Preparation method of n-nonanal volatile gas sensitive material

A gas-sensitive material and volatile gas technology, which is applied in the analysis of materials, material resistance, material analysis by electromagnetic means, etc., can solve the problem of low detection sensitivity, and achieve the effect of improving detection sensitivity and specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A method for preparing a nikanone volatile gas sensitive material, including the following steps:

[0024] (1) Put WCL 6 Soluble in methanol solvent, weigh RUCL 3 , Put RUCL 3 Add to the mixed solvent while stirring;

[0025] (2) Transfer the mixed solution to the high pressure reaction kettle, sealed, naturally cooled, centrifuged, washed, dried to obtain a precursor;

[0026] (3) Precursing the precursor in an inert atmosphere to obtain the gas sensitive material;

[0027] (4) The obtained gas sensitive material was added to the deionized water grinding to form a paste, and then the paste was evenly applied to the outer surface of the gas sensor substrate and completely covered with the gold electrode, and naturally drying and formed a gas-sensitive coating at room temperature. Gas sensitive components.

[0028] Step (1), WCL 6 And the molar ratio of the methanol solvent is 1: 1, WCL 6 RUCL 3 The mass ratio is 60-90: 1; in step (2), the temperature of the sealed reaction ...

Embodiment 1

[0032] (1) Weigh 0.375 g WCL 6 Soluble in 80 mL of methanol solvent, weigh 5 mg rucl 3 Add to the mixed solvent while stirring;

[0033] (2) The mixed solution was moved to a high pressure reaction kettle, and the heat was 160 ° C for 24 h, and the precursor was obtained after centrifugation.

[0034] (3) Put the precursor is placed in an inert atmosphere to heat treatment 2 h at 300 ° C to obtain a gas sensitive material;

[0035] Among them, the prepared gas sensitive material components include WO 3-x And Ru, WO 3-x And the mass percentage of Ru is 99% and 1%, respectively, in this example WO 3-x W 18 O 49 .

