Anti-overcharge rate type positive pole piece, manufacturing method thereof and lithium ion battery based on anti-overcharge rate type positive pole piece

A technology for lithium-ion batteries and positive pole pieces, which is applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as delithiation of positive electrode materials, and achieve the effects of improving conductivity, improving battery rate performance, and improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

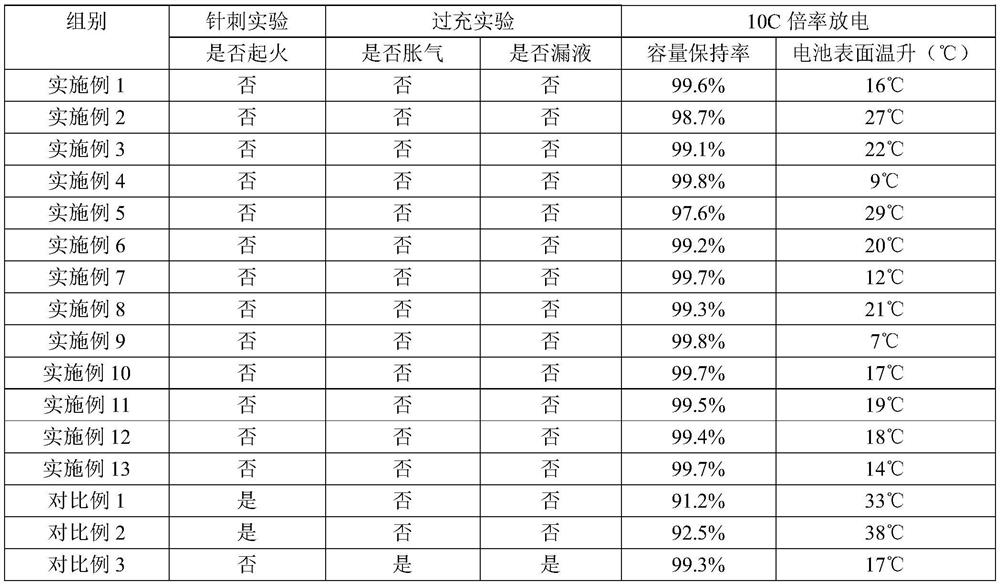

Examples

Embodiment 1

[0060] With N-methylpyrrolidone as solvent, CNT, nano-Ti 4 o 7 , nano-AlN, DDB, dispersant (the composite mass ratio of titanate coupling agent and PVP in the dispersant is 2:3) and the mass percentages are 1%, 1%, 2%, 0.5%, and 0.5% respectively. Compound Additive Slurry. Wherein, CNT is a mixture of multi-walled carbon nanotubes and single-walled carbon nanotubes in equal mass ratios. The specific configuration process is as follows: first dissolve the dispersant completely in N-methylpyrrolidone solvent, then add CNT, nano Ti 4 o 7 , nano-AlN, DDB powder, ultrasonic 10min until the powder is evenly dispersed, and the composite additive slurry is obtained.

[0061] A double planetary mixer is used to add positive electrode active materials, conductive agents, binders, and solvents, and the positive electrode slurry is prepared according to the conventional lithium ion battery homogenization method. The positive electrode active material is lithium iron phosphate, the co...

Embodiment 2

[0066] With N-methylpyrrolidone as solvent, CNT, nano-Ti 4 o 7 , nano-AlN, DDB, dispersant (the composite mass ratio of titanate coupling agent and PVP in the dispersant is 2:3) and the mass percentages are 1%, 1%, 2%, 0.5%, and 0.5% respectively. Compound Additive Slurry. Among them, CNT is a multi-walled carbon nanotube. The specific configuration process is as follows: first dissolve the dispersant completely in N-methylpyrrolidone solvent, then add CNT, nano Ti 4 o 7 , nano-AlN, DDB powder, ultrasonic 240min until the powder is uniformly dispersed, and a composite dispersant slurry is obtained.

[0067] A double planetary mixer is used to add positive electrode active materials, conductive agents, binders, and solvents, and the positive electrode slurry is prepared according to the conventional lithium ion battery homogenization method. The positive electrode active material is lithium iron phosphate, the conductive agent is conductive carbon black, and the binder is ...

Embodiment 3

[0071] With N-methylpyrrolidone as solvent, CNT, nano-Ti 4 o 7, nano-AlN, DDB, dispersant (the composite mass ratio of titanate coupling agent and PVP in the dispersant is 3:2) and the mass percentages are 1%, 1%, 2%, 0.5%, and 0.5% respectively. Compound Additive Slurry. Among them, CNT is a single-walled carbon nanotube. The specific configuration process is as follows: first dissolve the dispersant completely in N-methylpyrrolidone solvent, then add CNT, nano Ti 4 o 7 , nano-AlN, DDB powder, ultrasonic 30min until the powder is uniformly dispersed, and the composite additive slurry is obtained.

[0072] By spraying, the above-mentioned composite additive slurry is evenly sprayed onto the surface of the positive electrode current collector. The mass percentage of the composite additive per unit area and the positive electrode active material per unit area is 2.36%. The positive current collector is selected from carbon-coated aluminum foil. Dry and set aside.

[0073...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com