Acid liquor system for online acidification of water injection well for oil exploitation and preparation process thereof

A preparation process and technology for water injection wells, which are applied to drilling compositions, chemical instruments and methods, etc., can solve problems such as equipment corrosion, and achieve the effects of reducing damage, improving acidification effect, and expanding acidification range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

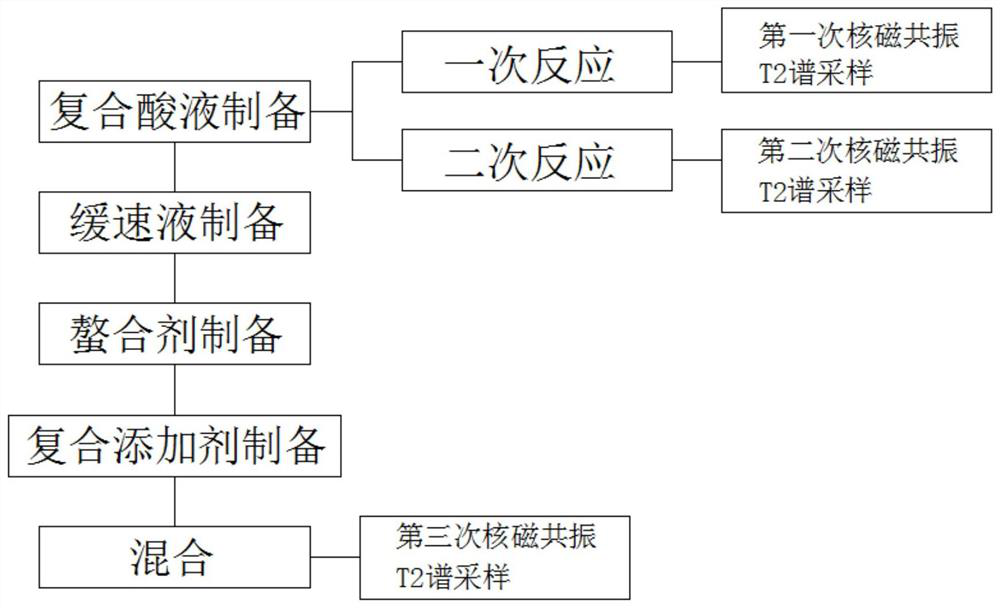

Method used

Image

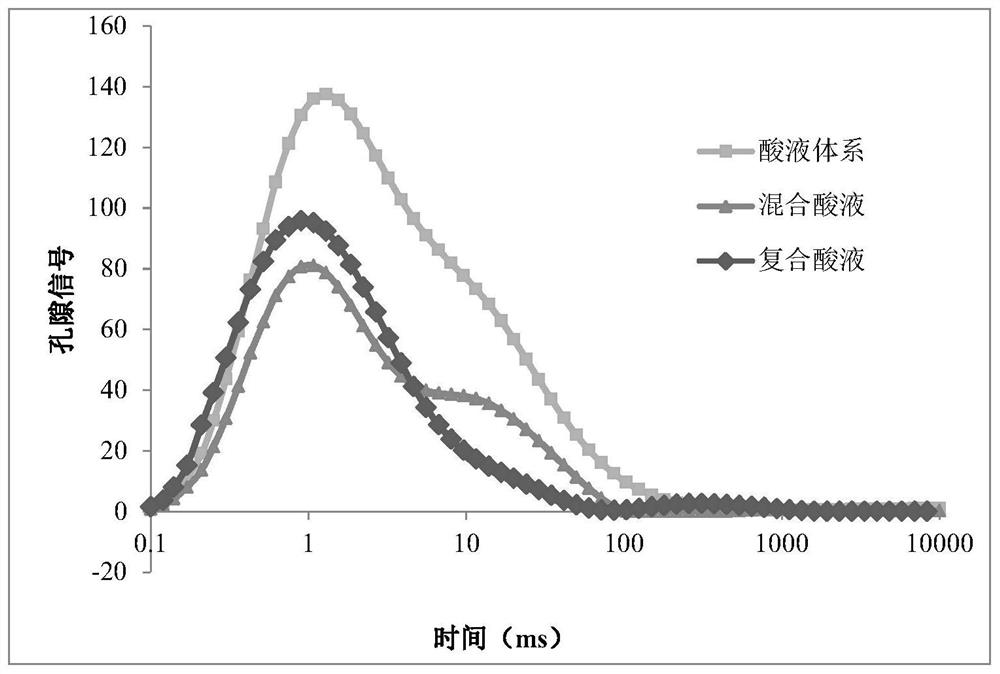

Examples

Embodiment 1

[0036] An acid solution system for on-line acidification of water injection wells for petroleum development, comprising 30% by mass of compound acid solution, 10% by mass of retarder, 5% by mass of chelating agent, and 10% by mass of Composite additives, the remaining components are water;

[0037] The compound acid liquid is hydrochloric acid, naphthenic acid, oxalic acid, and organic phosphonic acid prepared according to the mass ratio of 26:2.5:7.5:1 to form an aqueous solution with a concentration of 30% by mass.

