Preparation method of photo-thermal sensitive composite bacterial cellulose antibacterial dressing

A technology of bacterial cellulose and bacterial cellulose film is applied in the field of preparation of photothermal-sensitive composite bacterial cellulose antibacterial dressings, and achieves the effects of lasting antibacterial effect, low cost, excellent biocompatibility and cell affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

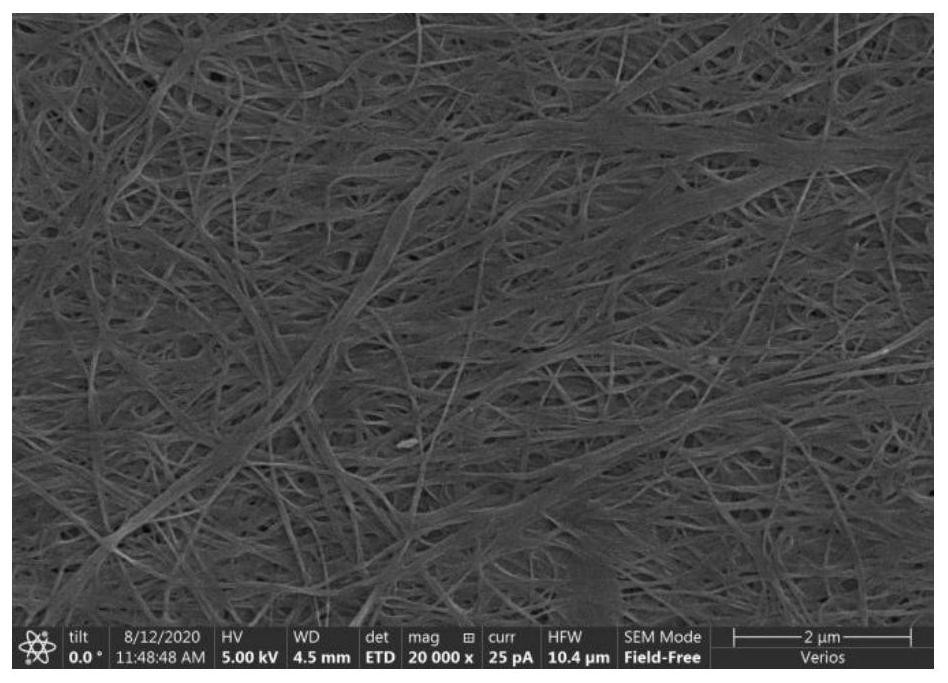

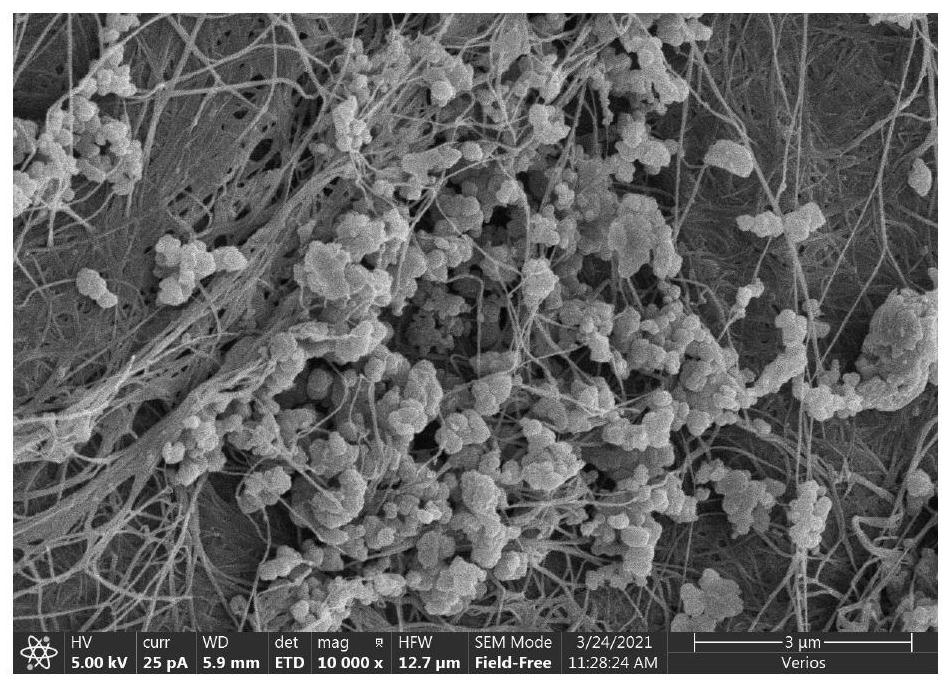

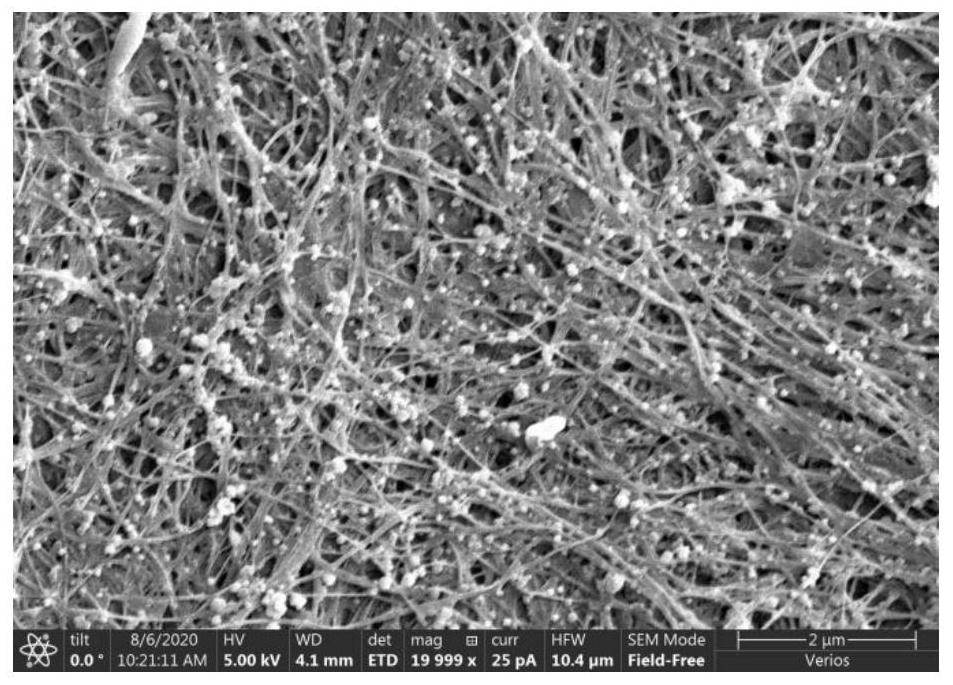

Image

Examples

Embodiment 1

[0037] The preparation method of photothermal sensitive composite bacterial cellulose antibacterial dressing, specifically comprises the following steps:

[0038] (1) Take bacterial cellulose with a thickness of 0.2cm, wash the surface with water to remove surface impurities, then rinse with deionized water for 3 times, soak in deionized water for 5h, and then use a NaOH aqueous solution with a concentration of 0.1mol / L at 85°C Heat and boil in a water bath for 1 hour to remove the endotoxin in the bacterial cellulose, take it out, rinse it with deionized water for 3 times, and then soak it in deionized water for 5 times to obtain the bacterial cellulose film, and refrigerate at 4°C for later use;

[0039] (2) Get 15 mL of 0.1 mol / L hydrochloric acid solution and mix 50 mL of 0.1 mol / L Tris solution, dilute to 100 mL to obtain Tris-HCl buffer solution, add 0.124 g of dopamine hydrochloride to obtain a dopamine buffer solution with a concentration of 1.0 mg / mL, Then add the bacte...

Embodiment 2

[0045] The preparation method of photothermal sensitive composite bacterial cellulose antibacterial dressing, specifically comprises the following steps:

