Novel preparation process of BT22 titanium alloy

A preparation process, titanium alloy technology, applied in the field of new preparation process of BT22 titanium alloy, can solve the problems of parts scrapping, cracking, economic loss, etc., and achieve the effect of low cost, low process requirements and low economic risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

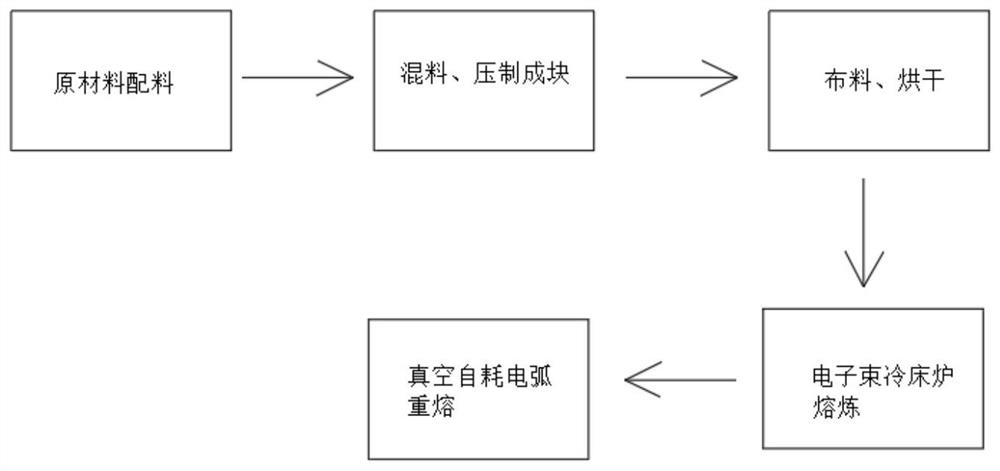

[0053] A novel preparation process for a BT22 titanium alloy, comprising the steps of:

[0054] Step 1: Raw material ingredients:

[0055] The percentages of metal materials required for raw material batching are: sponge titanium 81wt%, aluminum bean 0.9wt%, AlMo70 master alloy 7.65wt%, AlV55 master alloy 8.15wt%, metal chromium 1.4wt% and iron nail 0.9wt%; Take a total of 780kg of raw materials and store them separately;

[0056] Step 2: Mixing and pressing into blocks:

[0057] Add the titanium sponge, AlMo70 master alloy, AlV55 master alloy, metal chromium, iron nails and aluminum beans mentioned in step 1 into the silo of the automatic compounding equipment, after automatic weighing, press in an 80MN hydraulic press to form Material block (titanium lump);

[0058] Step 3: Cloth, Drying:

[0059] Put the block (titanium lump) pressed in step 2 according to 2 pieces in each row, put it into the drying material box in a single layer, and dry the block (titanium lump);

...

Embodiment 2

[0087] A novel preparation process for a BT22 titanium alloy, comprising the steps of:

[0088] Step 1: Raw material ingredients:

[0089] The percentage of metal materials required for raw material batching is: 83wt% of titanium sponge, 0.5wt% of aluminum bean, 6.6wt% of AlMo70 master alloy, 8.05wt% of AlV55 master alloy, 1.2wt% of metal chromium and 0.65wt% of iron nail; Take a total of 780kg of raw materials and store them separately;

[0090] Step 2: Mixing and pressing into blocks:

[0091] Add the titanium sponge, AlMo70 master alloy, AlV55 master alloy, metal chromium, iron nails and aluminum beans mentioned in step 1 into the silo of the automatic compounding equipment, after automatic weighing, press in an 80MN hydraulic press to form Material block (titanium lump);

[0092] Step 3: Cloth, Drying:

[0093] Put the block (titanium lump) pressed in step 2 according to 2 pieces in each row, put it into the drying material box in a single layer, and dry the block (tit...

Embodiment 3

[0121] A novel preparation process for a BT22 titanium alloy, comprising the steps of:

[0122] Step 1: Raw material ingredients:

[0123] The percentages of metal materials required for raw material batching are: 82wt% of titanium sponge, 0.6wt% of aluminum beans, 7.2wt% of AlMo70 master alloy, 8.08wt% of AlV55 master alloy, 1.3wt% of metal chromium and 0.82wt% of iron nails; Take a total of 780kg of raw materials and store them separately;

[0124] Step 2: Mixing and pressing into blocks:

[0125] Add the titanium sponge, AlMo70 master alloy, AlV55 master alloy, metal chromium, iron nails and aluminum beans mentioned in step 1 into the silo of the automatic compounding equipment, after automatic weighing, press in an 80MN hydraulic press to form Material block (titanium lump);

[0126] Step 3: Cloth, Drying:

[0127] Put the block (titanium lump) pressed in step 2 according to 2 pieces in each row, put it into the drying material box in a single layer, and dry the block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com