Grinding tool, machining method thereof, grinding and polishing device and grinding method

A processing method and technology of grinding method, applied in the direction of grinding/polishing safety device, grinding device, metal processing equipment, etc., can solve the problems of low use efficiency, abrasive sedimentation, melting, etc., to increase grinding or polishing efficiency, improve Service life and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

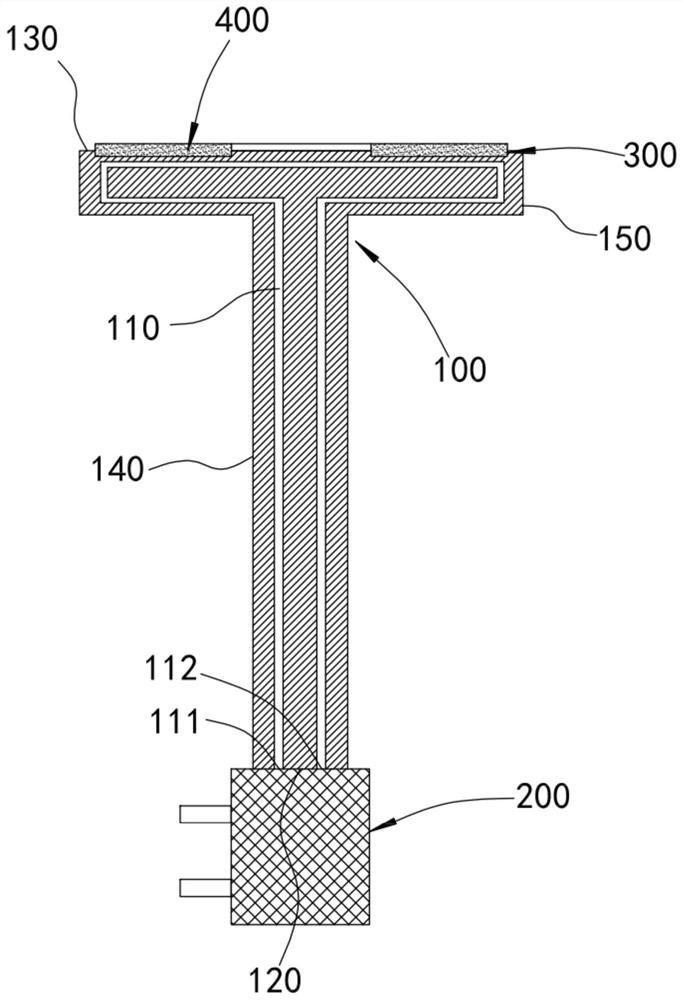

[0069] as attached figure 1 As shown, the abrasive tools of this program include

[0070] The carrier 100 is formed with a cooling channel 110, the inlet and outlet 111, 112 of the cooling channel 110 are located at the rear end surface 120 of the carrier 100, and the cooling channel 110 is separated from the carrier 100 the rear face extends to the front end 130;

[0071] The fluid slip ring 200 is connected to the rear end of the carrier 100 and the channel on it communicates with the inlet and outlet 111 and 112 of the cooling channel 110 to transport refrigerant;

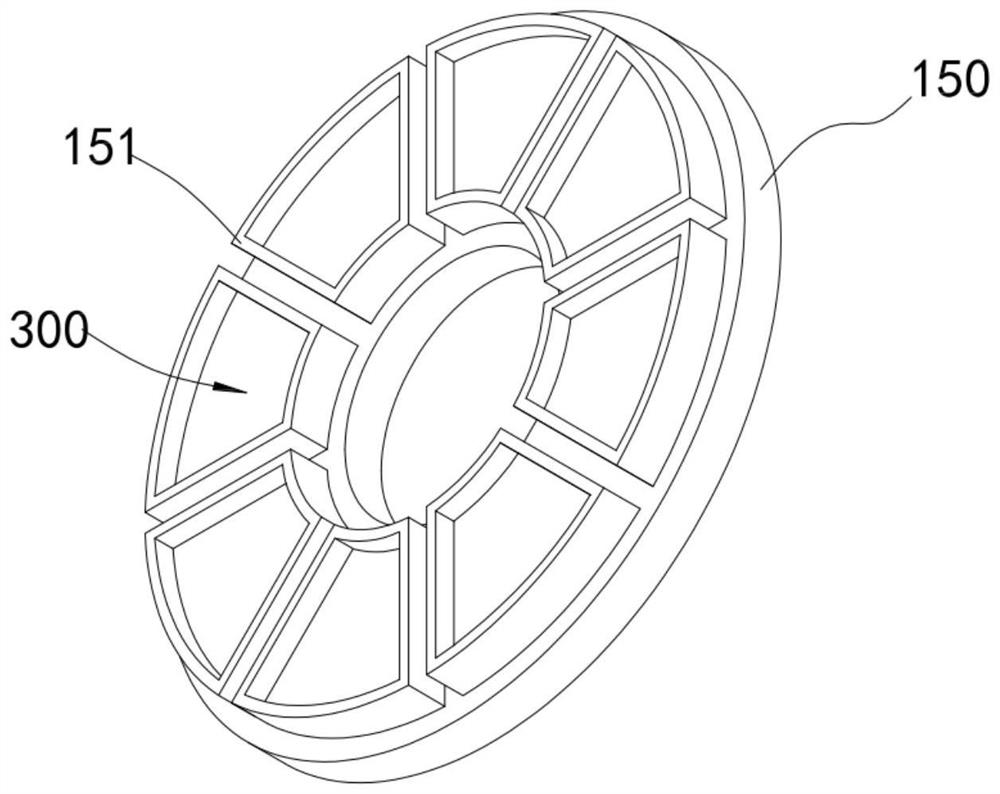

[0072] The accommodating space 300 is arranged at the front end of the carrier 100, and the material forming the accommodating space is a non-insulation material;