[0038] The retarder is prepared from benzaldehyde, pyridinium salt corrosion inhibitor synergist, hydrazine hydrate, absolute ethanol, and bacterial cellulose in a mass ratio of 3:1:2:1:2 to prepare an aqueous solution with a mass percent concentration of 50%.

[0039]The chelating agent is prepared from an aminophosphonic acid ion exchanger, a complex polyhydroxy chelating agent, and a fluorine-containing complex in a mass ratio of 3:2:1 to prepare an aqueous s...

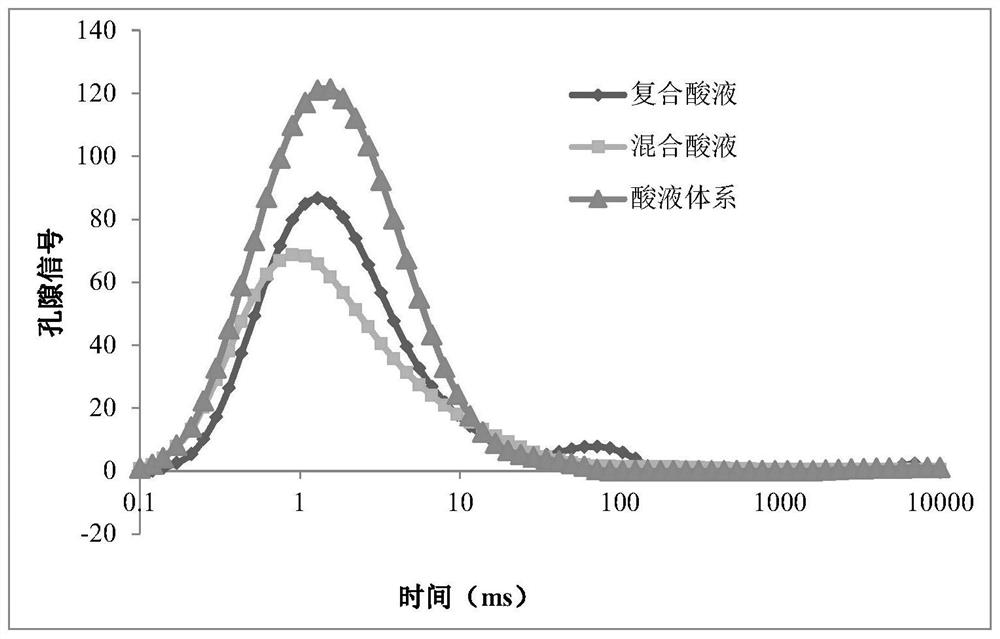

Embodiment 2

[0052] This embodiment is basically the same as Embodiment 1, the difference is that:

[0053] The compound acid solution is compound fluoroboric acid, naphthenic acid, oxalic acid, and organic phosphonic acid according to the mass ratio of 26:2.5:7.5:1 to prepare an aqueous solution with a mass percent concentration of 20%, wherein the compound fluoroboric acid has a mass concentration of 30 % hydrochloric acid and fluoroboric acid with a mass concentration of 23% are composed according to a mass ratio of 1:2.

[0054] S1, preparation of compound acid solution:

[0055] S11. Primary reaction: put 40% of the total amount of the composite fluoroboric acid into the first reaction kettle, adjust the temperature to 40°C, add naphthenic acid dropwise into the first reaction kettle, and continue stirring at a stirring speed of 150r / min , continue to stir and react for 30 minutes after the dropwise addition, to obtain a mixed acid solution;

[0056] S12. Secondary reaction: put 60%...

Embodiment 3

[0062] This embodiment is basically the same as Embodiment 2, the difference is:

[0063] The compound acid solution is compound fluoroboric acid, naphthenic acid, oxalic acid, and organic phosphonic acid according to the mass ratio of 26:2.5:7.5:1 to prepare an aqueous solution with a mass percent concentration of 20%, wherein the compound fluoroboric acid has a mass concentration of 40 % hydrochloric acid and fluoroboric acid with a mass concentration of 30% are composed according to a mass ratio of 1:2.

[0064] S1, preparation of compound acid solution:

[0065] S11. Primary reaction: put 40% of the total amount of the composite fluoroboric acid into the first reaction kettle, adjust the temperature to 32°C, add naphthenic acid dropwise into the first reaction kettle, and continue stirring at a stirring speed of 67r / min , continue to stir and react for 30 minutes after the dropwise addition, to obtain a mixed acid solution;

[0066] S12. Secondary reaction: put 60% of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com