Method for preparing LDHs/GO-MA self-repairing anti-corrosion coating

A technology for corroding coatings and coatings, applied in the field of materials, can solve the problems of shortened service life and corrosion of coatings, and achieve the effects of improving bonding strength, improving corrosion inhibition efficiency, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

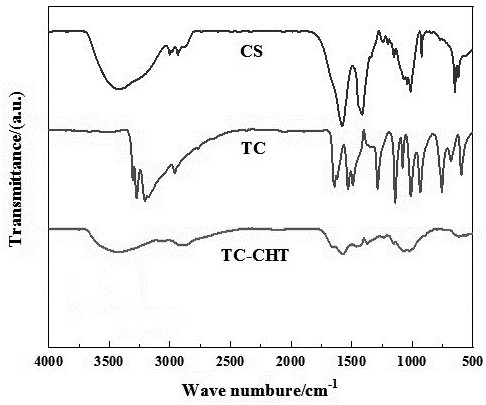

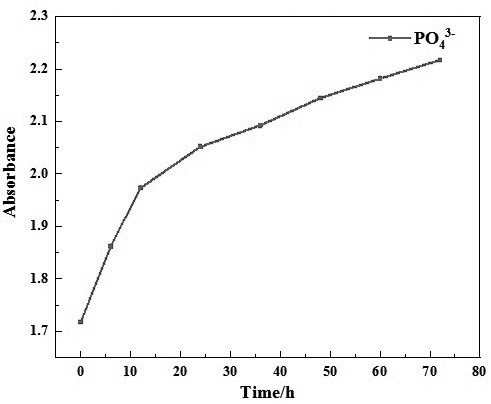

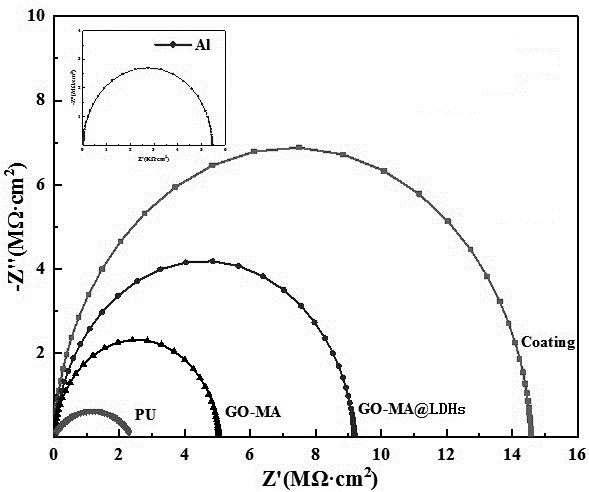

[0027] Example 1: Prepare a saturated trisodium phosphate solution at room temperature, weigh 2 g of magnesium-aluminum layered double hydroxide, disperse in the above saturated solution, ultrasonically oscillate for 30 min, then magnetically stir for 4 h, and filter the solution with suction And the obtained product was washed several times with deionized water and ethanol, and the washed product was dried in an oven at 60°C for 8 h and then ground into a powder, which was recorded as powder A; 10 ml of acetic acid was dispersed in 30 ml of deionized water, and then Slowly add 0.8 g of chitosan during the stirring process to obtain a viscous liquid. After the liquid is clarified, add 0.53 g of thiocarbohydrazide. After stirring for 45 min, add 2 ml of formaldehyde. Mix well at room temperature for 12 h to obtain a gelatinous solution. Gel-like mixture, sodium hydroxide aqueous solution was added to the gel-like mixture, the precipitate obtained by neutralization was washed wit...

Embodiment 2

[0028] Example 2: Prepare a saturated trisodium phosphate solution at room temperature, weigh 2 g of magnesium-aluminum layered double hydroxide, disperse it in the above saturated solution, stir it magnetically for 4 h after ultrasonic oscillation for 30 min, and filter the solution with suction And the obtained product was washed several times with deionized water and ethanol, and the washed product was dried in an oven at 60°C for 8 h and then ground into a powder, which was recorded as powder A; 10 ml of acetic acid was dispersed in 30 ml of deionized water, and then Slowly add 0.8 g of chitosan during the stirring process to obtain a viscous liquid. After the liquid is clarified, add 0.53 g of thiocarbohydrazide. After stirring for 45 min, add 2 ml of formaldehyde. Mix well at room temperature for 12 h to obtain a gelatinous solution. Gel-like mixture, sodium hydroxide aqueous solution was added to the gel-like mixture, the precipitate obtained by neutralization was washed...

Embodiment 3

[0029]Example 3: Prepare a saturated trisodium phosphate solution at room temperature, weigh 2 g of magnesium-aluminum layered double hydroxide, disperse it in the above saturated solution, stir it magnetically for 4 h after ultrasonic oscillation for 30 min, and filter the solution with suction And the obtained product was washed several times with deionized water and ethanol, and the washed product was dried in an oven at 60°C for 8 h and then ground into a powder, which was recorded as powder A; 10 ml of acetic acid was dispersed in 30 ml of deionized water, and then Slowly add 0.8 g of chitosan during the stirring process to obtain a viscous liquid. After the liquid is clarified, add 0.53 g of thiocarbohydrazide. After stirring for 45 min, add 2 ml of formaldehyde. Mix well at room temperature for 12 h to obtain a gelatinous solution. Gel-like mixture, sodium hydroxide aqueous solution was added to the gel-like mixture, the precipitate obtained by neutralization was washed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com