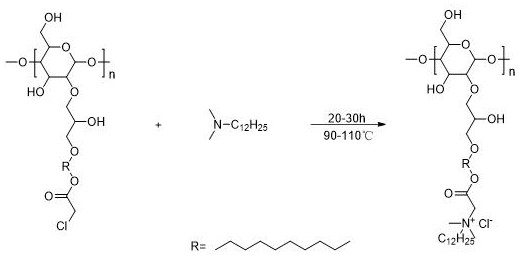

[0030] (3) Add 200mL of ethanol solvent, 1g of hydroxylated alkyl chain modified cellulose and 0.1g of chloroacetyl chloride into the reactor, stir until completely dissolved, transfer to an oil bath, and react for 1h at 20°C under ni...

Embodiment 2

[0034] (1) Add 45mL of 3% sodium hydroxide solution, 1.5g of cellulose and 4mL of epichlorohydrin into the reactor, stir well and transfer to an oil bath, raise the temperature to 45°C, and Stirring and reacting at a medium constant temperature for 5 hours, after the reaction was completed, filtered, washed and dried to obtain epoxidized cellulose;

[0035] (2) Add 350mL of deionized water solvent, 1g of epoxidized cellulose and 0.5g of 1,10-decanediol into the reactor, stir until completely dissolved and transfer to the oil bath, continue to add 0.03g of trifluoro Boronium ether complex, after mixing evenly, raise the temperature to 55°C, react for 3 hours, filter, wash and dry after the reaction, to obtain hydroxylated alkyl chain modified cellulose;

[0036] (3) Add 150mL of ethanol solvent, 1g of hydroxylated alkyl chain modified cellulose and 0.15g of chloroacetyl chloride into the reactor, stir until completely dissolved, transfer to an oil bath, and react for 2h at 25°C...

Embodiment 3

[0040](1) Add 50mL of 4% sodium hydroxide solution, 1.5g of cellulose and 5mL of epichlorohydrin into the reactor, stir well and transfer to an oil bath, raise the temperature to 50°C, and Stir and react at a medium constant temperature for 6 hours, filter, wash and dry after the reaction to obtain epoxidized cellulose;

[0041] (2) Add 650mL of deionized water solvent, 1g of epoxidized cellulose and 0.7g of 1,10-decanediol to the reactor, stir until completely dissolved and transfer to the oil bath, continue to add 0.05g of trifluoro Boronium ether complex, after mixing evenly, raise the temperature to 60°C, react for 5 hours, filter, wash and dry after the reaction, to obtain hydroxylated alkyl chain modified cellulose;

[0042] (3) Add 260mL of ethanol solvent, 1g of hydroxylated alkyl chain modified cellulose and 0.24g of chloroacetyl chloride into the reactor, stir until completely dissolved, transfer to an oil bath, and react at 30°C for 4h under nitrogen protection , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com