[0046] (1) Take bacterial cellulose with a thickness of 0.2cm, wash the surface with water to remove surface impurities, then rinse twice with deionized water, soak in deionized water for 3h, and then use a NaOH aqueous solution with a concentration of 0.1mol / L at 80°C Heated and boiled in a water bath for 1 hour to remove endotoxin in the bacterial cellulose, rinsed twice with deionized water after taking it out, and then soaked in deionized water for 3 times to obtain bacterial cellulose membrane, refrigerated at 4°C for later use;

[0047] (2) Get 15 mL of 0.1 mol / L hydrochloric acid solution and mix 50 mL of 0.1 mol / L Tris solution, dilute to 100 mL to obtain Tris-HCl buffer solution, add 0.62 g of dopamine hydrochloride to obtain a dopamine buffer solution with a concentration of 0.5 mg / mL, Then add the bacterial cellu...

Embodiment 3

[0050] The preparation method of photothermal sensitive composite bacterial cellulose antibacterial dressing, specifically comprises the following steps:

[0051] (1) Take bacterial cellulose with a thickness of 0.2 cm, wash the surface with water to remove surface impurities, then rinse with deionized water for 3 times, soak in deionized water for 5 hours, and then use a NaOH aqueous solution with a concentration of 0.1mol / L at 90°C Heat and boil in a water bath for 1 hour to remove the endotoxin in the bacterial cellulose, take it out, rinse it with deionized water for 3 times, and then soak it in deionized water for 5 times to obtain the bacterial cellulose film, and refrigerate at 4°C for later use;

[0052] (2) Get 15 mL of 0.1 mol / L hydrochloric acid solution and 50 mL of 0.1 mol / L Tris solution and mix, dilute to 100 mL to obtain Tris-HCl buffer solution, add 0.248 g of dopamine hydrochloride to obtain a dopamine buffer solution with a concentration of 2.0 mg / mL, Then a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com