Bismuth antimony telluride/graphene potassium ion battery negative electrode material with high-stability structure and preparation method thereof

A battery negative electrode, bismuth antimony telluride technology, applied to battery electrodes, active material electrodes, negative electrodes, etc., can solve the problems of difficult and limited kinetics and stability, and achieve simple and fast methods, enhance electrical conductivity, and inhibit The effect of volume deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

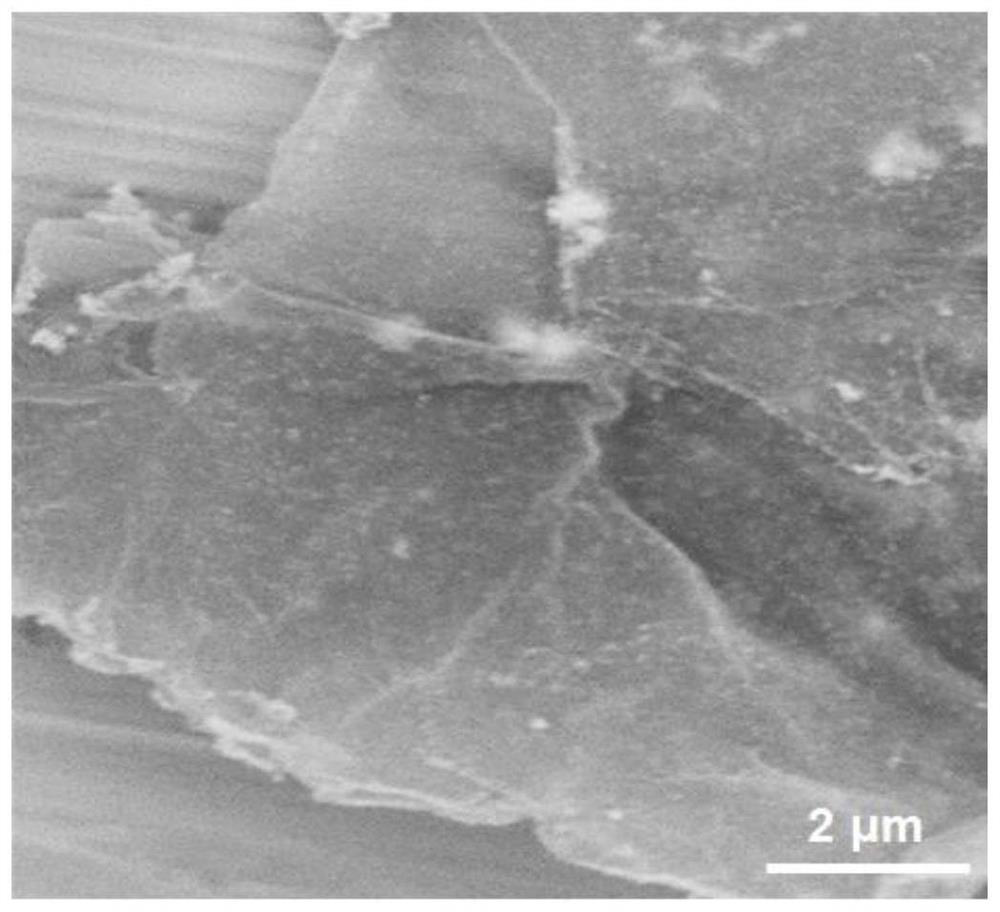

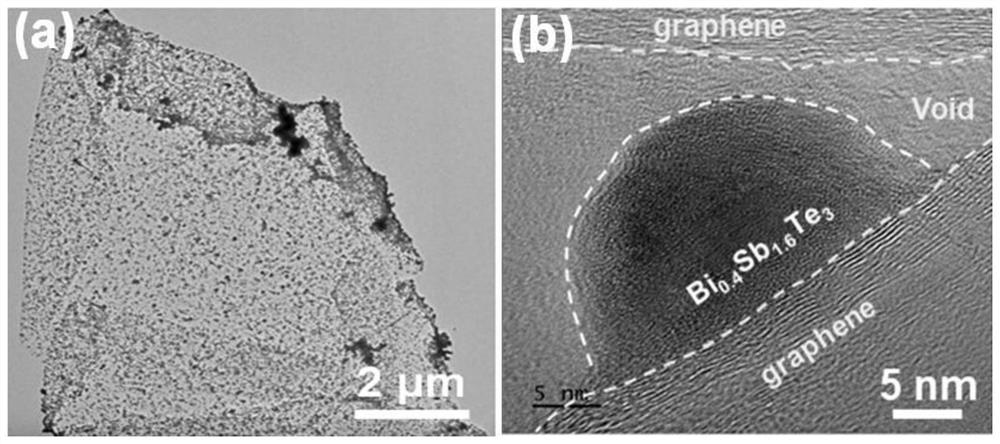

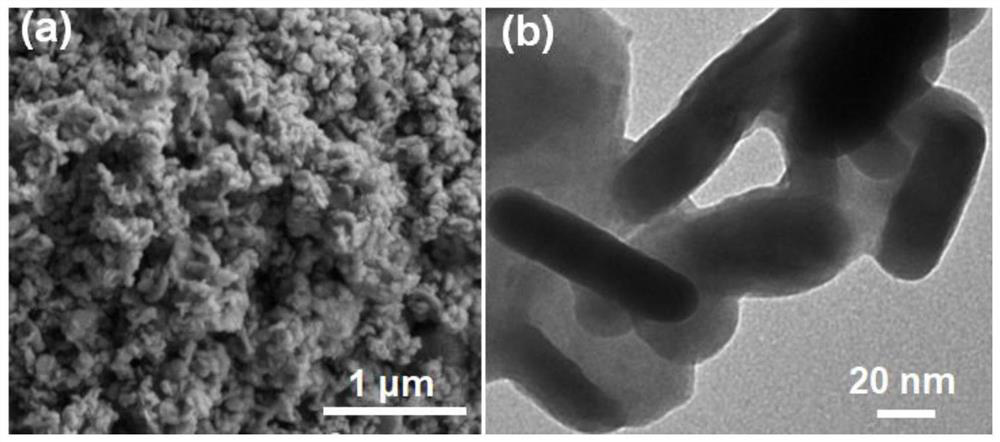

[0028] This embodiment prepares the Bi with high stability structure according to the following steps 0.4 Sb 1.6 Te 3 / Graphene potassium ion battery anode material:

[0029] Step 1. Weigh 6.3mg of BiCl 3 Dissolve in 40 μL concentrated HNO with a mass fraction of 68% 3 In, get BiCl 3 nitric acid solution;

[0030] Weigh 5mL of 2.21mg mL –1 Graphene oxide dispersion and sonicated for 1 h; then added BiCl 3 Nitric acid solution, 18.2 mg of SbCl 3 , 0.4 g of tartaric acid and stirred until dissolved; then added 33 mg of Na 2 TeO 3 , 20mL ammonia water and 8mL hydrazine hydrate and continue stirring for 3h to obtain a mixed reaction solution.

[0031] Step 2. Pour the mixed reaction liquid obtained in step 1 into a reaction kettle, react at 180°C for 5 hours, then collect the reaction precipitate by centrifugation, wash with distilled water and absolute ethanol several times, and dry it in vacuum at 60°C for 24 hours to obtain potassium ions Bi of battery anode materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com