Catalyst used for catalytic combustion of VOCs and capable of resisting alkali metal poisoning and preparation method of catalyst

A catalytic combustion and catalyst technology, applied in combustion methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of not fully meeting the requirements of anti-alkali metal poisoning and insignificant benefits, etc. Achieve the effect of improving the anti-alkali metal poisoning performance, high catalytic activity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 0.8 g of the prepared Co-CAT-1 sample was immersed in 8 mL of tetramethylsiloxane (TMOS) and kept at 60 °C for 12 h. The wetted sample was then washed several times with methanol to remove excess TMOS, and the sample was placed in a quartz tube after washing. with 15 mL / min of N 2 The air flow was bubbled in 0.1 M HCl solution, and the generated humid air flow induced the hydrolysis of TMOS at 50 °C for 30 h. After drying for 5 h, the sample was dried in 150 mL / min of N 2 Carbonization was carried out at 600°C for 4h in air flow environment. The obtained samples were calcined at 500 °C for 2 h in an air atmosphere (heating rate 1 °C / min). Finally, a one-dimensional cowpea-like silica-encapsulated cobalt tetroxide catalyst is obtained.

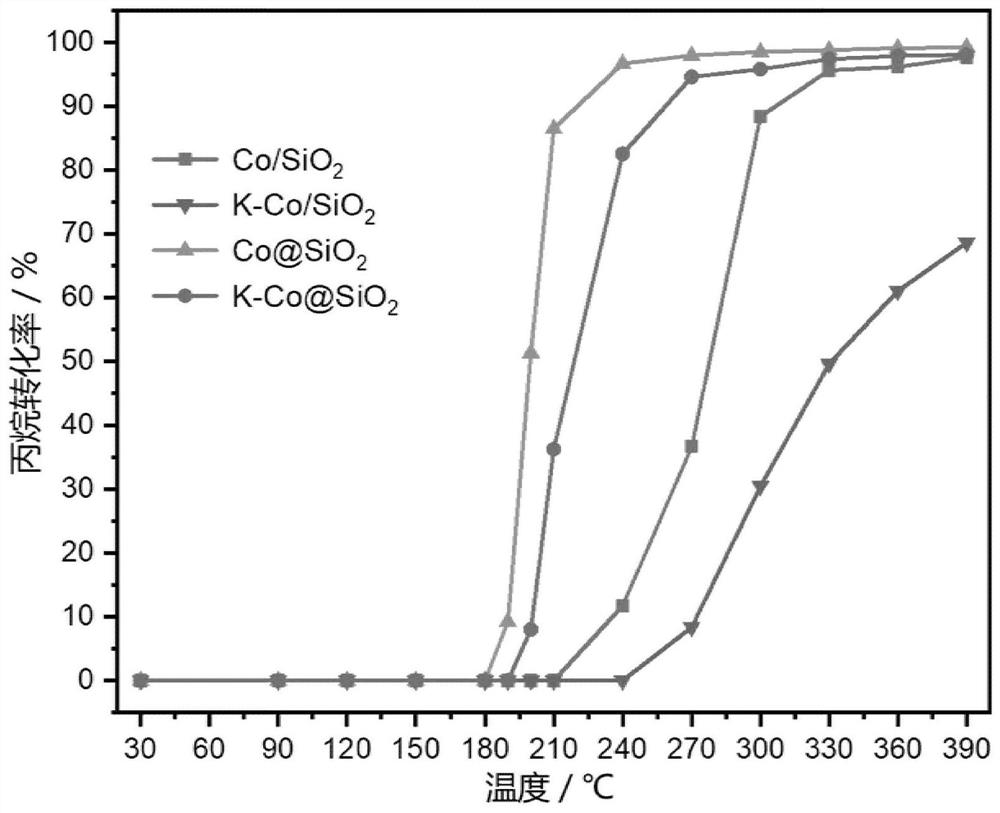

[0028] Test the catalytic activity and anti-alkali metal poisoning performance of the above catalyst: put 0.3 g of the prepared catalyst into a fixed bed reactor for activity test, the composition of the simulated reaction gas is: 0....

Embodiment 2

[0030] 0.8 g of the prepared Co-CAT-1 sample was immersed in 8 mL of tetramethylsiloxane (TMOS) and kept at 60 °C for 12 h. The wetted sample was then washed several times with methanol to remove excess TMOS, and the sample was placed in a quartz tube after washing. with 15 mL / min of N 2 The air flow was bubbled in deionized water, and the generated humid air flow induced the hydrolysis of TMOS at 60 °C for 30 h. After drying for 5 h, the sample was dried in 150 mL / min of N 2 Carbonization was carried out at 600 °C for 4 h in air flow environment. The obtained samples were calcined at 500 °C for 2 h in an air atmosphere (heating rate 1 °C / min). Finally, a one-dimensional cowpea-like silica-encapsulated cobalt tetroxide catalyst is obtained.

[0031] Test the catalytic activity and anti-alkali metal poisoning performance of the above catalyst: put 0.3 g of the prepared catalyst into a fixed bed reactor for activity test, the composition of the simulated reaction gas is: 0.2...

Embodiment 3

[0033]0.8 g of the prepared Co-CAT-1 sample was immersed in 8 mL of tetramethylsiloxane (TMOS) and kept at 60 °C for 12 h. The wetted sample was then washed several times with methanol to remove excess TMOS, and the sample was placed in a quartz tube after washing. with 15 mL / min of N 2 The air flow was bubbled in 0.05 M HCl solution, and the generated humid air flow induced the hydrolysis of TMOS at 50 °C for 30 h. After drying for 5 h, the sample was dried in 150 mL / min of N 2 Carbonization was carried out at 600°C for 3h in air flow environment. The obtained samples were calcined at 500 °C for 2 h in an air atmosphere (heating rate 1 °C / min). Finally, a one-dimensional cowpea-like silica-encapsulated cobalt tetroxide catalyst is obtained.

[0034] Test the catalytic activity and anti-alkali metal poisoning performance of the above catalyst: put 0.3 g of the prepared catalyst into a fixed bed reactor for activity test, the composition of the simulated reaction gas is: 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com