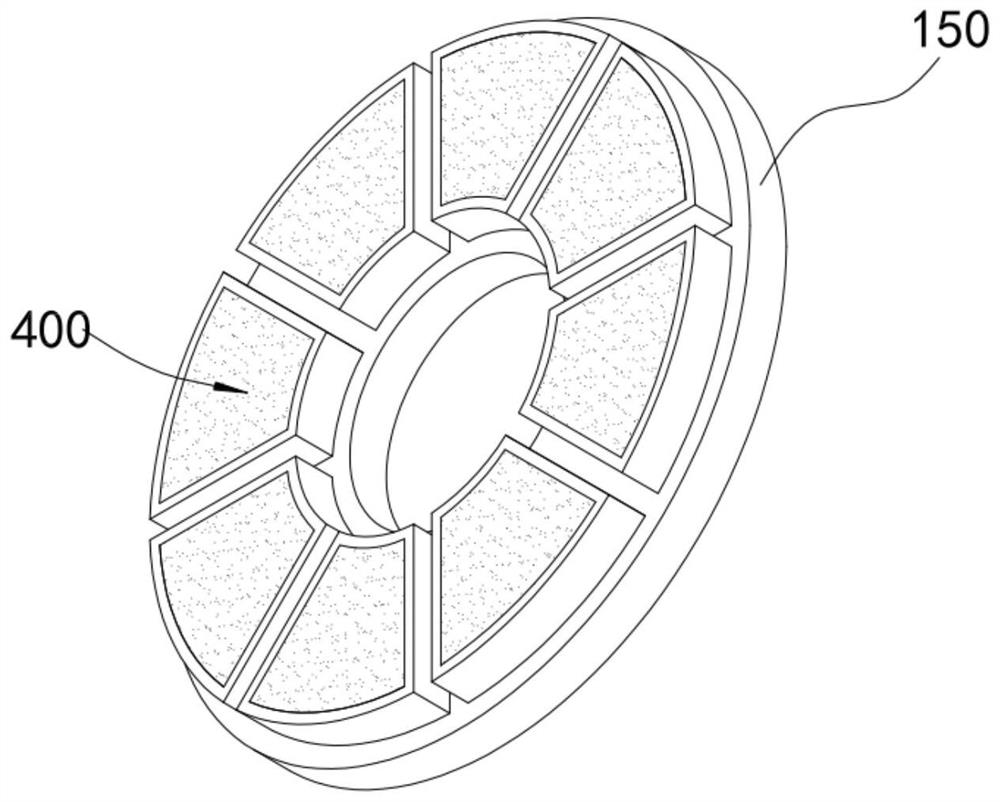

[0073] The frozen abrasive material 400 is disposed in the accommodating space 300 , which is a frozen body mixed with abrasive material.

[0074] By setting the cooling flow channel 110 on the carrier 100 and connecting the external refrigerant s...

Embodiment 2

[0095] When freezing is carried out by filling the cooling channel on the carrier 100 with refrigerant, the processing method of the abrasive tool is as follows, including the following steps:

[0096] S1, according to the different materials of the workpiece to be ground and / or the process requirements of different grinding process sections, uniformly mix abrasives, compatible materials and liquids that can solidify into solids in a certain proportion to obtain a mixture.

[0097] S2, provide the carrier 100 including the above-mentioned cooling channel, the front end of the carrier 100 is provided with accommodating space, and the rear end is provided with a fluid slip ring 200 , and the fluid slip ring 200 is connected to the refrigerant supply mechanism 700 .

[0098] S3, the refrigerant supply mechanism 700 continuously supplies refrigerant into the cooling channel 110, and the process temperature for the refrigerant to solidify the mixture and maintain the solidified stat...

Embodiment 3

[0112] This solution further provides a grinding and polishing device, at least including the grinding tool of the above-mentioned embodiment, as attached Figure 11 , attached Figure 12 As shown, the fluid slip ring 200 of the grinding tool is connected to the refrigerant supply mechanism 700, and the specific structure of the refrigerant supply mechanism 700 is a known technology, and will not be repeated here. The refrigerant supplied by the refrigerant supply mechanism 700 may be commonly used cooling media such as liquid nitrogen, ethylene glycol, or iced brine. The vehicle 100 is connected with a driving mechanism 900 for driving it to rotate.

[0113] During operation, the driving mechanism 900 drives the carrier 100 to rotate, and the refrigerant supply mechanism 700 continuously supplies refrigerant into the refrigerant channel to keep the frozen grinding materials frozen and kept warm. During grinding, the grinding can be realized by feeding the workpiece to the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com