Water-based graphene oxide composite anticorrosive paint and preparation method thereof

A technology for anti-corrosion coatings and graphene layers, applied in anti-corrosion coatings, conductive coatings, coatings, etc., can solve the problems of graphene materials such as easy agglomeration, complicated preparation process, and unstable dispersion, so as to improve salt spray resistance, High transparency and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

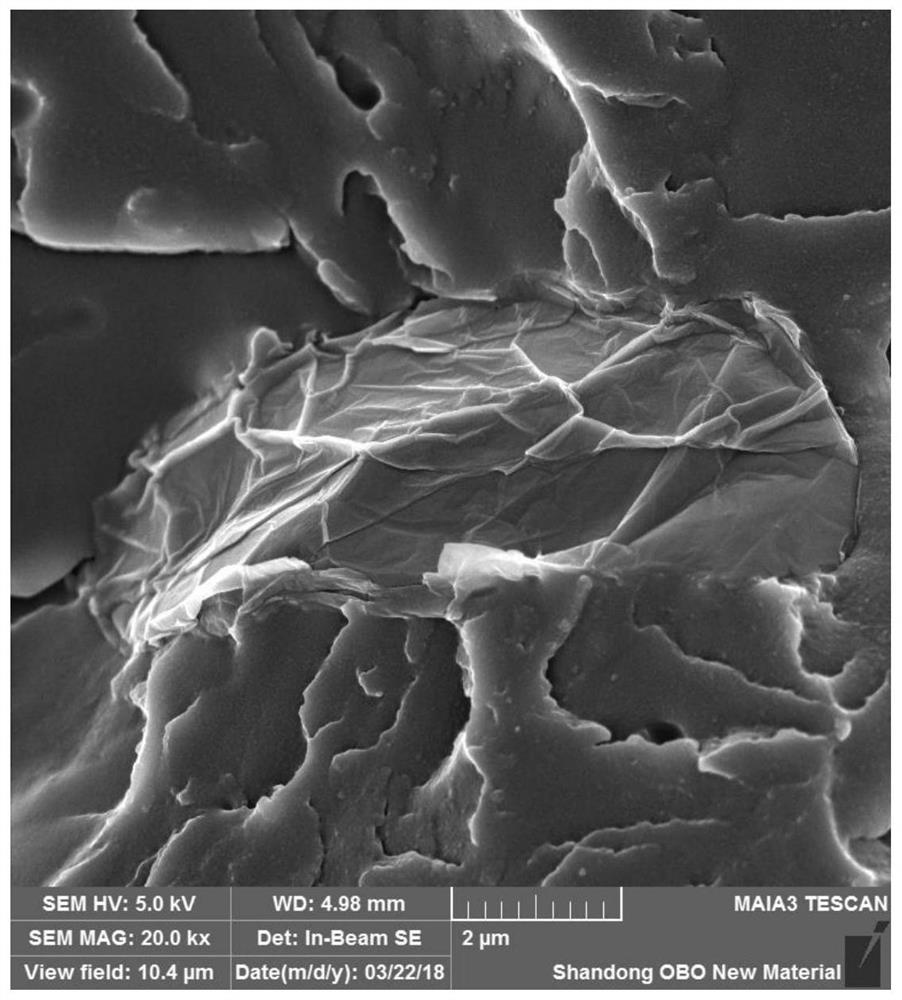

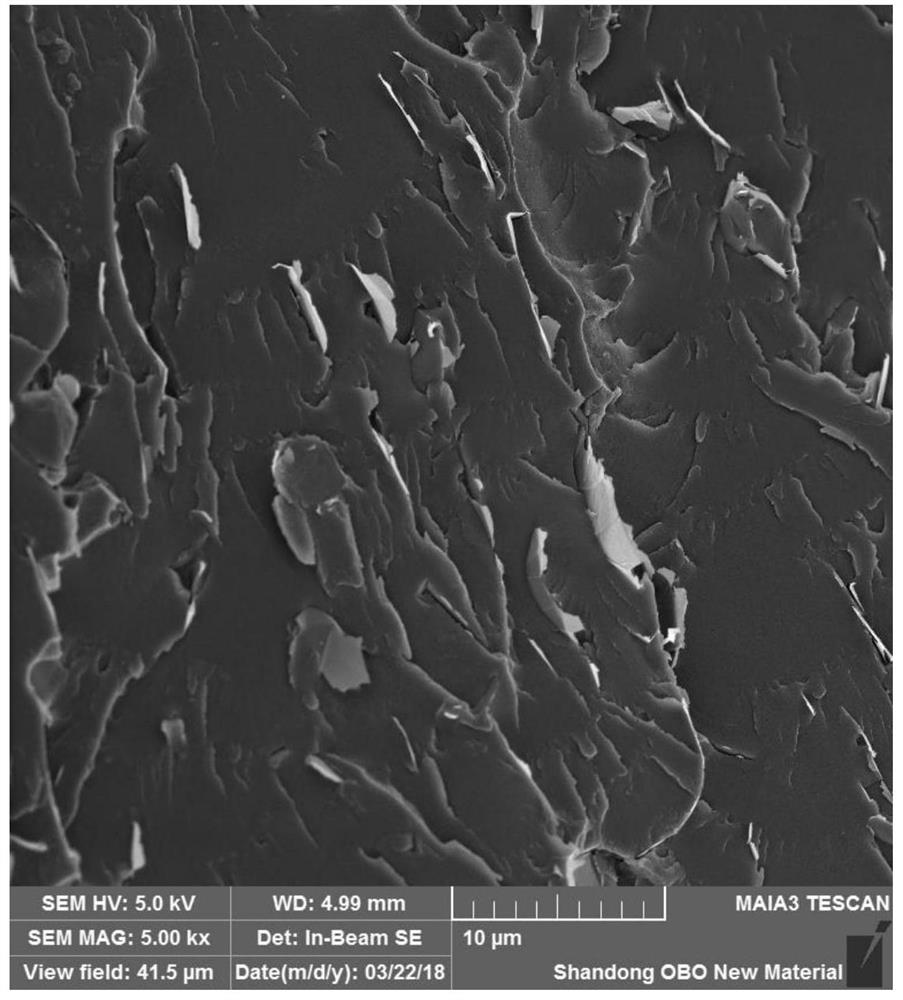

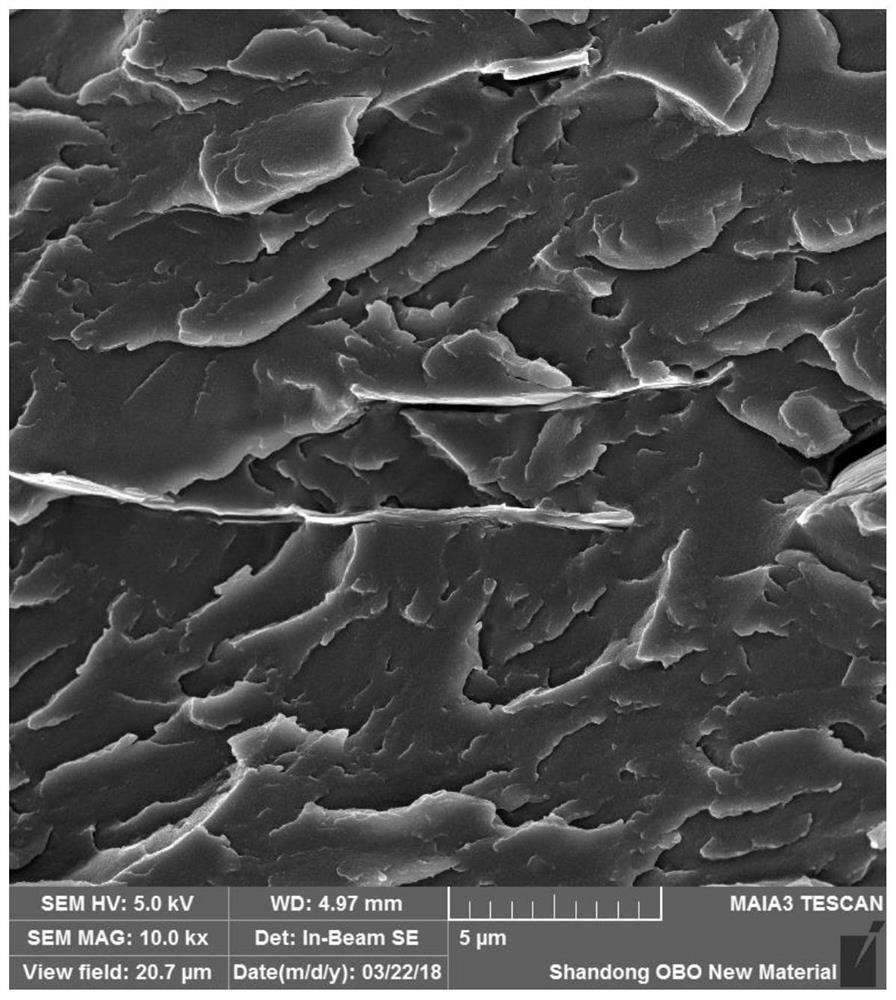

Image

Examples

preparation example Construction

[0117] The present invention also provides a kind of preparation method of graphene oxide acrylic acid emulsion, comprises the following steps:

[0118] 1) After premixing styrene, crosslinking monomer and acrylic polymerizable monomer, mixture A is obtained;

[0119] After the water-based graphene dispersion is heated up, after adding protective colloid and emulsifier for mixing, mixture B is obtained;

[0120] 2) The mixture A and the initiator obtained in the above steps are slowly added to the mixture B, and after the reaction, a graphene oxide acrylic emulsion is obtained.

