High-permeability anti-fouling nanofiber separation membrane material and preparation method and application thereof

A nanofiber and high-permeability technology, applied in the field of membrane separation, can solve the problems of polyethersulfone selective layer falling off easily, low membrane pore uniformity, and reduced filtration efficiency, achieving strong design and operability, Improves permeability and stain resistance, and prolongs service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of a high-permeability antifouling nanofiber separation membrane material, comprising the following steps:

[0037] S1. Disperse the polymer nanofibers in a mixed solvent of an organic solvent and deionized water, then add a predetermined amount of a chemical crosslinking agent, stir evenly to obtain a nanofiber suspension, and keep it sealed for later use;

[0038] S2. Applying the nanofiber suspension obtained in step S1 to the surface of the fabric substrate by wet non-woven technology, and drying at room temperature to obtain a highly permeable antifouling nanofiber separation membrane material.

[0039] In step S1, in the mixed solvent, the mass ratio of the organic solvent to deionized water is 1:1; the organic solvent is one of ethanol, acetic acid, isopropanol, acetone, and dimethylformamide The addition amount of the chemical crosslinking agent accounts for 0.1-3.0 wt% of the mass of the polymer nanofiber...

Embodiment 1

[0044] This example provides a high-permeability antifouling nanofiber separation membrane material and its preparation method.

