P-type bismuth telluride-based alloy material and preparation method thereof

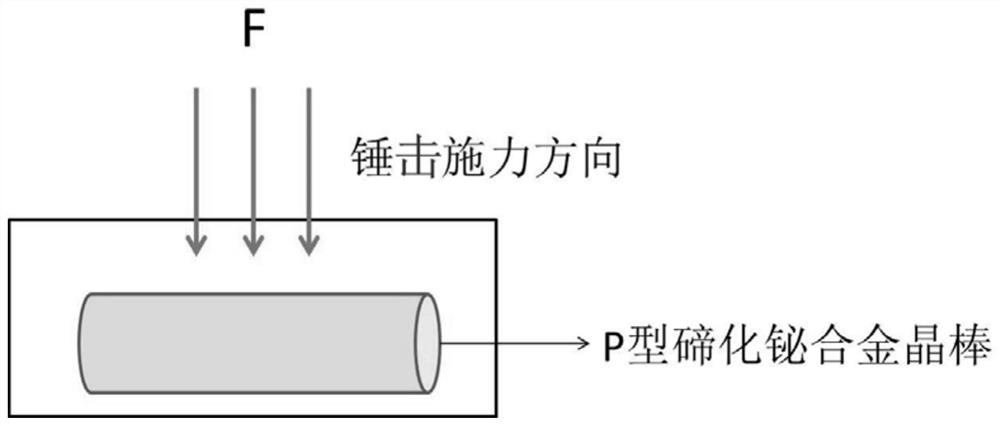

A bismuth telluride-based alloy technology, applied in thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of difficult processing, weak processing strength, low yield, etc., to improve mechanical properties , high orientation, and the effect of improving thermoelectric properties and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