[0121] The present invention can correspond to the selection and composition of the raw materials required in the above-mentioned preparation process, as well as the corresponding optimization principles, and the selection and composition of the corresponding raw materials in the aforementioned graphene oxide acrylic emulsion, and the corresponding optimization principles. Let me repeat them one by o...

Embodiment 1

[0167] See Table 1, Table 1 is the graphene oxide acrylic emulsion formula table prepared in Examples 1-3 of the present invention.

[0168] Table 1

[0169]

[0170] See Table 2. Table 2 is a list of components of graphene oxide acrylic emulsion prepared in Examples 1-3 of the present invention.

[0171] Table 2

[0172]

[0173] In Examples 1 to 3, the emulsifier is formed by intermixing alkylphenol polyoxyethylene ether sulfate and vinyl ether hydroxyalkylsulfonate with a mass ratio of 1:1.

[0174] The preparation method of the graphene oxide acrylic emulsion provided by table 1 and table 2 may further comprise the steps:

[0175] (1) Mix the ingredients in the first component evenly to obtain solution A;

[0176] (2) Add water-based graphene oxide dispersion liquid into the reaction vessel, heat up to 75-95°C, add protective glue, and ultrasonically stir until dissolved;

[0177] (3) Add an emulsifier to the reaction vessel, and ultrasonically stir until complet...

Embodiment 2

[0182] The preparation method of the graphene oxide acrylic acid emulsion that table 1 provides may further comprise the steps:

[0183] (1) Mix the ingredients in the first component evenly to obtain solution A;

[0184] (2) Add water-based graphene oxide dispersion liquid into the reaction vessel, heat up to 75-95°C, add protective glue, and ultrasonically stir until dissolved;

[0185] (3) Add an emulsifier to the reaction vessel, and ultrasonically stir until completely dissolved;

[0186] (4) Add the solution A and the initiator dropwise to the reaction vessel at the same time, and finish dropping at a constant speed within 2 to 2.5 hours, and keep warm for 30 minutes after dropping;

[0187] (5) Cool down and discharge.

[0188] In step (5), it is preferable to lower the temperature to 70°C first, add tert-butyl hydroperoxide, etc. to remove residual monomers, then lower the temperature, and discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com