Composition, preparation method thereof and light-emitting diode

A technology of light-emitting diodes and compositions, applied in semiconductor/solid-state device manufacturing, applications, inks, etc., can solve the problems of poor film-forming performance of quantum dot inks, reduce uneven film layers, simple operation, and increase luminous efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

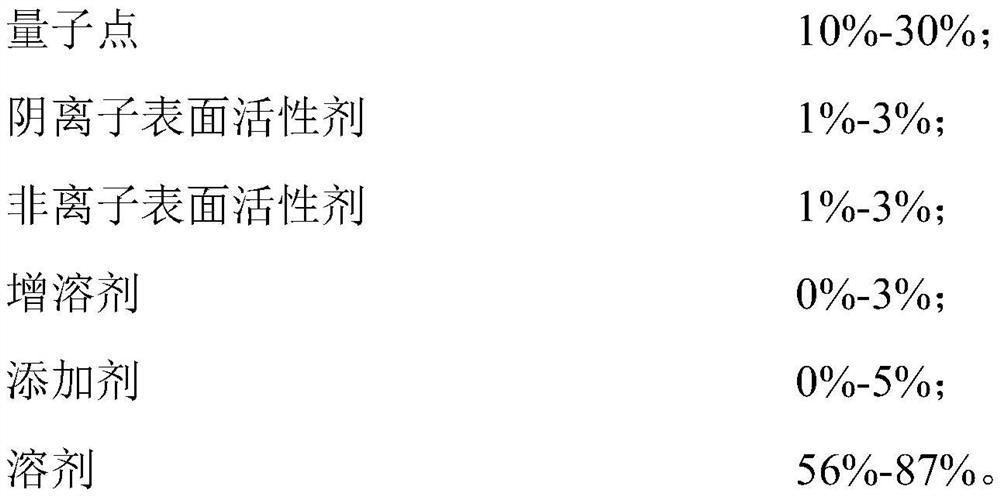

[0028] As an embodiment, the quantum dots include group IV quantum dots, II-VI group quantum dots, II-V group quantum dots, III-V group quantum dots, III-VI group quantum dots, IV-VI group quantum dots, I - At least one of the group III-VI quantum dots, II-IV-VI quantum dots, and II-IV-V group quantum dots, having quantum dot characteristics and high luminous efficiency.

[0029] The above-mentioned quantum dots include but not limited to binary phase, ternary phase, quaternary phase quantum dots, etc., which can be selected as blue quantum dots, green quantum dots, red quantum dots or yellow quantum dots, depending on the actual needs of QLED devices . In some embodiments, the quantum dots are selected as binary phase quantum dots, preferably at least one of CdS, CdSe, CdTe, InP, AgS, PbS, PbSe and HgS. In some embodiments, quantum dots are selected as ternary phase quantum dots, preferably Zn X Cd 1-X S, Cu X In 1-X S, Zn X Cd 1-X Se, Zn X Se 1-X S, Zn X Cd 1-X Te...

Embodiment 1

[0074] This embodiment has prepared a kind of ink and LED:

[0075] (1) Preparation of ink

[0076] The ink raw materials are weighed according to the formula, and the total weight of the ink is 100%, and the ink includes: 10% of green light CdSe quantum dots; 86% of n-hexane; 1% of sodium dodecylbenzenesulfonate; alkanolamide polyoxyethylene Alkylamide 1%; dipropyl ether 1%; triethanolamine monooleate 0.5%; emulsified silicone oil 0.5%.

[0077] Add green light CdSe quantum dots into n-hexane, stir at room temperature for 2 hours to obtain the first solution; then, add remaining raw materials to the first solution, continue stirring until all materials are completely dissolved, filter to obtain ink.

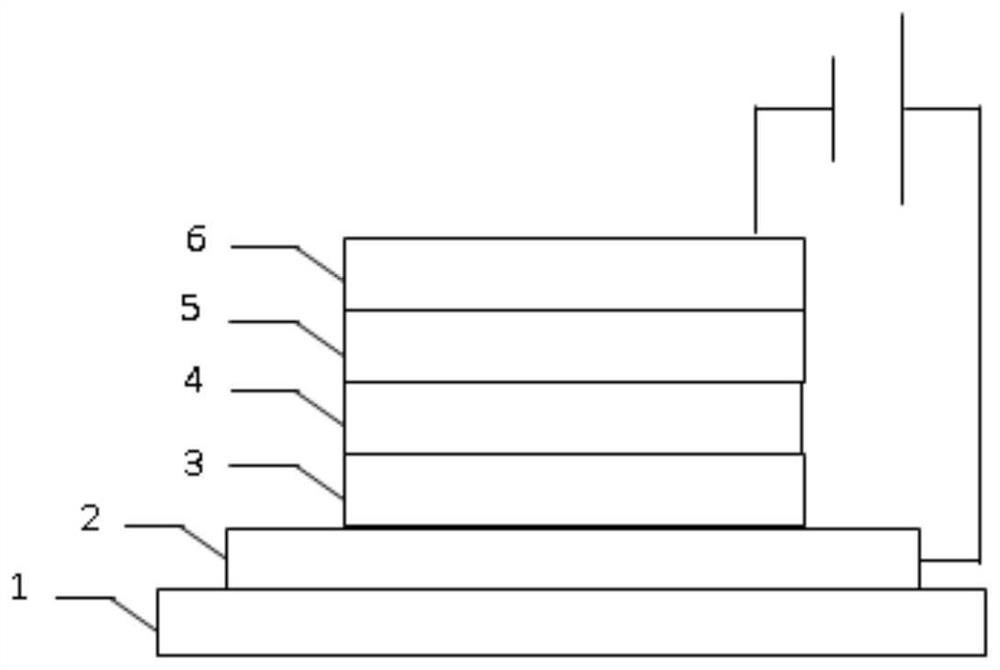

[0078] (2) Preparation of light-emitting diodes

[0079] Provide a substrate, the substrate includes: an anode, a TFB hole transport layer formed on the anode;

[0080] Adopt ink-jet printing method, the ink that step (1) is made is printed on the TFB hole transport layer, dr...

Embodiment 2

[0083] This embodiment has prepared a kind of ink and LED:

[0084] (1) Preparation of ink

[0085] The ink raw materials are weighed according to the formula, based on the total weight of the ink as 100%, the ink includes: red light CdSe quantum dots 20%; cyclooctane 71%; fatty alcohol ether sodium sulfate 3%; pentaerythritol ester 2%; n-hexyl ether 2% ; Triethanolamine monooleate 1%; Higher carbon alcohol 1%.

[0086] Add red CdSe quantum dots into cyclooctane, stir until uniformly dispersed, and obtain the first solution; then, add remaining raw materials into the first solution, continue stirring until all materials are completely dissolved, and filter to obtain ink.

[0087] (2) Preparation of light-emitting diodes

[0088] Provide a substrate, the substrate includes: an anode, a TFB hole transport layer formed on the anode;

[0089] Adopt ink-jet printing method, the ink that step (1) is made is printed on the TFB hole transport layer, dry, form light-emitting layer; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com