A kind of preparation method of compound pomace distilled wine

A technology of distilled wine and pomace, which is applied in the field of preparation of compound pomace distilled wine, can solve the problems that affect the high-quality development of the fruit processing industry, reduce the utilization rate of raw materials and industrial added value, and cannot be effectively utilized, so as to improve Utilization of raw materials and added value of products, avoiding perishable, strong typical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

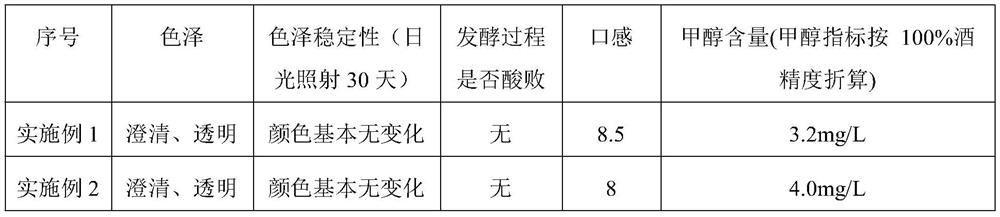

Examples

Embodiment 1

[0044] (1) Acceptance of raw materials: mulberry, blueberry, bayberry and other processed skin residues;

[0045] Specifically, the mulberry varieties are the "Big Ten" varieties with strong fruit aroma, high sugar content, and fully matured mulberries. After the mulberry fruits are fully matured and picked, they will be transported to the factory on the same day, and only those who pass the inspection can be processed; blueberries and bayberry are also used in After fully ripe picking, they will be transported to the factory on the same day, and only those who pass the inspection can be processed; those who have passed the inspection and acceptance are free of pesticide residues, heavy metals exceeding the standard, no disease, insect, mildew, rotten, and immature fruits; they can be placed on the conveyor belt Mildew, unripe fruit and other impurities such as sediment, branches and leaves are removed by hand; the fruit stalks at the bottom of mulberry, blueberry and bayberry ...

Embodiment 2

[0075] (1) Acceptance of raw materials: mulberry, blueberry, bayberry and other processed skin residues;

[0076] Specifically, the mulberry varieties are the "Big Ten" varieties with strong fruit aroma, high sugar content, and fully matured mulberries. After the mulberry fruits are fully matured and picked, they will be transported to the factory on the same day, and only those who pass the inspection can be processed; blueberries and bayberry are also used in After fully ripe picking, they will be transported to the factory on the same day, and only those who pass the inspection can be processed; those who have passed the inspection and acceptance are free of pesticide residues, heavy metals exceeding the standard, no disease, insect, mildew, rotten, and immature fruits; they can be placed on the conveyor belt Mildew, unripe fruit and other impurities such as sediment, branches and leaves are removed by hand; the fruit stalks at the bottom of mulberry, blueberry and bayberry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com