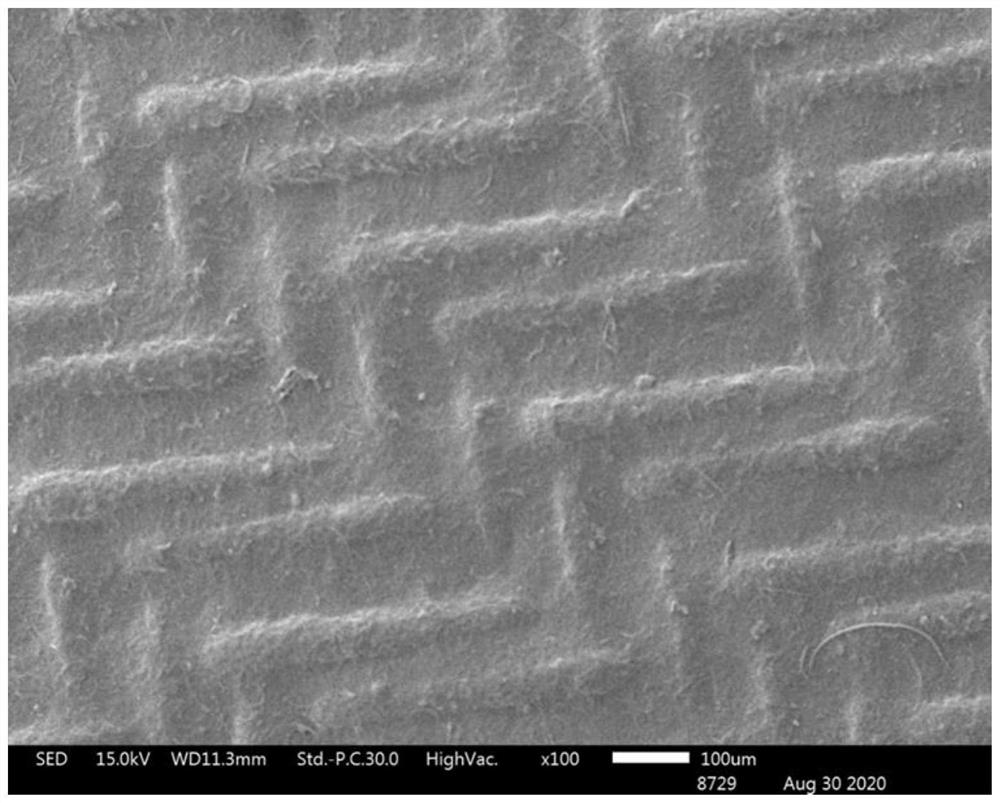

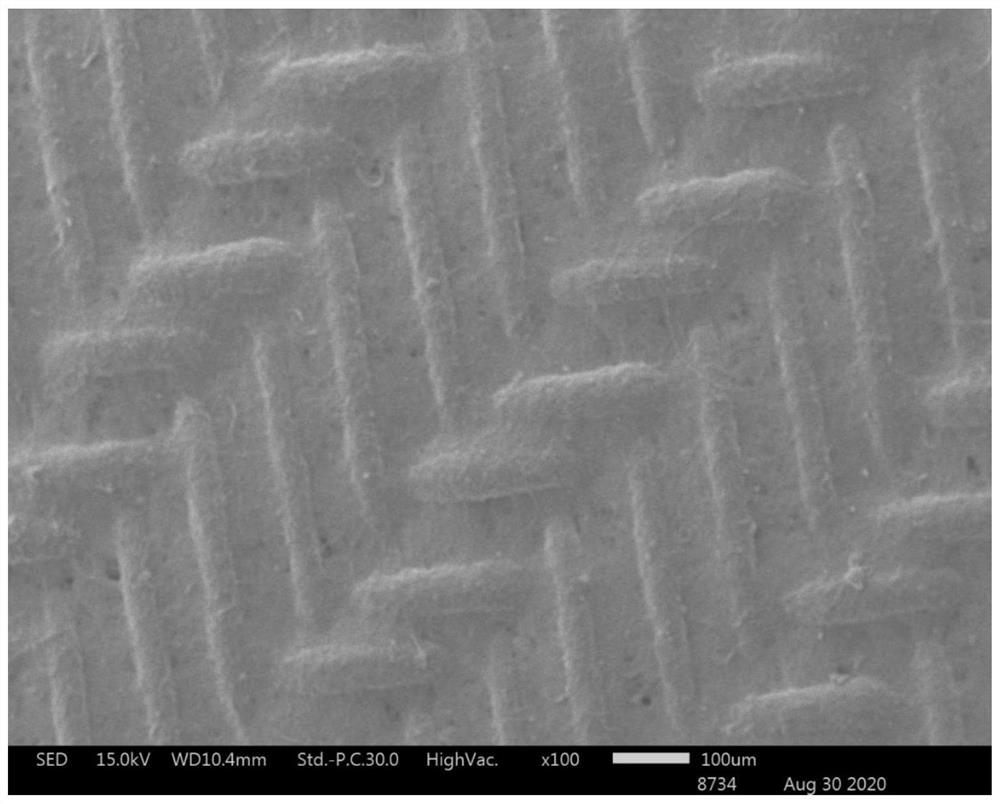

[0045] The separation membrane material comprises a fabric base material and a polymer nanofiber coating loaded on the surface of the fabric base material, and the fabric base material and the polymer nanofiber coating are closely bonded by a chemical crosslinking agent. Wherein, the fabric substrate is a woven fabric with a surface periodic texture structure, and the polymer nanofiber coating is prepared by a wet non-woven process, and has the same surface periodic texture structure as the fabric substrate.

[0046] Specifically, the preparation method of the separation membrane material comprises the following steps:

[0047] S1. Disperse the ethylene vinyl alcohol copolymer nanofibers prepared by the electrospinning method in a mixed solvent with a mass ratio of ethanol and deionized water of 1:1, and then add a chemical crosslinking agent ammoni...

Embodiment 2~7

[0053] Embodiments 2 to 7 respectively provide a method for preparing a high-permeability anti-fouling nanofiber separation membrane material. Compared with Example 1, the difference is that the types of raw materials and process parameters used in step S1 are changed. Specifically The types of raw materials and corresponding process parameters are shown in Table 1, and the rest of the parameters are consistent with those in Example 1, and will not be repeated here.

[0054] Table 1 embodiment 2~7 in the process condition in step S1

[0055]

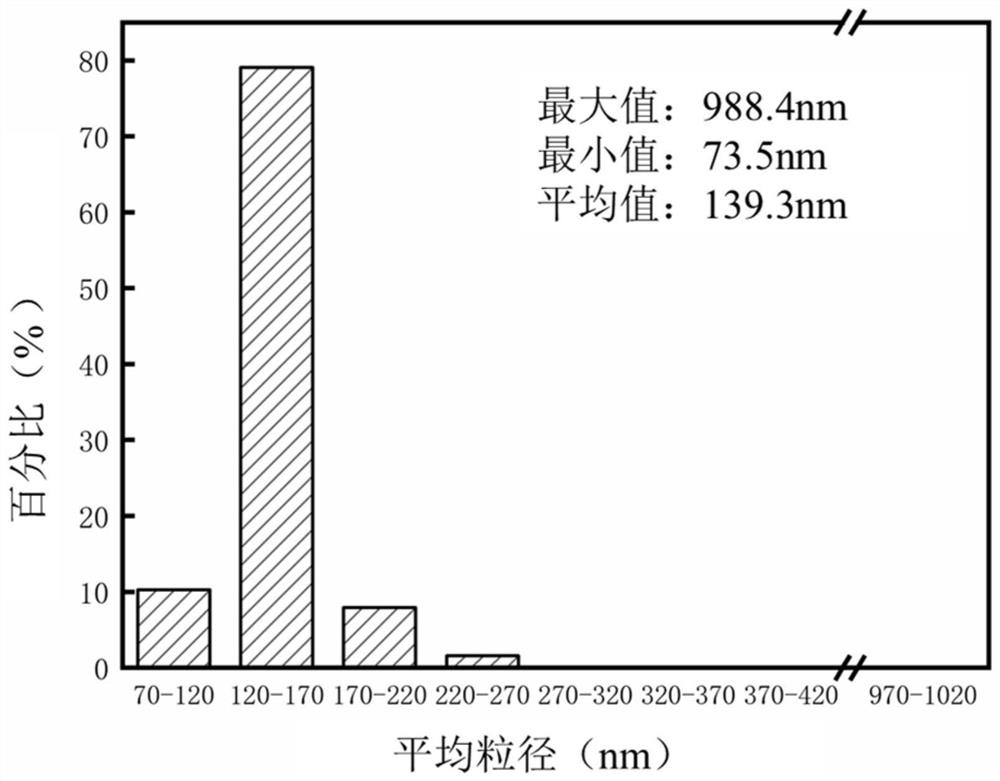

[0056] The high-permeability anti-fouling nanofiber separation membrane prepared in the above examples 1-7 was measured at a temperature of 25°C to measure its pore size distribution, and at a pressure of 0.2MPa and a temperature of 25°C to measure its filter polystyrene microspheres (1g / L) pure water flux before and after the solution, the specific test method is to test under pure water for 3 hours, then replace it with 1g / L polysty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com