Denitration catalyst, preparation method thereof and denitration method

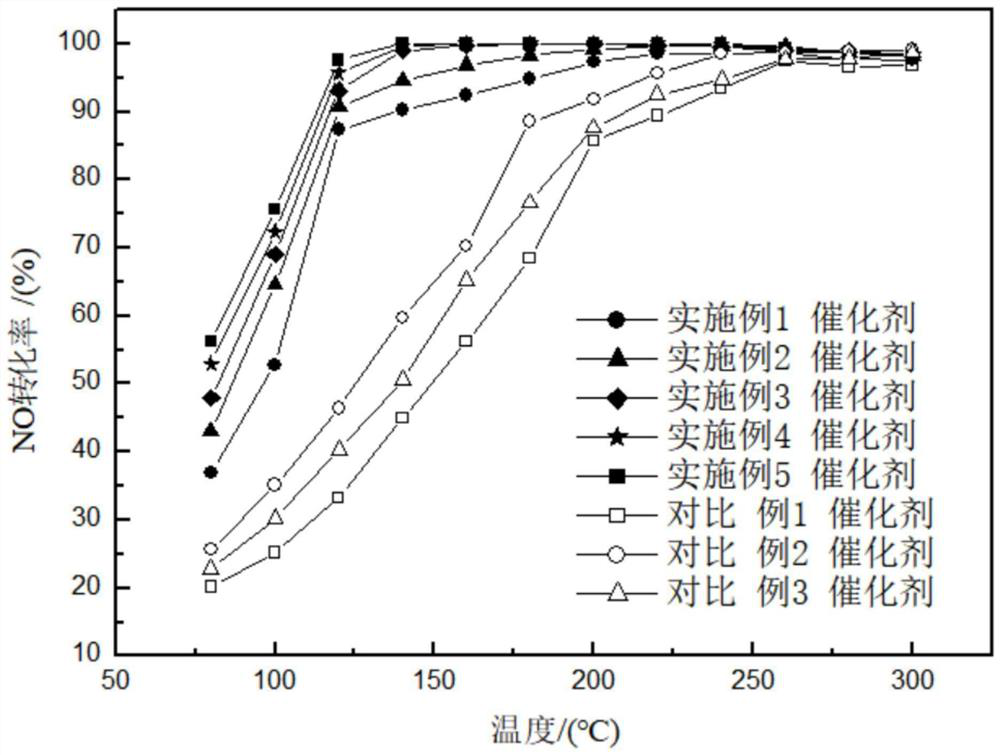

A denitration catalyst and catalyst technology, applied in the field of denitration, can solve the problems of low crystallinity, poor stability, and small specific surface area of porous titanium dioxide materials, and achieve the effect of promoting low temperature denitration performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] Some embodiments of the present invention provide a method for preparing a denitration catalyst, comprising the following steps:

