Low-temperature working condition fire extinguishing block

A working condition, low temperature technology, applied in the field of low temperature working condition fire extinguishing block, to achieve the effect of good fire extinguishing performance, excellent insulation, and reducing the possibility of secondary combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

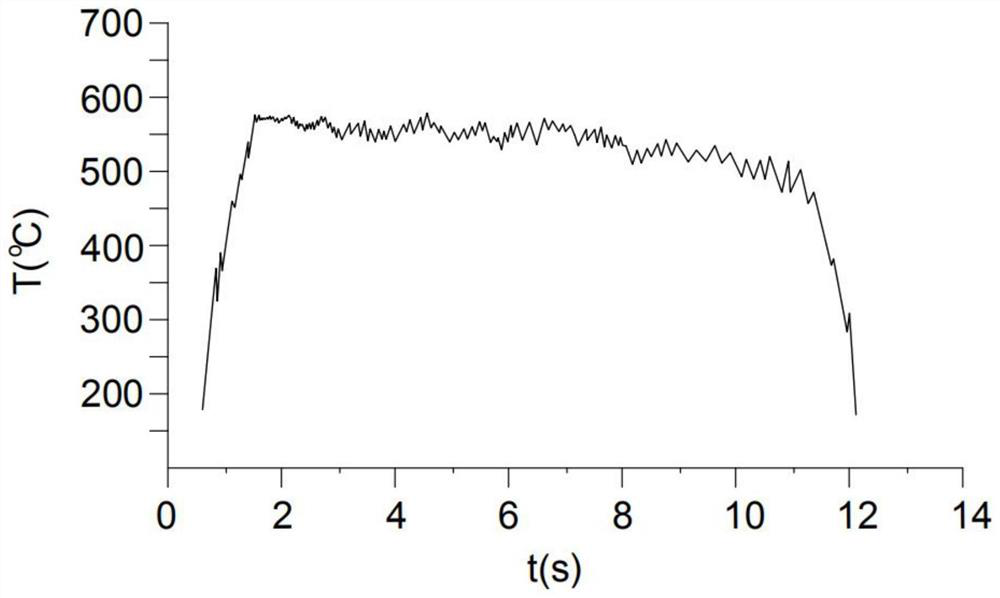

Image

Examples

Embodiment 1

[0038] The fire extinguishing block weighs each component according to the following parts by mass:

[0039]70 parts of calcium perchlorate, 15 parts of dipolycyanamide, 3 parts of hexamethylenetetramine, 4 parts of magnesium oxalate, 1 part of magnesium powder, 3 parts of sodium bicarbonate, 1 part of sodium citrate, 4 parts of polyurethane resin .

[0040] Weigh 15g of the formula described in Example 1, and carry out a fire extinguishing experiment in a test box with a volume of 0.35m3. The fire extinguishing time is 29s, and the fire extinguishing efficiency is 42.86g / m3. Corrosion test was carried out on the combustion products, the weight loss rate of copper sheet was 0.052%, the weight loss rate of aluminum sheet was 0.085%, and the insulation test result was 126MΩ

Embodiment 2

[0042] The fire extinguishing block weighs each component according to the following parts by mass:

[0043] 64 parts of calcium perchlorate, 25 parts of dicyandiamide, 1 part of hexamethylenetetramine, 1 part of magnesium oxalate, 1 part of magnesium powder, 4 parts of sodium bicarbonate, 1 part of sodium citrate, 3 parts of polyurethane resin.

[0044] Take by weighing 15g of the formulation described in Example 2, and carry out a fire extinguishing experiment in a test box with a volume of 0.35m3. The fire extinguishing time is 26s, and the fire extinguishing efficiency is 42.86g / m3. The corrosion test was carried out on the combustion products, the weight loss rate of the copper sheet was 0.013%, the weight loss rate of the aluminum sheet was 0.062%, and the insulation test result was 129MΩ.

Embodiment 3

[0046] The fire extinguishing block weighs each component according to the following parts by mass:

[0047] Calcium perchlorate 65 parts, dipolycyanamide 20 parts, hexamethylenetetramine 4 parts, magnesium oxalate 2 parts, magnesium powder 2 parts, sodium bicarbonate 3 parts, sodium citrate 1 part, polyurethane resin 3 parts.

[0048] Take by weighing 15g of the formulation described in Example 3, and carry out a fire extinguishing experiment in a test box with a volume of 0.35m3. The fire extinguishing time is 33s, and the fire extinguishing efficiency is 42.86g / m3. Corrosion test was carried out on the combustion products, the weight loss rate of copper sheet was 0.076%, the weight loss rate of aluminum sheet was 0.173%, and the insulation test result was 130MΩ

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com