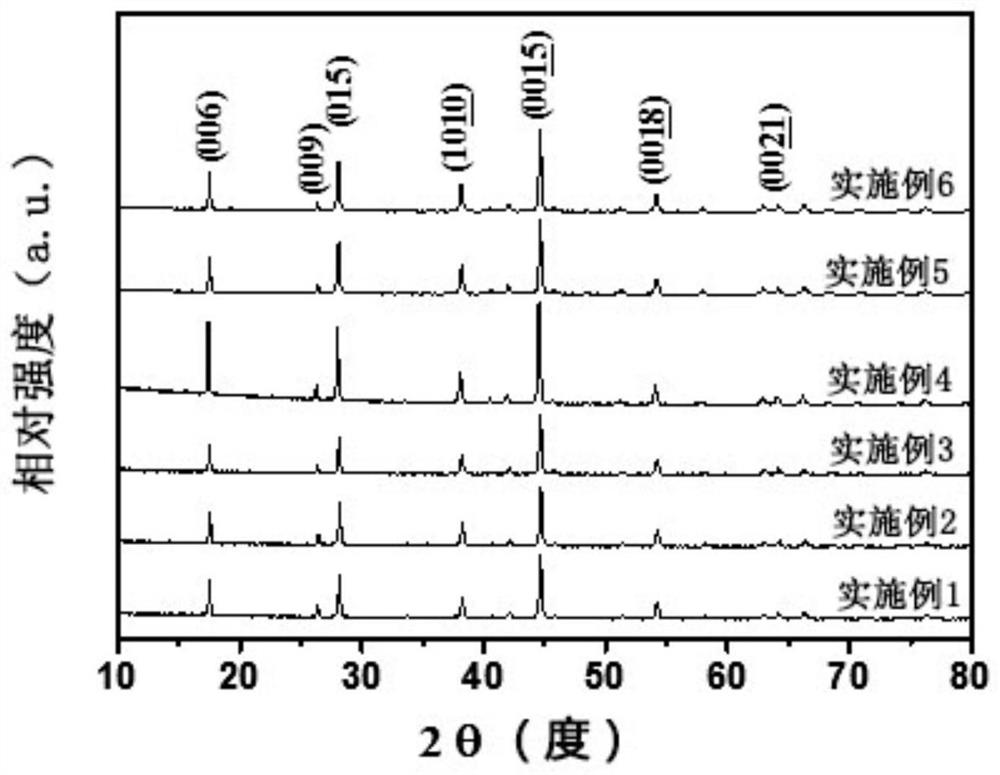

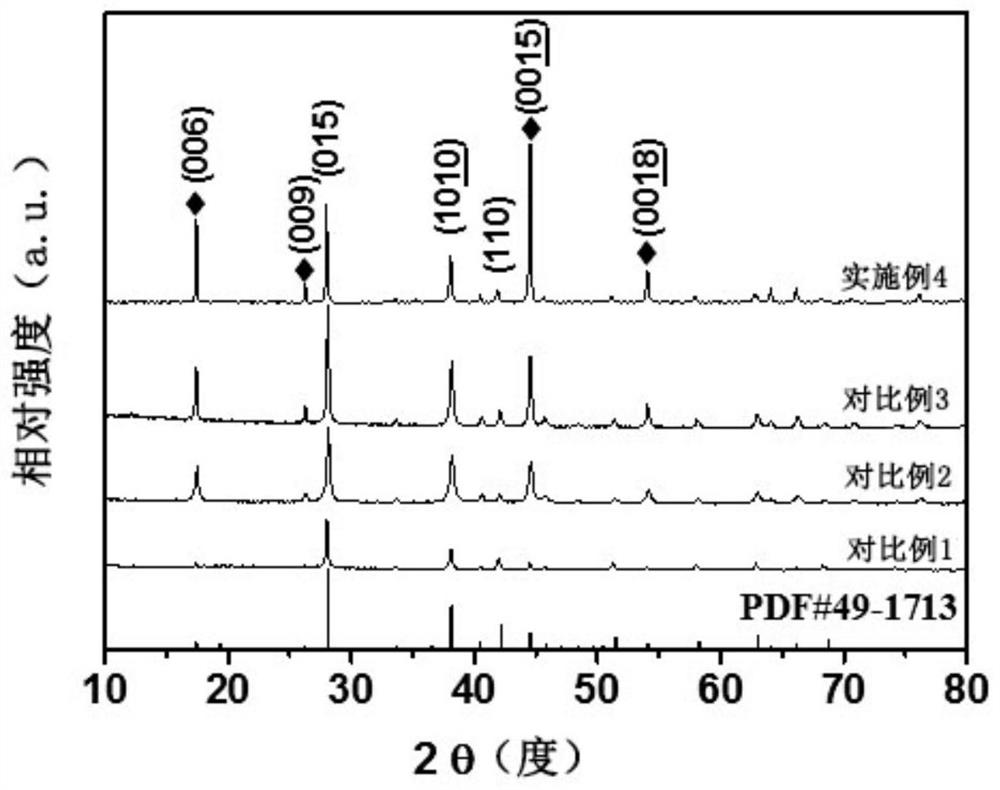

Examples

Embodiment 1

[0041] An embodiment of a p-type bismuth telluride-based alloy material and a preparation method thereof of the present invention is as follows:

[0042] (1) With p-type Bi 0.5 Sb 1.5 Te 3 The stoichiometric ratio of the raw materials is 1.2Kg in total of Bi, Sb, and Te block materials, which are added to the high borosilicate glass tube in the order of Sb, Bi, and Te, and then vacuum-sealed;

[0043] (2) Put the high borosilicate glass tube into the swing furnace and preheat it at 700°C for 5 minutes, then swing and smelt it for 5 minutes, then take out the high borosilicate glass tube and shake it well, then put it back into the swing furnace for refining for 2 minutes, then take it out The high borosilicate glass tube leans vertically on the iron frame, tap the glass tube to make the melt on the wall of the glass tube slide down, the bubbles in the melt rise up, exhaust the bubbles, and cool down to room temperature naturally;

[0044] (3) Fix the glass tube cooled in st...

Embodiment 2

[0048] An embodiment of a p-type bismuth telluride-based alloy material and a preparation method thereof of the present invention is as follows:

[0049] (1) With p-type Bi 0.5 Sb 1.5 Te 3 The stoichiometric ratio of the raw materials is 1.2Kg in total of Bi, Sb, and Te block materials, which are added to the high borosilicate glass tube in the order of Sb, Bi, and Te, and then vacuum-sealed;

[0050] (2) Put the high borosilicate glass tube into the swing furnace and preheat it at 700°C for 3 minutes, then swing and smelt it for 5 minutes, then take out the high borosilicate glass tube and shake it well, then put it back into the swing furnace for refining for 3 minutes, then take it out The high borosilicate glass tube leans vertically on the iron frame, tap the glass tube to make the melt on the wall of the glass tube slide down, the bubbles in the melt rise up, exhaust the bubbles, and cool down to room temperature naturally;

[0051] (3) Fix the glass tube cooled in st...

Embodiment 3

[0055] An embodiment of a p-type bismuth telluride-based alloy material and a preparation method thereof of the present invention is as follows:

[0056] (1) With p-type Bi 0.5 Sb 1.5 Te 3 The stoichiometric ratio of the raw materials is 1.5Kg of the raw materials Bi, Sb, and Te block materials, and they are added to the high borosilicate glass tube in the order of Sb, Bi, and Te, and the tube is vacuum sealed;

[0057] (2) Put the high borosilicate glass tube into the swing furnace and preheat it at 700°C for 5 minutes, then swing and smelt it for 7 minutes, then take out the high borosilicate glass tube and shake it well, then put it back into the swing furnace for refining for 3 minutes, then take it out The high borosilicate glass tube leans vertically on the iron frame, tap the glass tube to make the melt on the wall of the glass tube slide down, the bubbles in the melt rise up, exhaust the bubbles, and cool down to room temperature naturally;

[0058] (3) Fix the glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com