A Mesoporous Zr, Ce Co-doped Scr Catalyst

A SCR catalyst, co-doping technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of catalyst particle agglomeration, easy surface pollution, catalytic activity Reduce and other problems to achieve the effect of improving selectivity and improving water and sulfur resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

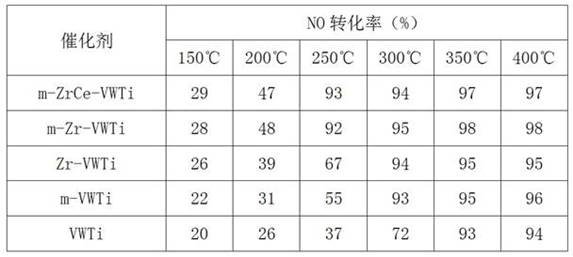

[0025] Add 0.128mol acetylacetone to 0.064mol tetrabutyl titanate to make the acetylacetone / Ti molar ratio = 2; then add 50mL stoichiometric ethanol solution of zirconium nitrate and stir for 2 hours to obtain a sol; place the sol in a water bath at 60°C After concentration, drying at 120°C for 6 hours, and then calcining at 500°C for 3 hours to obtain a Zr-doped titania carrier, wherein the added amount of zirconium nitrate is such that the molar ratio Zr / Ti=0.005-0.02. The prepared Zr-doped titania carrier was impregnated in 50 mL of ammonium paratungstate aqueous solution, refluxed in a water bath at 60 °C for 4 h, dried at 120 °C for 6 h, and then calcined at 500 °C for 2 h to obtain Zr-doped WO 3 / TiO 2 , where WO 3 The loading amount is 1wt%, denoted as ZR-WTi; Zr doped WO 3 / TiO 2 Immersed in 50 mL of ammonium metavanadate aqueous solution, refluxed in a water bath at 60 °C for 4 h, dried at 120 °C for 6 h, and then calcined at 500 °C for 2 h to obtain Zr-doped V 2 ...

Embodiment 2

[0030] On the basis of Example 1, when adding the ethanolic solution of 50mL of stoichiometric zirconium nitrate, add the methanol solution of 50mL of stoichiometric cerous chloride, other steps are the same as in Example 1, and Zr and Ce are co-doped Miscellaneous V 2 o 5 -WO 3 / TiO 2 The denitration catalyst is denoted as m-ZrCe-VWTi. The NO removal rate was evaluated in the same manner as in Example 1.

Embodiment 3

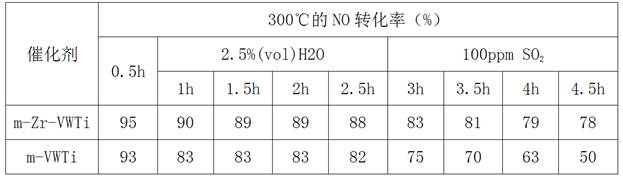

[0036] Example 3 Catalyst NH of the present invention 3 Selective catalytic reduction NO activity and water and sulfur resistance performance test

[0037] The reaction temperature is 300°C, and 2.5% (vol) H 2 O, after that, collect data every 0.5h, pass through H 2 After O 2h, 100ppm SO was introduced into the reaction system 2 , collect data once every 0.5h, continue to react for 2h to stop the reaction, and other reaction conditions are the same as in Example 1. The relevant test data are shown in Table 2.

[0038] Table 2. The effect of Zr doping on the water and sulfur resistance activity of the catalyst

[0039]

[0040] As can be seen from Table 2, the Zr element of the present invention is at V 2 o 5 -WO 3 / TiO 2 Doping in can not only improve the low temperature NH 3 Selective catalytic reduction of NO activity can also improve the anti-water and anti-sulfur activity of the SCR catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com