Micro-capsule powder and nutritional composition containing micro-capsule powder and used for promoting milk secretion for wet nurse

A nutritional composition and microencapsulated powder technology, applied in the field of dairy product processing, can solve the problems of emulsifying ability, emulsifying stability, poor film formation, affecting the shelf life of powdered oil, accelerating product oxidation and rancidity, etc., to eliminate insufficient milk secretion anxiety, increase breastfeeding rate, and promote milk secretion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

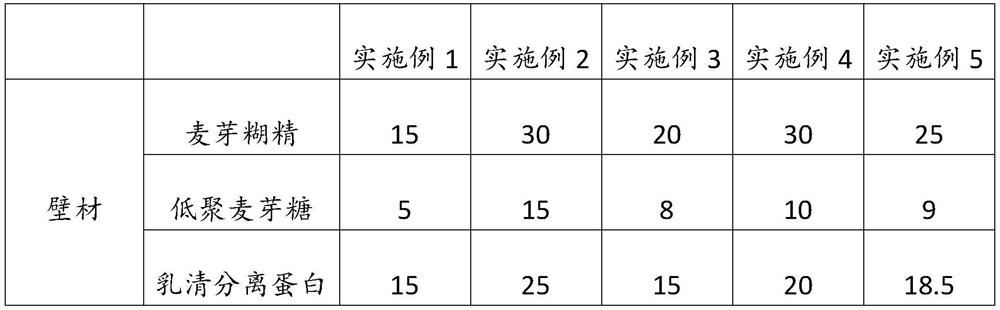

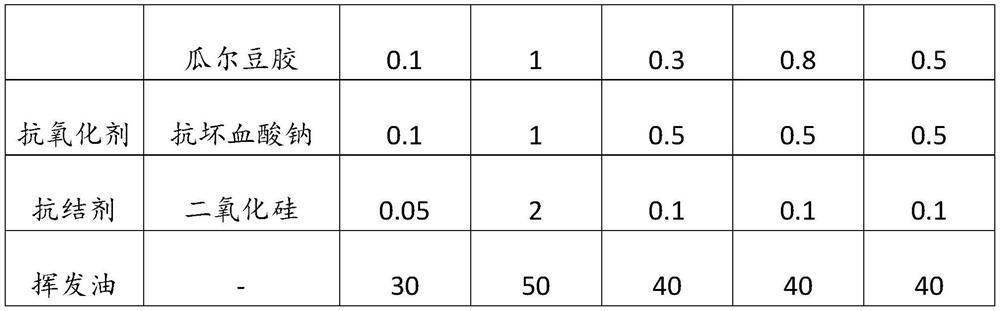

Embodiment 1

[0032] The preparation method of the microcapsule powder described in Example 1 of the present application comprises the following steps:

[0033] (1) Prepare the water phase: add water at 50°C to the wall material, stir to dissolve, and obtain the water phase A;

[0034] (2) Prepare the oil phase: mix the anticaking agent, antioxidant and sunflower oil at 40°C to obtain the oil phase B;

[0035] (3) Mixing and dissolving: add the oil phase B obtained in step (2) to the water phase A obtained in step (1), and stir at 50°C to obtain a mixed solution;

[0036] (4) Pasteurization and emulsification: pasteurize the mixed solution obtained in step (3), and shear emulsification. The speed of shear emulsification is 7000r / min, the temperature of shear emulsification is 60°C, and the time of shear emulsification Be 15min, obtain emulsion;

[0037] (5) Homogenization, spray drying: the emulsion obtained in step (4) is homogenized, the method of homogenization is the combination of ul...

Embodiment 2

[0039] The preparation method of the microcapsule powder described in Example 2 of the present application comprises the following steps:

[0040] (1) Prepare the water phase: add water at 70°C to the wall material, stir to dissolve, and obtain the water phase A;

[0041] (2) Prepare the oil phase: mix the anticaking agent, antioxidant and linseed oil uniformly at 60°C to obtain the oil phase B;

[0042] (3) Mixing and dissolving: add the oil phase B obtained in step (2) to the water phase A obtained in step (1), and stir at 50-70°C to obtain a mixed solution;

[0043] (4) Pasteurization and emulsification: pasteurize the mixed solution obtained in step (3), and shear emulsification. The speed of shear emulsification is 9000r / min, the temperature of shear emulsification is 80°C, and the time of shear emulsification Be 25min, obtain emulsion;

[0044] (5) Homogenization, spray drying: the emulsion obtained in step (4) is homogenized, the method of homogenization is the combinat...

Embodiment 3

[0046] The preparation method of the microcapsule powder described in Example 3 of the present application comprises the following steps:

[0047] (1) Prepare the water phase: add water at 60°C to the wall material, stir to dissolve, and obtain the water phase A;

[0048] (2) Prepare the oil phase: mix the anticaking agent, antioxidant and sunflower oil at 50°C to obtain the oil phase B;

[0049] (3) Mixing and dissolving: add the oil phase B obtained in step (2) to the water phase A obtained in step (1), and stir at 60°C to obtain a mixed solution;

[0050] (4) Pasteurization and emulsification: pasteurize the mixed solution obtained in step (3), and shear emulsification. The speed of shear emulsification is 8000r / min, the temperature of shear emulsification is 70°C, and the time of shear emulsification Be 20min, obtain emulsion;

[0051] (5) Homogenization, spray drying: the emulsion obtained in step (4) is homogenized, the method of homogenization is the combination of ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com