Full-biodegradable high-strength polylactic acid-based injection molding special material and preparation method thereof

A polylactic acid-based, high-strength technology, applied in the field of degradable polymer materials, can solve the problems of consumption, low energy consumption, and low equipment dependence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

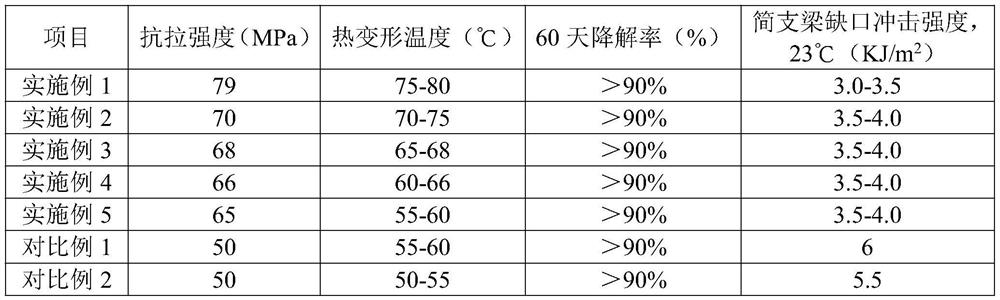

Examples

preparation example Construction

[0020] Another object of the present invention is to provide a preparation method of the fully biodegradable high-strength polylactic acid-based injection molding special material, characterized in that it includes the following steps: mixing the raw materials uniformly by weight to obtain a mixed material, and then The mixed material is added into a twin-screw base material machine for melt blending, extrusion, cooling and granulation in sequence to obtain a fully biodegradable high-strength polylactic acid-based special material for injection molding.

[0021] Preferably, the temperature of the barrel of the twin-screw extruder is 160-180°C, and the temperature of the die head is 170°C.

[0022] Preferably, the screw speed of the twin-screw extruder is 400-600 rpm, and the screw length-diameter ratio L / D is 52:1.

[0023] Due to the application of the above technical solutions, the present invention has the following advantages compared with the prior art: the present invent...

Embodiment 1

[0026] This example provides a fully biodegradable high-strength polylactic acid-based special injection molding material, which is characterized in that it is made from the following raw materials in parts by weight: 5 parts of carbon dioxide-based PPC, 60 parts of PLA, 20 parts of PBAT, and a dispersant. 0.2 part, ADR44680.1 part, 0.1 part of lubricant, 3 parts of filler.

[0027] The filler is ultrafine talc; the particle size of the filler is 5000 mesh; the lubricant is a mixture of erucamide and stearic acid amide in a mass ratio of 1:1; the dispersant is ethylene Distearic acid amide.

[0028] Another object of the present invention is to provide a preparation method of the fully biodegradable high-strength polylactic acid-based injection molding special material, characterized in that it includes the following steps: mixing the raw materials uniformly by weight to obtain a mixed material, and then The mixed material is added to a twin-screw base material machine for me...

Embodiment 2

[0031] This example provides a fully biodegradable high-strength polylactic acid-based special material for injection molding. Its formula and preparation method are basically the same as those in Example 1. The difference is that it is made from the following raw materials in parts by weight: carbon dioxide-based PPC 6 parts, PLA 63 parts, PBAT 22 parts, dispersant 0.22 parts, ADR4468 0.15 parts, lubricant 0.15 parts, filler 3.5 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com