Ultrahigh-strength steel having excellent cold workability and ssc resistance, and manufacturing method therefor

A technology of ultra-high-strength steel and cold workability, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve problems such as weakened crack growth resistance, surface cracks, easy hydrogen migration, etc., and achieve excellent cold workability and excellent SSC resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0064] Hereinafter, the present disclosure will be described in more detail through examples. However, it should be noted that the following embodiments are only intended to illustrate the present disclosure in more detail, not to limit the scope of the present disclosure. This is because the scope of the present disclosure is defined by matters set forth in the claims and reasonably inferred therefrom.

[0065] (Example)

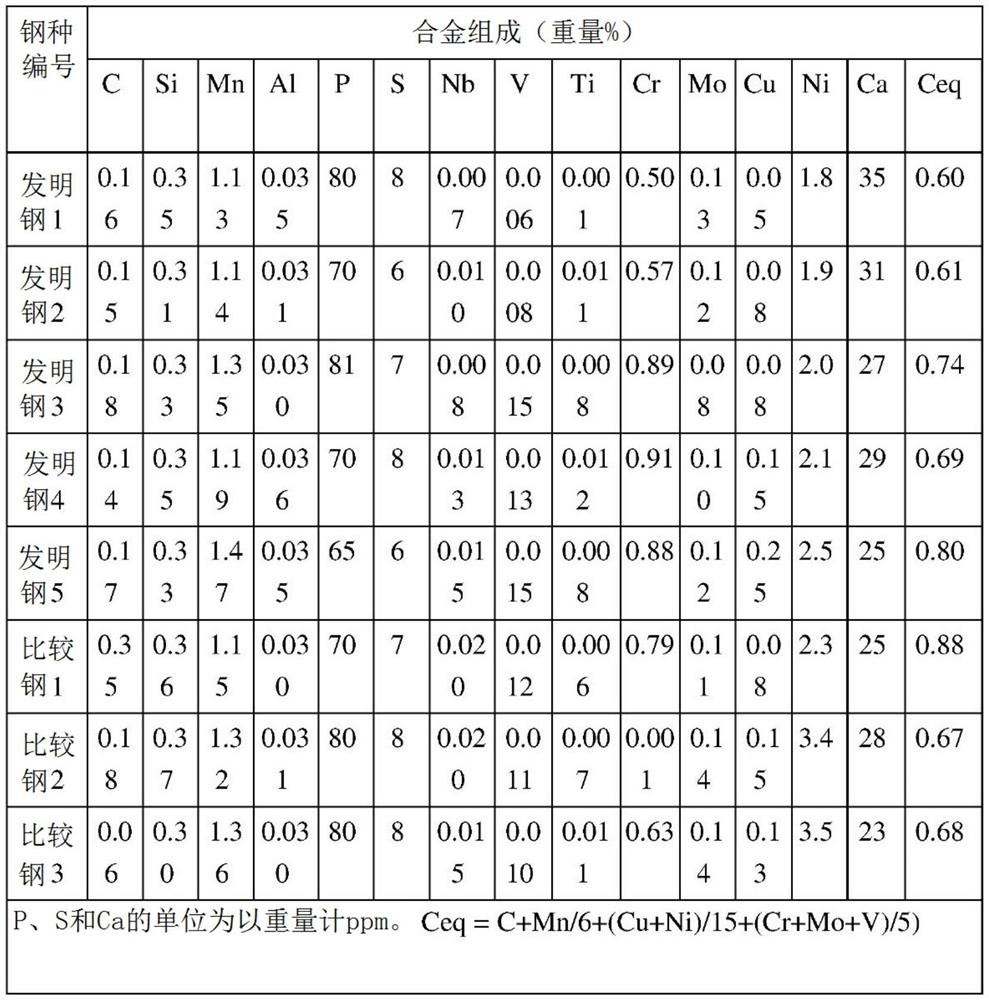

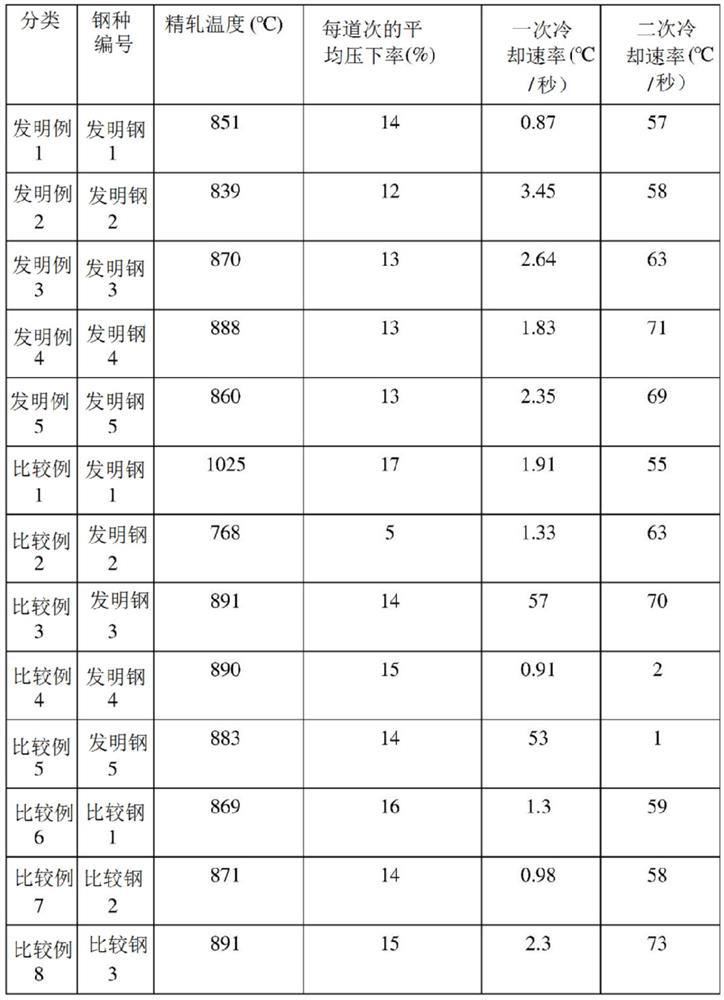

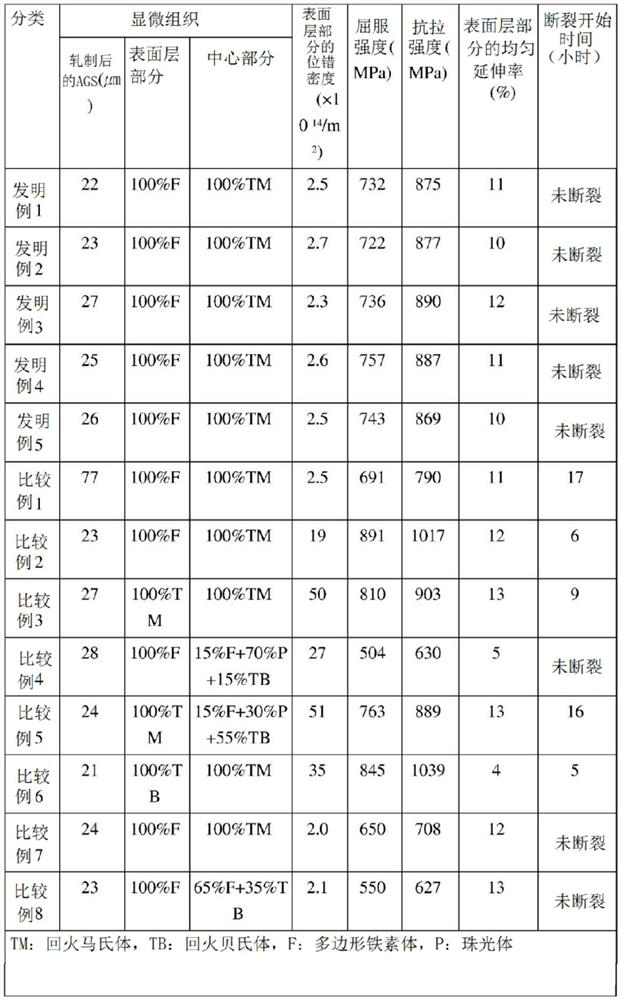

[0066] After reheating the billets each having the alloy composition shown in Table 1 below at 1100°C, the billets were hot-rolled and cooled under the conditions shown in Table 2 below, and then heat-treated by tempering at 650°C for 30 minutes, To manufacture hot-rolled steel with a thickness of 80mm. After hot rolling, the hot rolled steel was cooled to room temperature and then heated at 890°C for an additional 30 minutes. During cooling, the primary cooling stop temperature is 700°C, and the secondary cooling stop temperature is 27°C.

[0067] For ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com