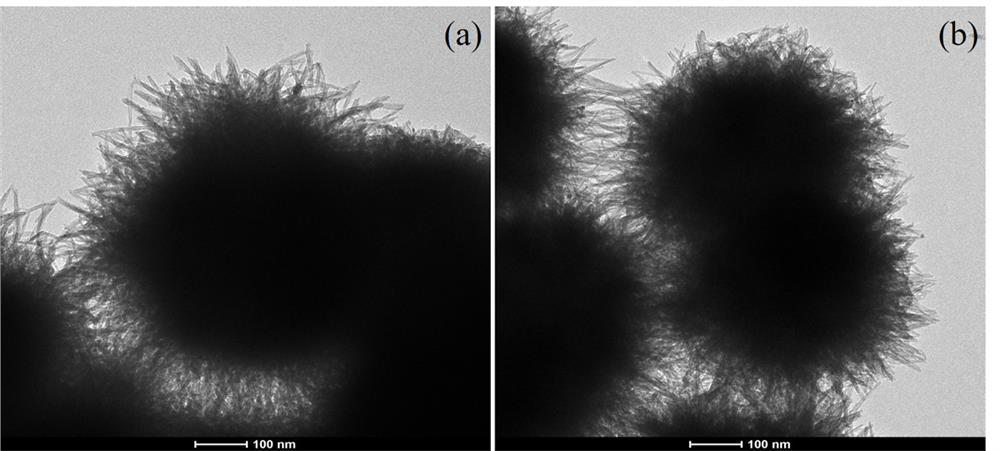

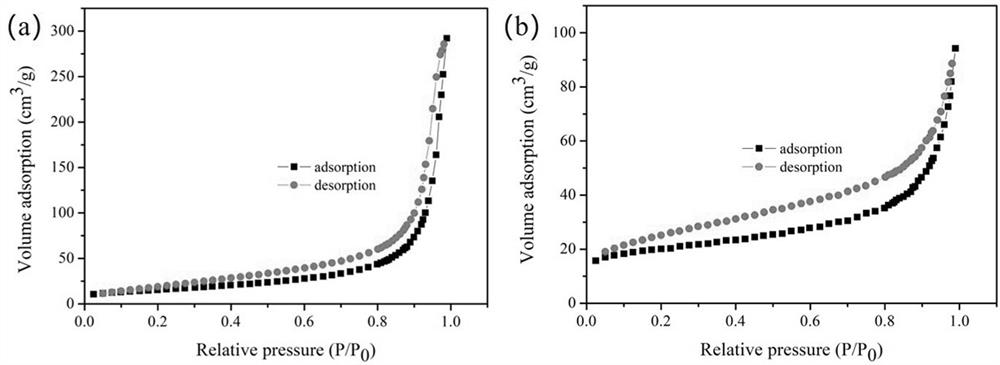

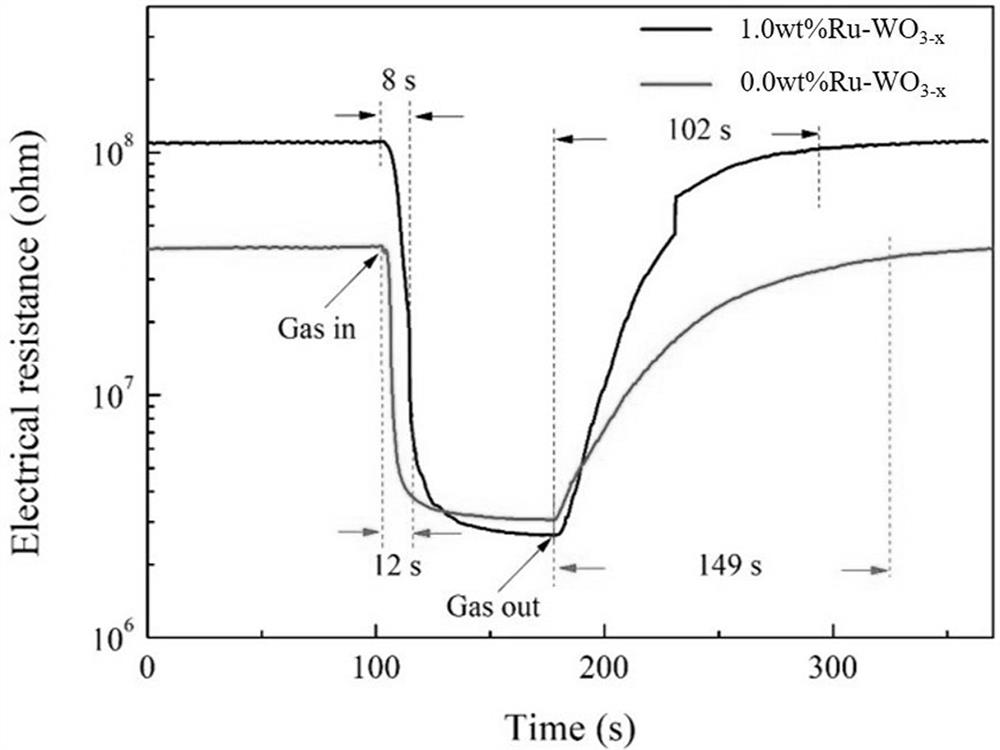

[0036] The prepared gas sensitive material was detected, and the transmissive electron microscope was observed, it will be apparent that the microstructure of the gas sensitive material is sea urchin, such as figure 1 Down, pure WO 3-x The average diameter of 700-800 nm, 1 wt% RU doped WO 3-x The average diameter is 600-700 nm, the grain size is significantly reduced; the...

Embodiment 2

[0038] The present embodiment differs from the first embodiment in that the Ag replacement RUCL is used in step (1). 3 , The components of the prepared gas sensitive material include WO 3-x And AG, the mass percentage is 99% and 1%, respectively; pure WO 3-x The specific surface is 17 m2 / g, 1 wt% Ag doped WO 3-x The specific surface is 50 m2 / g; when 1 ppm is oxylgenal aldehyde gas, 1 wt% Ag is doped with WO 3-x The sensitivity reaches 15.6, higher than pure WO 3-x Sensitivity (12.4); 1 WT% AG Doped WO 3-x Response / recovery time is 10 s and 122 s, faster than pure WO 3-x Response / recovery time (12 S / 149 s).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com