Preparation method of zanthoxylum armatum oil microcapsule and preparation method of zanthoxylum armatum gourmet powder

A technology of rattan pepper oil and microcapsules, which is applied in the field of preparation of vegetable oil condiments, can solve the problems of no further improvement in the development and utilization of rattan pepper oil, affect the quality of rattan pepper oil products, and narrow application range, and achieve large-scale production And application, embedding effect is good, product quality is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

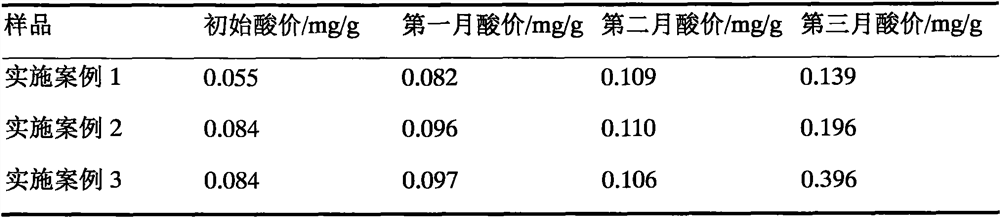

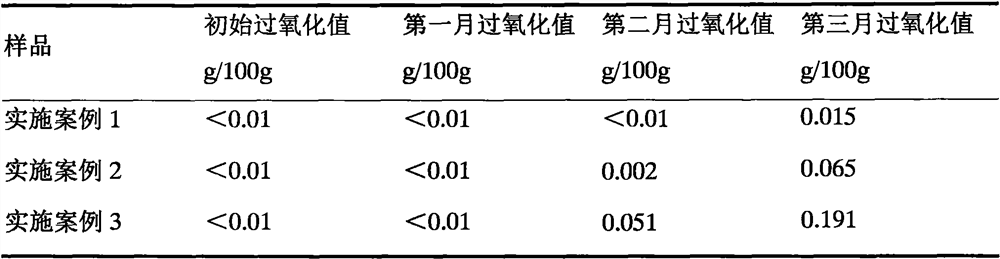

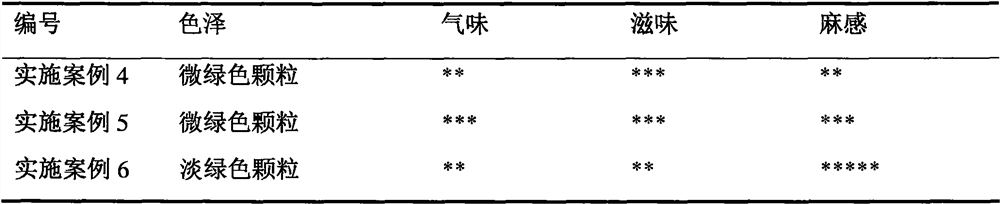

Examples

example 1

[0032] Example 1, a preparation method of rattan pepper oil microcapsules, comprising the following steps:

[0033] (1) Prepare wall material solution: prepare wall material solution by mixing β-cyclodextrin, chitosan, modified starch, and maltodextrin with water according to mass percentage, wherein 10% of β-cyclodextrin, chitosan 0.5%, 25% modified starch, and 64.5% maltodextrin to form a wall material solution with a solid content of 20%, and heat to 90°C to completely dissolve and mix the wall material;

[0034](2) Emulsification: mix the above-mentioned wall material solution with rattan pepper oil of 20 degrees, stir at a high speed until the mixture is uniform, and emulsify to obtain an emulsion, wherein the solids of the wall material solution and rattan pepper oil are added at a ratio of 3:1;

[0035] (3) high-pressure homogenization: the above-mentioned emulsion is homogenized 2 times at 30MPa under a high-pressure homogenizer, and then 1 time with a pressure of 45MP...

example 2

[0038] Example 2, a preparation method of rattan pepper oil microcapsules, comprising the following steps:

[0039] (1) Prepare wall material solution: prepare wall material solution by mixing β-cyclodextrin, chitosan, modified starch, and maltodextrin with water according to mass percentage, wherein β-cyclodextrin 12%, chitosan 1%, 33% modified starch, and 54% maltodextrin to form a wall material solution with a solid content of 18%, and heat to 95°C to completely dissolve and mix the wall material;

[0040] (2) Emulsification: Mix the above-mentioned wall material solution with rattan pepper oil of 20 degrees, stir at a high speed until the mixture is uniform, and emulsify to obtain an emulsion, wherein, the solid content of the wall material solution and rattan pepper oil are added at a ratio of 1.5:1;

[0041] (3) high-pressure homogenization: the above-mentioned emulsion is homogenized 2 times at 35MPa under a high-pressure homogenizer, and then homogenized 2 times at a p...

example 3

[0044] Example 3, a preparation method of rattan pepper oil microcapsules, comprising the following steps:

[0045] (1) Prepare wall material solution: prepare wall material solution by mixing β-cyclodextrin, chitosan, modified starch, and maltodextrin with water according to mass percentage, wherein 6% of β-cyclodextrin, chitosan 0.1%, 30% modified starch, and 63.9% maltodextrin to form a wall material solution with a solid content of 20%, and heat to 90°C to completely dissolve and mix the wall material;

[0046] (2) Emulsification: mix the above-mentioned wall material solution with rattan pepper oil of 120 degrees, stir at a high speed until the mixture is uniform, and emulsify to obtain an emulsion, wherein the solids of the wall material solution and rattan pepper oil are added at a ratio of 2:1;

[0047] (3) high-pressure homogenization: the above-mentioned emulsion is homogenized 2 times at 30MPa under a high-pressure homogenizer, and then 1 time with a pressure of 40M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com