Multi-feature thin plate part quality prediction and process parameter optimization based on machine learning

A technology for process parameter optimization and process parameter application in the direction of instruments, simulators, computer control, etc., can solve the problems of cumbersome formula solution, low precision, cumbersome expression, etc., to improve self-adaptive ability, improve processing quality, reliable high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

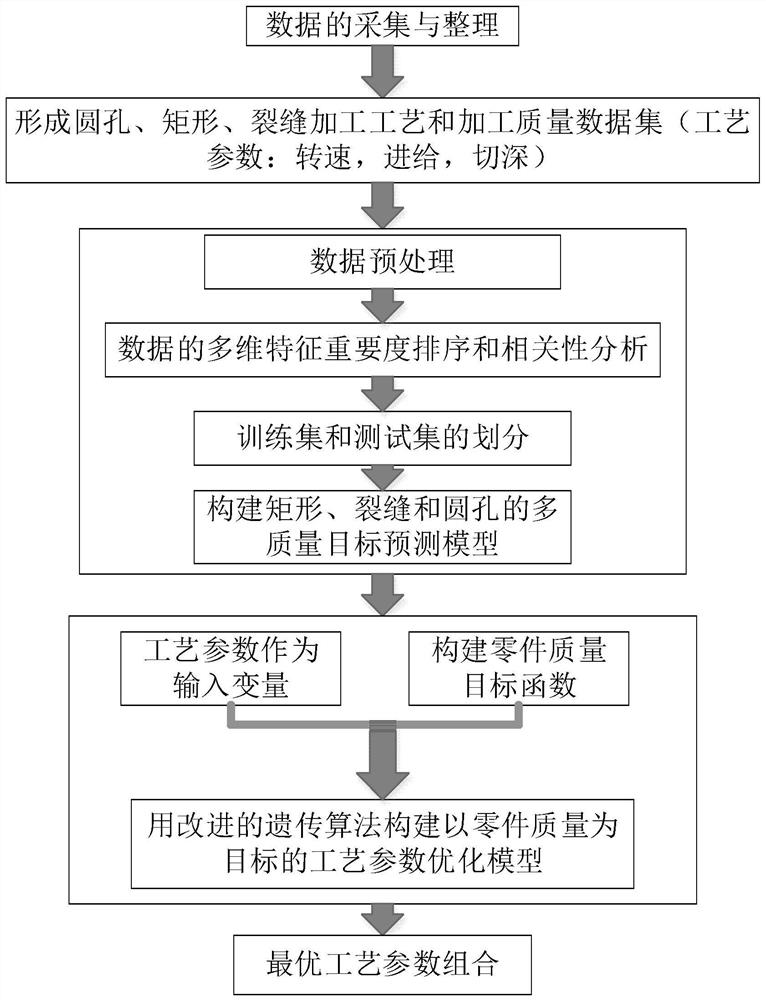

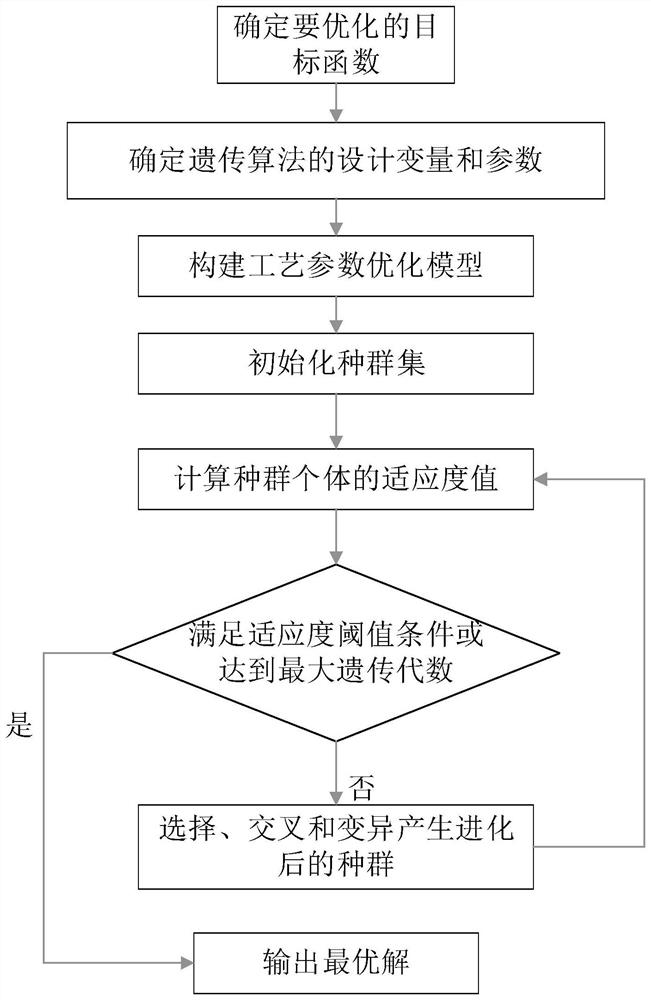

Embodiment 1

[0027]In the existing CNC machining, it is difficult to predict the quality of workpieces processed by CNC machine tools, and the setting of process parameters of CNC machine tools often depends on traditional experience. The flat plate slot antenna is a typical thin plate part. As a key equipment for communication, broadcasting, radar, guidance, early warning, anti-radar and missile antenna, it has high radiation efficiency, high power, light structure, small thickness, light weight, etc. Excellent electrical performance, especially suitable for airborne equipment that requires light weight and small size. The processing accuracy of the flat-panel slot antenna is extremely high, and the processing process is complicated. If only relying on traditional experience to guide the processing process, the processing accuracy will not be high. , the unstable abnormal phenomenon in the processing process seriously affects the processing quality and causes waste of materials; the presen...