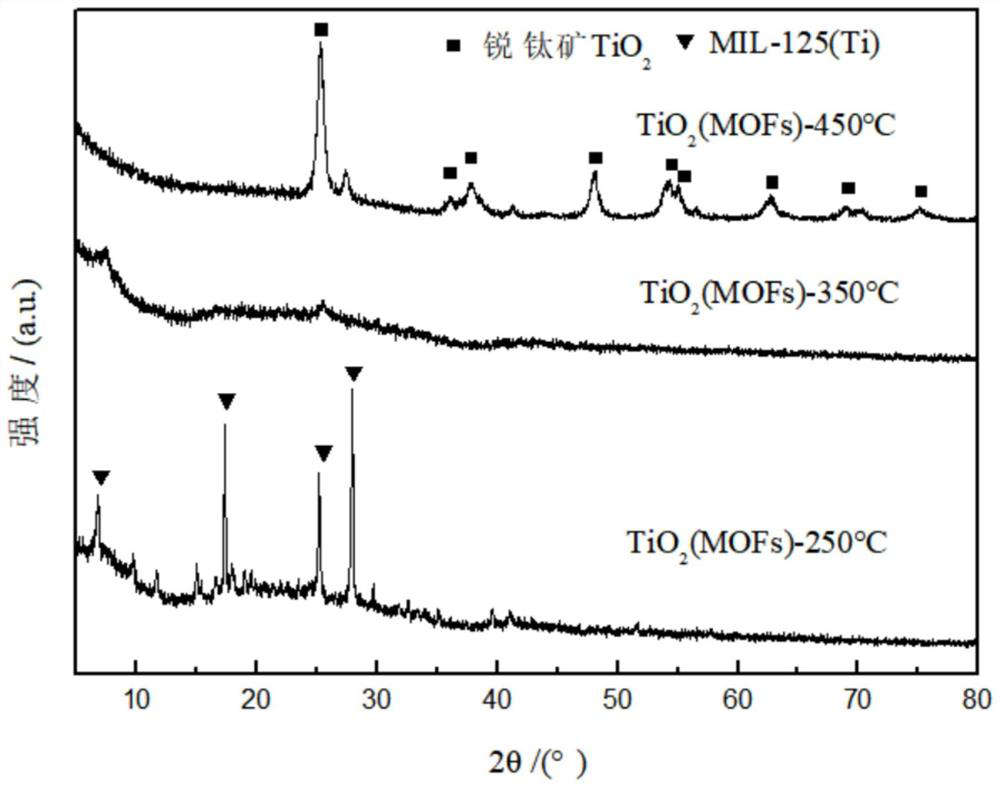

[0042] S1 Roasting MIL-125(Ti) powder to obtain MOFs derivative porous nano-TiO 2 ;

[0043] Described MIL-125 (Ti) powder is made through the following steps:

[0044] (1) Ultrasonically mix N,N-dimethylformamide, terephthalic acid and anhydrous methanol to obtain a transparent mixed solution; the N,N-dimethylformamide, terephthalic acid and The weight ratio of water and methanol is (47-57):(1-5):(2-8). By controlling the ratio of these to (47-57):(1-5):(2-8) to synthesize MIL-125 with uniform size, non-agglomerated spherical structure, no impurities and good crystal form ); terephthalic acid is mainly used as a ligand to form a complex with a Ti source; the difference in the ratio of N,N-dimethylformamide and anhydrous methanol will cause a difference in the degree of coordination between the metal ion and the organic ligand. This in t...

Embodiment 1

[0063] This embodiment provides a method for preparing a denitration catalyst, comprising the following steps:

[0064](1) Measure 54mL of N,N-dimethylformamide, 3g of terephthalic acid and 6mL of anhydrous methanol, and mix them uniformly by ultrasonic to obtain a transparent mixed solution.

[0065] (2) Add 1.56 mL of tetrabutyl titanate to the above mixed solution, continue ultrasonic stirring for 15 min, and then transfer to a stainless steel autoclave at 150° C. for 48 h.

[0066] (3) After the reaction is completed, the temperature is naturally lowered, the obtained mixed solution is suction-filtered, and then washed three times with N,N-dimethylformamide and methanol respectively and suction-filtered, and finally the washed product is put into a vacuum drying oven Dry overnight (24h) at 105°C to obtain MIL-125(Ti) powder.

[0067] (4) The MIL-125(Ti) powder prepared above was heated in a muffle furnace at 2°C / min to 350°C, and calcined for 3h to obtain MOFs derivative ...

Embodiment 2

[0071] This embodiment provides a method for preparing a denitration catalyst, comprising the following steps:

[0072] (1) Measure 54mL of N,N-dimethylformamide, 3g of terephthalic acid and 6mL of anhydrous methanol, and mix them uniformly by ultrasonic to obtain a transparent mixed solution.

[0073] (2) Add 1.56 mL of tetrabutyl titanate to the above mixed solution, continue ultrasonic stirring for 15 min, and then transfer to a stainless steel autoclave at 150° C. for 48 h.

[0074] (3) After the reaction is completed, the temperature is naturally lowered, the obtained mixed solution is filtered by suction, and then washed three times with N,N-dimethylformamide and methanol respectively and filtered by suction, and finally the washed product is put into a vacuum drying box Dry overnight at 105°C to obtain MIL-125(Ti) powder.

[0075] (4) The MIL-125(Ti) powder prepared above was heated to 350°C at a rate of 2°C / min in a muffle furnace, and calcined for 3h to obtain MOFs d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com