Regenerated PA6/POK alloy reinforced wear-resistant material for automobile suspension plane bearing and preparation method of regenerated PA6/POK alloy reinforced wear-resistant material

A technology of plane bearing and automobile suspension, applied in the field of polymer materials, can solve the problems of overwhelmed manufacturing industry and dependence on imports of adiponitrile, so as to reduce the water absorption rate, reduce the risk of price increase and supply interruption, and meet the wear resistance performance. and dimensional stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

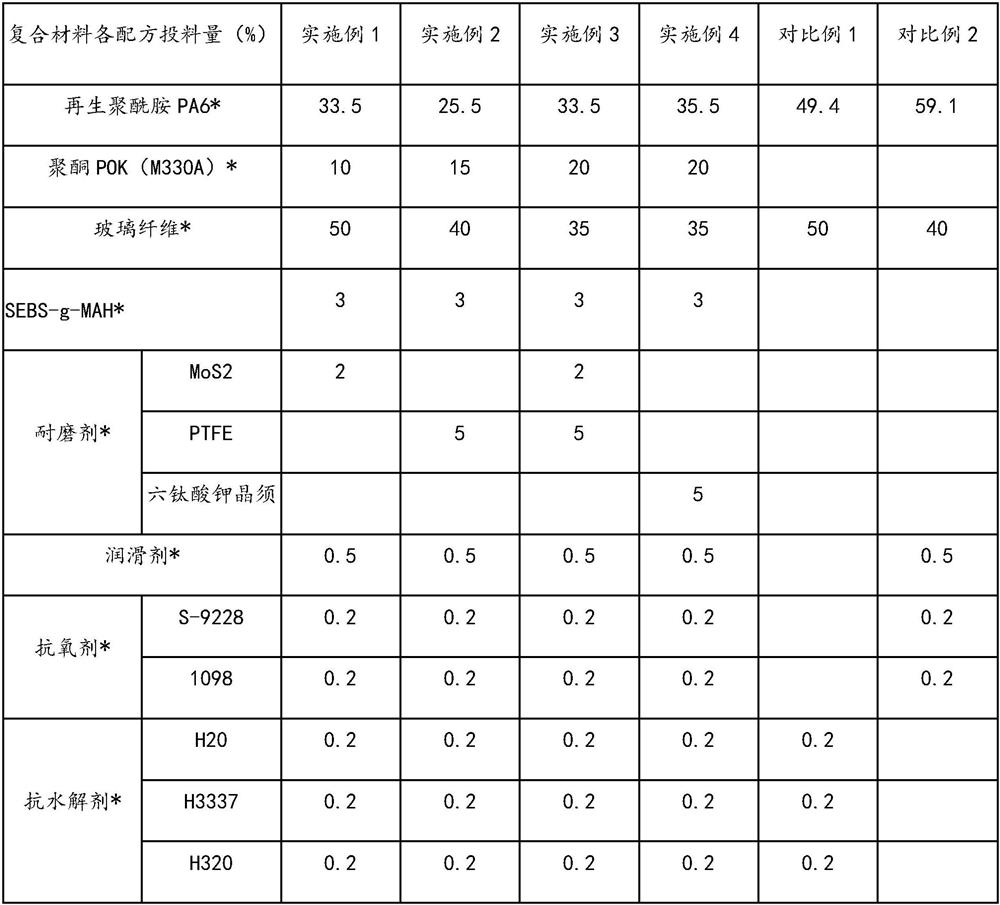

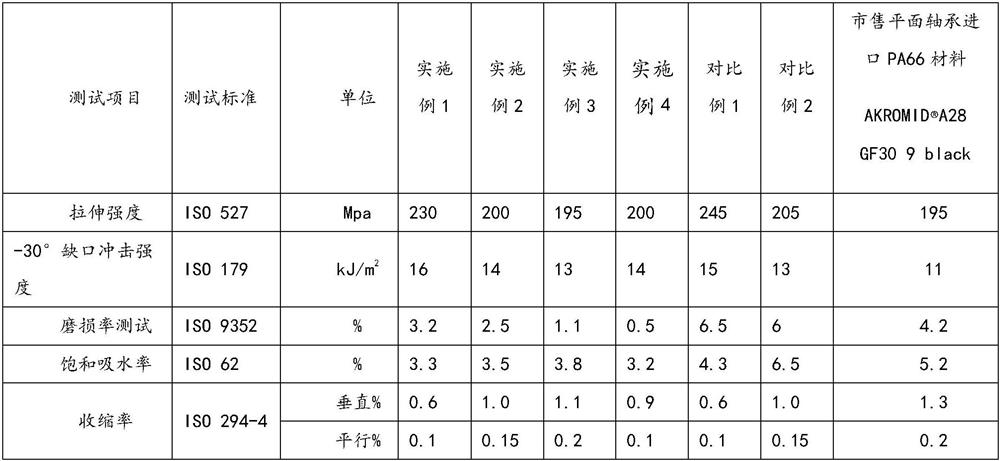

Embodiment 1-4 and comparative example 1-2

[0034] Prepare according to following method and be used for the regeneration PA6 / POK alloy reinforced wear-resistant material of automobile suspension plane bearing:

[0035] S1, material preparation: take each raw material component according to the ratio formula in Table 1;

[0036] S2. Premix: Mix polyamide regenerated PA6 resin, polyketone POK resin, antioxidant, wear-resistant agent, lubricant, and compatibilizer in a low-speed mixer to obtain a premix; extrude from the prepared plastic The main feeding and unloading of the machine;

[0037] S3, side material of extruder: lower glass fiber;

[0038] S4. Vacuum deashing negative pressure value: -0.08MPa;

[0039] S5. Melt extrusion: the premixed material + side material is melted and extruded by a twin-screw extruder at 235-265 ° C, pelletized by hot ring cutting, and air-cooled to obtain a recycled PA6 / POK alloy reinforced wear-resistant material;

[0040] The screw diameter of the twin-screw extruder is 65mm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| draft ratio | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com