Embodiment 2

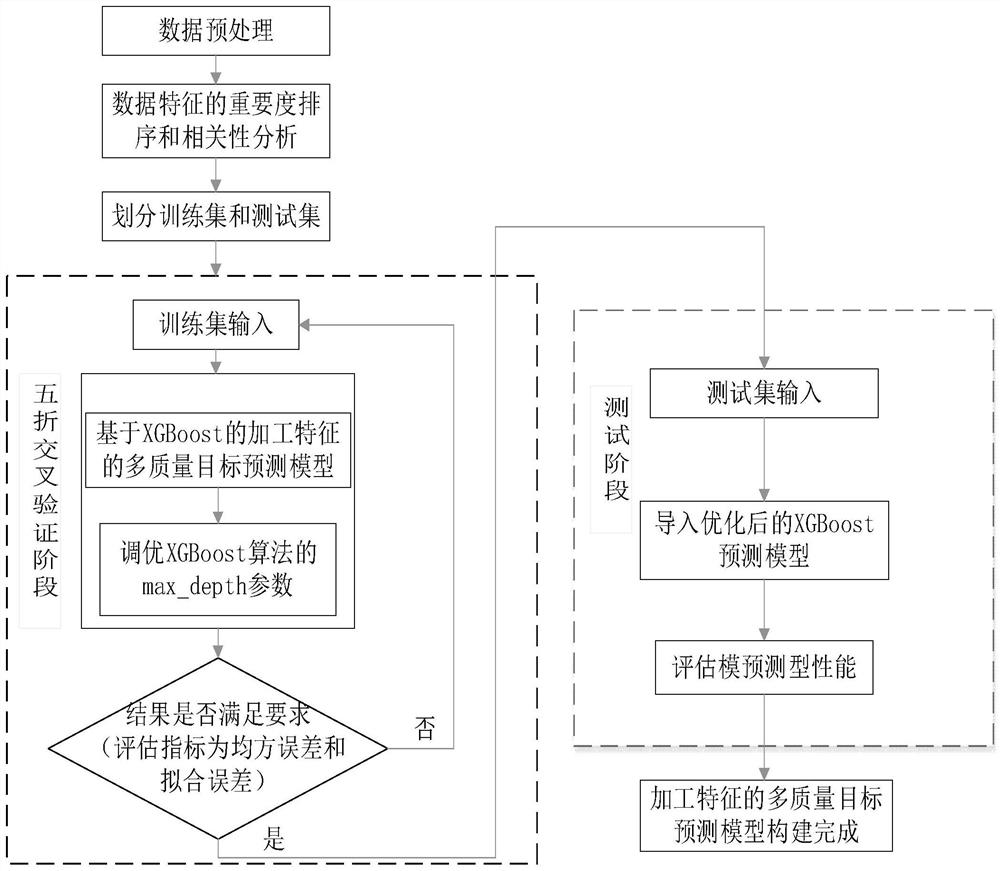

[0038] The multi-quality target prediction and process parameter optimization recommendation method for NC machining of multi-processing feature thin plate parts is the same as in Example 1, the collection and processing process and processing quality data set described in step (1), which collects and organizes processing technology and processing The process of quality datasets consists of the following steps:

[0039] (1.1) Collection data set: The tool parameter information of the CNC machine tool is an end mill, with a diameter of 1 and a clamping length of 17; the processing features are: rectangle, crack and round hole; the process parameters are: speed, depth of cut and feed, CNC The machine tool performs milling in the order of rectangles, cracks and round holes, collects the process parameter data of the flat cracked antenna through the MDC module of the CNC machine tool, and collects the processing characteristics of the flat cracked antenna through the three-coordina...

Embodiment 3

[0043] The multi-quality target prediction and process parameter optimization recommendation method for multi-processing characteristic thin-plate parts NC machining is the same as that of embodiment 1-2, and the data preprocessing is performed by replacing the abnormal value with the average value described in step (2), and the data preprocessing process includes The following steps:

[0044](2.1) Statistical calculation of the data set: statistical calculation of the processing technology data of the rectangle, crack and round hole of the flat plate cracked antenna, including the lower quartile, median, upper quartile, and quartile spacing.

[0045] (2.2) Judgment of abnormal value of the data set: According to the following formula, the abnormal value judgment is performed on the processing feature rectangle, crack and round hole data of the processed part:

[0046] value>QU+1.5IQR or value

[0047] Among them, value represents the abnormal value in each process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com