Colloidal imprinted carbon CICs with adjustable pore throat size as well as synthesis method and application of colloidal imprinted carbon CICs

A synthesis method, CIC-X-Y technology, applied in the field of new porous carbon materials, to achieve good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

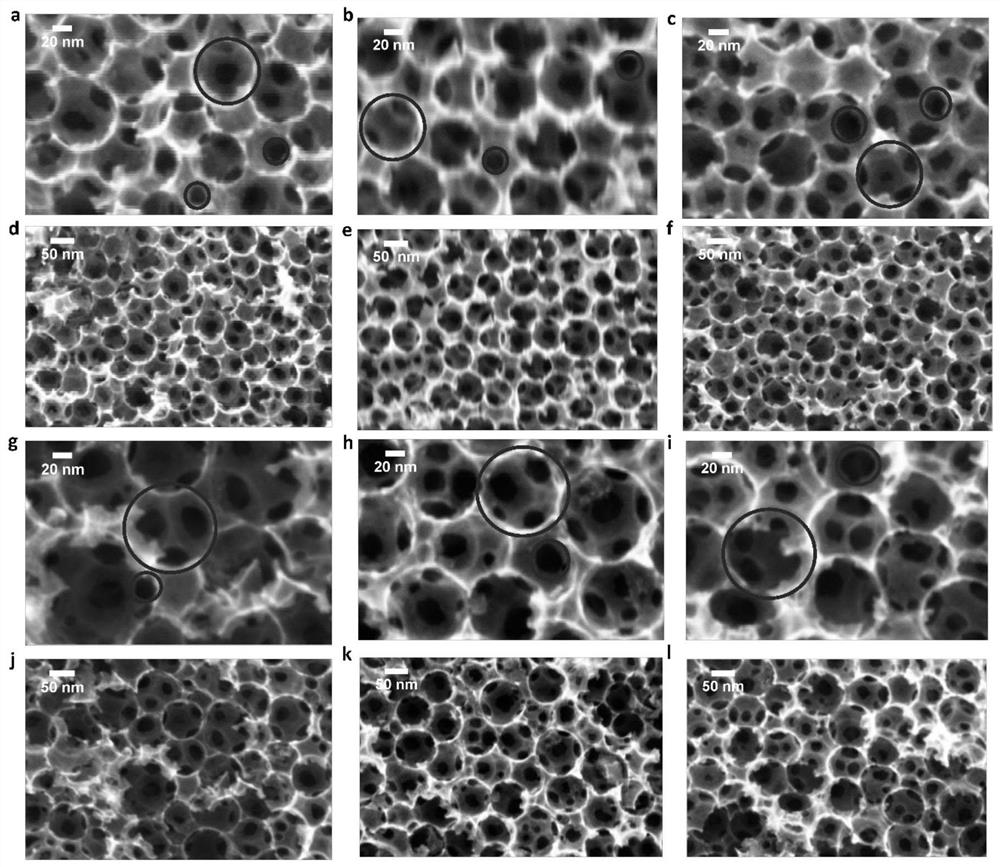

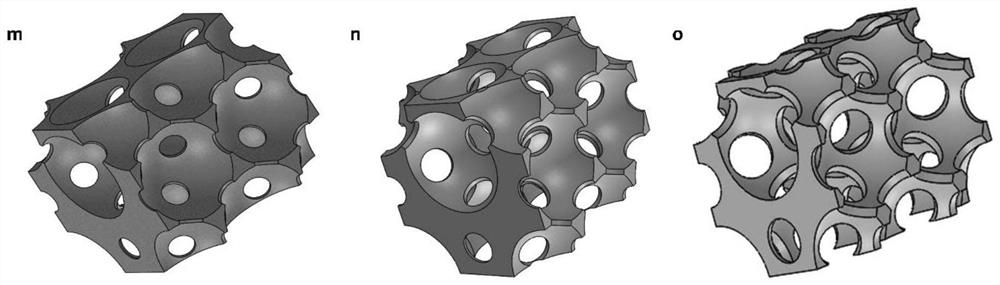

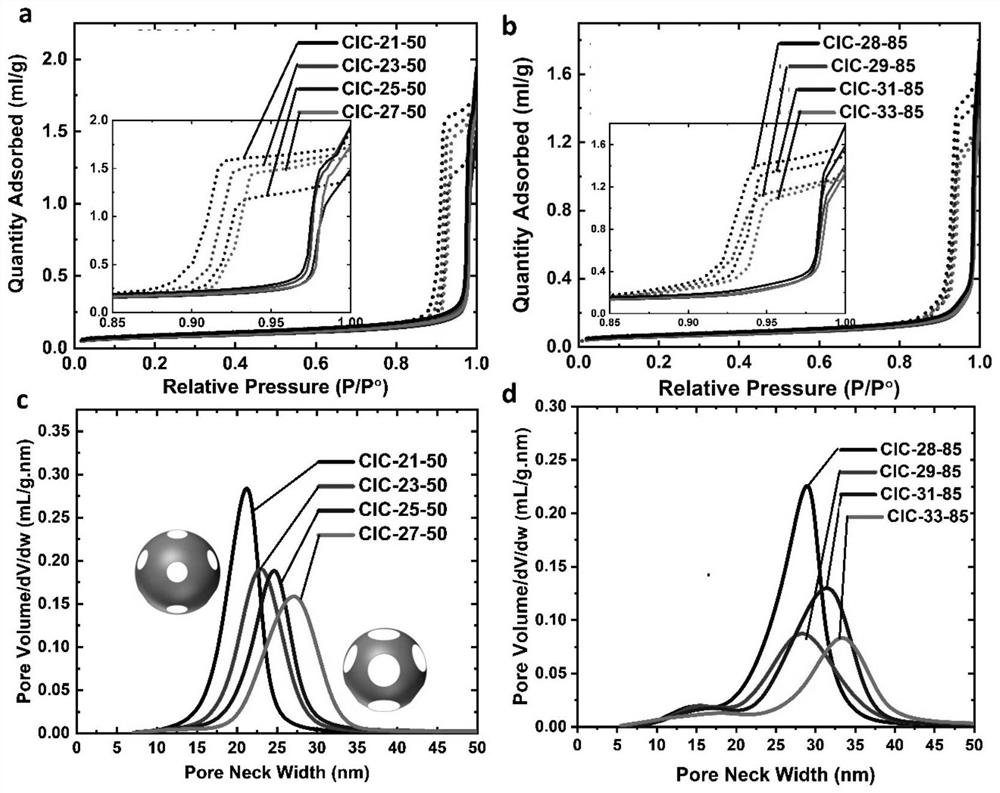

Image

Examples

Embodiment 1

[0041] The specific technological process of the present embodiment is as follows:

[0042] S1, drying and grinding the silica sol with a particle size of 50nm to obtain silicon powder, and continuing to dry;

[0043] S2, adding the ethanol solution to the dry silica powder, stirring evenly to obtain the first mixture;

[0044] S3, drying the first mixture at 50° C., exposing it to air for a period of time after cooling, using water vapor in the air to hydrolyze TEOS, and then drying again to obtain silicon powder;

[0045] S4, mixing the dried silicon powder with the carbon precursor (mesophase pitch MP) to obtain a second mixture;

[0046] S5. Under a protective nitrogen atmosphere, heat-treat the second mixture at 300°C for 2 hours, cool to room temperature, and then gradually raise the temperature to 800°C for carbonization treatment for 4 hours, with a heating rate of 5°C / min;

[0047] S6, the solid product was refluxed in 3M NaOH solution for 24h to remove SiO 2 Templ...

Embodiment 2

[0050] The specific technological process of the present embodiment is as follows:

[0051]S1, drying and grinding the silica sol with a particle size of 50nm to obtain silicon powder, and continuing to dry;

