A kind of composite fermentation bacterial agent for manure composting

A technology of composite fermentation bacteria and fermentation bacteria, which is applied in the direction of bacteria, fungi, organic fertilizers, etc., can solve the problems of longer fermentation time, longer fermentation time, and more loss of nutrients, so as to improve the composting effect and prolong the fermentation time , Reduce the effect of fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

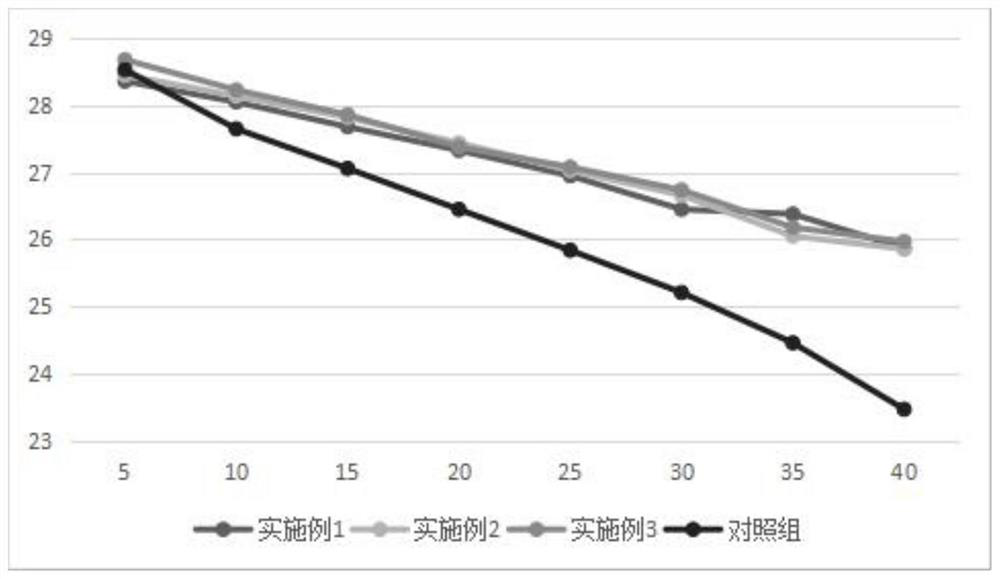

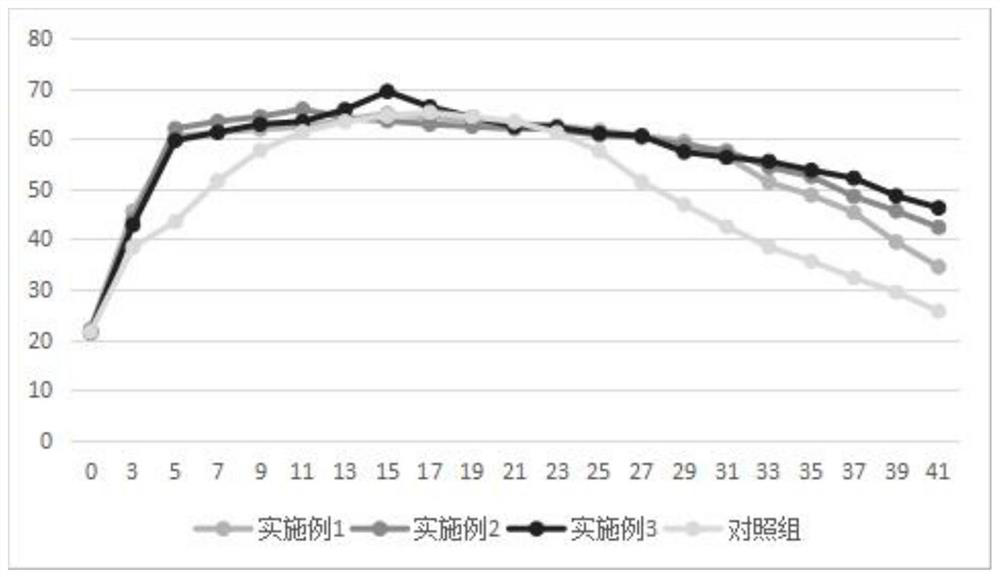

Embodiment 1

[0032] Embodiment 1, the preparation one of compound fermentation bacterial agent

[0033]S1: streak Bacillus stearothermophilus on nutrient agar medium, culture at 60°C for 2 days, streak inoculation activation and culture 5 times to form a single colony, and then inoculate a single colony on beef extract, peptone and On the liquid medium formed by sodium chloride, the activated Bacillus stearothermophilus is obtained, the activated Bacillus stearothermophilus is inoculated on the fermentation medium, and the thermophilic fat is obtained by culturing in a water bath for 30H under the condition of 58°C Bacillus subtilis fermented bacteria liquid, for standby use; streak inoculated Bacillus subtilis on nutrient agar medium, cultivate at 32°C for 3 days, streak inoculation, activate and cultivate 5 times to form a single colony, and then inoculate a single colony into beef On the liquid medium formed of cream, peptone, sodium chloride, glucose and water, obtain activated Bacillu...

Embodiment 2

[0038] Embodiment 2, the preparation two of compound fermentation bacterial agent

[0039] S1: Streak Bacillus stearothermophilus on nutrient agar medium, culture at 60°C for 2.5 days, streak inoculation activation and culture 5 times to form a single colony, and then inoculate a single colony on beef extract, peptone and On the liquid medium formed by sodium chloride, the activated Bacillus stearothermophilus is obtained, the activated Bacillus stearothermophilus is inoculated on the fermentation medium, and the thermophilic fat is obtained by culturing in a water bath for 27 hours under the condition of 58° C. Bacillus subtilis fermented bacteria liquid, for standby use; streak Bacillus subtilis on nutrient agar medium, culture at 32°C for 4 days, streak inoculation activation and culture 5 times to form a single colony, and then inoculate a single colony into beef On the liquid medium formed of cream, peptone, sodium chloride, glucose and water, obtain activated Bacillus su...

Embodiment 3

[0044] Embodiment 3, the preparation two of compound fermentation bacterial agent

[0045] S1: Streak inoculation of Bacillus stearothermophilus on nutrient agar medium, culture at 60°C for 3 days, streak inoculation, activate and cultivate 5 times to form a single colony, and then inoculate a single colony on beef extract, peptone and On the liquid medium formed by sodium chloride, the activated Bacillus stearothermophilus is obtained, the activated Bacillus stearothermophilus is inoculated on the fermentation medium, and the thermophilic fat is obtained by culturing in a water bath for 24 hours under the condition of 58° C. Bacillus subtilis fermented bacteria liquid, for standby use; streak Bacillus subtilis on nutrient agar medium, cultivate at 32°C for 5 days, streak inoculation, activate and cultivate 5 times to form a single colony, and then inoculate a single colony into beef On the liquid medium formed by cream, peptone, sodium chloride, glucose and water, obtain acti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com