Extinction nylon composite material and preparation method thereof

A nylon composite material and composite material technology are applied in the field of matting nylon composite materials and their preparation, which can solve the problems of inability to meet the matting requirements of materials and limited matting ability, and achieve good matting performance, reducing transparency, and significant effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

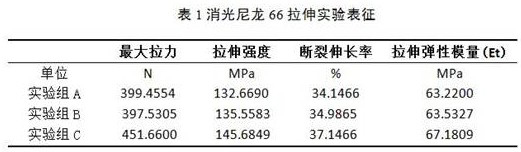

Examples

Embodiment 1

[0025] A matting nylon composite material, according to parts by weight, the raw materials of the composite material include 75 parts of nylon 66, 7 parts of EPDM, 0.7 part of rutile, 11 parts of functional masterbatch, 0.1 part of main antioxidant, 0.1 part of auxiliary antioxidant , 0.4 parts lubricant, 0.4 parts flow agent and 0.5 parts nylon nucleating agent.

[0026] In this embodiment, according to parts by weight, the functional masterbatch is composed of 19 parts of silicon dioxide, 9 parts of calcium oxide, 9 parts of magnesium oxide, 14 parts of ferric oxide, 0.8 part of nylon 6 and 0.9 part of silane coupling Prepared after mixing the ingredients in proportion.

[0027] In this embodiment, the preparation method of the functional masterbatch is as follows: according to the proportion, first put nylon 6 and silane coupling agent into the high mixer and mix them for 5 minutes, and then put the remaining powder into the high mixer respectively. Continue to mix several...

Embodiment 2

[0037] A kind of extinction nylon composite material, according to weight parts, the raw material of this composite material comprises 80 parts of nylon 66, 9 parts of EPDM, 0.9 part of rutile, 13 parts of functional masterbatch, 0.3 part of main antioxidant, 0.3 part of auxiliary antioxidant , 0.6 parts lubricant, 0.6 parts flow agent and 0.7 parts nylon nucleating agent.

[0038] In this embodiment, according to parts by weight, the functional masterbatch is composed of 21 parts of silicon dioxide, 11 parts of calcium oxide, 11 parts of magnesium oxide, 16 parts of ferric oxide, 1.2 parts of nylon 6 and 1.1 parts of silane coupling Prepared after mixing the ingredients in proportion.

[0039] In this embodiment, the preparation method of the functional masterbatch is the same as that in Embodiment 1.

[0040] In this example, the primary antioxidant is BASF 1098, and the secondary antioxidant is BASF 168.

[0041] In this embodiment, the lubricant is silicone powder.

[0...

Embodiment 3

[0048] A kind of extinction nylon composite material, according to weight parts, the raw material of this composite material comprises 77 parts of nylon 66, 8 parts of EPDM, 0.8 part of rutile, 12 parts of functional masterbatch, 0.2 part of main antioxidant, 0.2 part of auxiliary antioxidant , 0.5 parts lubricant, 0.5 parts flow agent and 0.6 parts nylon nucleating agent.

[0049]In this embodiment, according to parts by weight, the functional masterbatch is composed of 20 parts of silicon dioxide, 10 parts of calcium oxide, 10 parts of magnesium oxide, 15 parts of ferric oxide, 1 part of nylon 6 and 1 part of silane coupling Prepared after mixing the ingredients in proportion.

[0050] In this embodiment, the preparation method of the functional masterbatch is the same as the above embodiment.

[0051] Preferably, the primary antioxidant is BASF 1098, and the secondary antioxidant is BASF 168.

[0052] Preferably, the lubricant is silicone powder.

[0053] A kind of prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com