[0052] S2. Add the ethanol dispersion solution of ethyl orthosilicate to the dry silica powder, and stir evenly to obtain the first mixture, wherein the mass concentration of ethyl orthosilicate is 4.96wt.%.

[0053] S3, drying the first mixture at 80° C., exposing it to air for a period of time after cooling, using water vapor in the air to hydrolyze TEOS, and then drying again to obtain silicon powder;

[0054] S4, mixing the dried silicon powder with the carbon precursor (mesophase pitch MP) to obtain a second mixture;

[0055] S5. Under the protective atmosphere of nitrogen, heat-treat the second mixture at 400°C for 2 hours, cool to room temperature, and then gradually raise the temperature to 900°C for carbonization treatment for 2 hours, with a heating rate of 5°...

Embodiment 3

[0059] The specific technological process of the present embodiment is as follows:

[0060] S1, drying and grinding the silica sol with a particle size of 50nm to obtain silicon powder, and continuing to dry;

[0061] S2. Add the ethanol dispersion solution of ethyl orthosilicate to the dry silica powder, and stir evenly to obtain the first mixture, wherein the mass concentration of ethyl orthosilicate is 8.67wt.%.

[0062] S3, drying the first mixture at 60° C., exposing it to air for a period of time after cooling, using water vapor in the air to hydrolyze TEOS, and then drying again to obtain silicon powder;

[0063] S4, mixing the dried silicon powder with the carbon precursor (mesophase pitch MP) to obtain a second mixture;

[0064] S5. Under a protective nitrogen atmosphere, heat the second mixture at 500°C for 5 hours, cool to room temperature, and then gradually heat up to 1200°C for carbonization treatment for 3 hours, with a heating rate of 5°C / min;

[0065] S6, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com