Intrinsic safety type carbon dioxide gasifying agent and preparation method thereof

A technology of carbon dioxide and gasification agent, which is applied in the direction of non-explosive desensitizer/passivator, offensive equipment, non-explosive/non-thermal agent components, etc. It can solve the problems of poor safety and difficulty, and achieve short reaction time, The effect of fast burning speed, ensuring safety and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

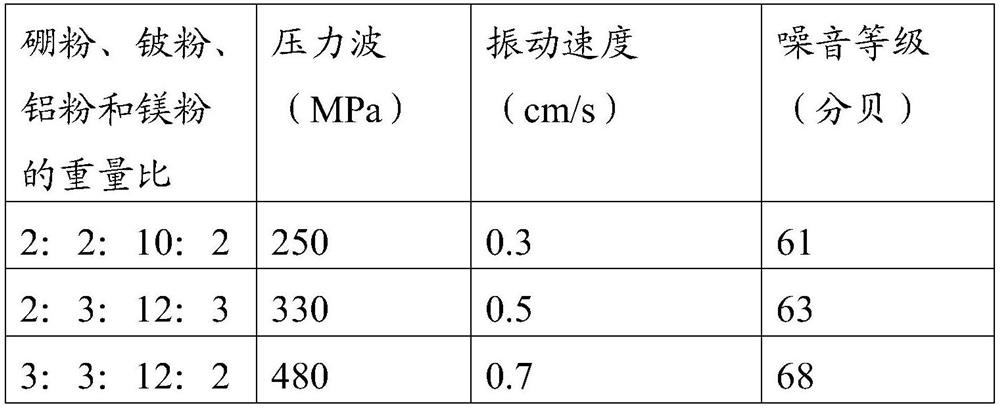

Embodiment 1

[0025] Embodiment 1: a kind of intrinsically safe carbon dioxide gasification agent, comprises solid fuel, deactivator, catalyzer and curing agent; Wherein, described solid fuel is made of boron powder, metal beryllium powder, metal aluminum powder and metal magnesium powder by weight The passivation agent is calcium chloride; the catalyst is nano silver; the curing agent is polyurethane or epoxy resin; the solid fuel, calcium chloride, nano The weight ratio of silver and polyurethane or epoxy resin is 16:2:0.1:1.

[0026] In the intrinsically safe carbon dioxide gasification agent described in the present embodiment 1, the boron powder selects the granular powder that the mesh number is 750, the beryllium powder selects the granular powder that the mesh number is 2000, and the aluminum powder selects the granular powder that the mesh number is 700, Magnesium powder adopts particle powder with mesh number of 500; calcium chloride adopts particle powder with mesh number of 200;...

Embodiment 2

[0028] Embodiment 2: a kind of intrinsically safe carbon dioxide gasification agent, comprises solid fuel, deactivator, catalyzer and curing agent; Wherein, described solid fuel is made of boron powder, metal beryllium powder, metal aluminum powder and metal magnesium powder by weight The passivation agent is calcium oxide; the catalyst is nano-nickel; the curing agent is polyurethane or epoxy resin; the solid fuel, calcium oxide, nano-nickel and The weight ratio of polyurethane or epoxy resin is 20:3:0.2:1.5.

[0029] In the intrinsically safe carbon dioxide gasification agent described in the present embodiment 2, the boron powder selects the granular powder that the mesh number is 1500, the beryllium powder selects the granular powder that the mesh number is 3000, and the aluminum powder selects the granular powder that the mesh number is 1000, The magnesium powder adopts the particle powder with the mesh number of 800; the calcium oxide adopts the particle powder with the ...

Embodiment 3

[0031]Embodiment 3: a kind of intrinsically safe carbon dioxide gasification agent, comprises solid fuel, deactivator, catalyzer and curing agent; Wherein, described solid fuel is made of boron powder, metal beryllium powder, metal aluminum powder and metal magnesium powder by weight The passivation agent is calcium carbonate; the catalyst is nano-silver; the curing agent is polyurethane or epoxy resin; the solid fuel, calcium carbonate, nano-silver and The weight ratio of polyurethane or epoxy resin is 20:3:0.2:1.5.

[0032] In the intrinsically safe carbon dioxide gasification agent described in the present embodiment 3, the boron powder selects the granular powder that the mesh number is 3000, the beryllium powder selects the granular powder that the mesh number is 3000, and the aluminum powder selects the granular powder that the mesh number is 2000, Magnesium powder adopts particle powder with mesh number of 1000; calcium carbonate adopts particle powder with mesh number ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com