Nano oxide and carbide dispersion strengthened low-activation steel as well as preparation method and application thereof

A technology of nano-oxide and low-activation steel, which is applied in the field of metal material processing, and can solve the problems of difficulty in preparing large and complex components, high efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

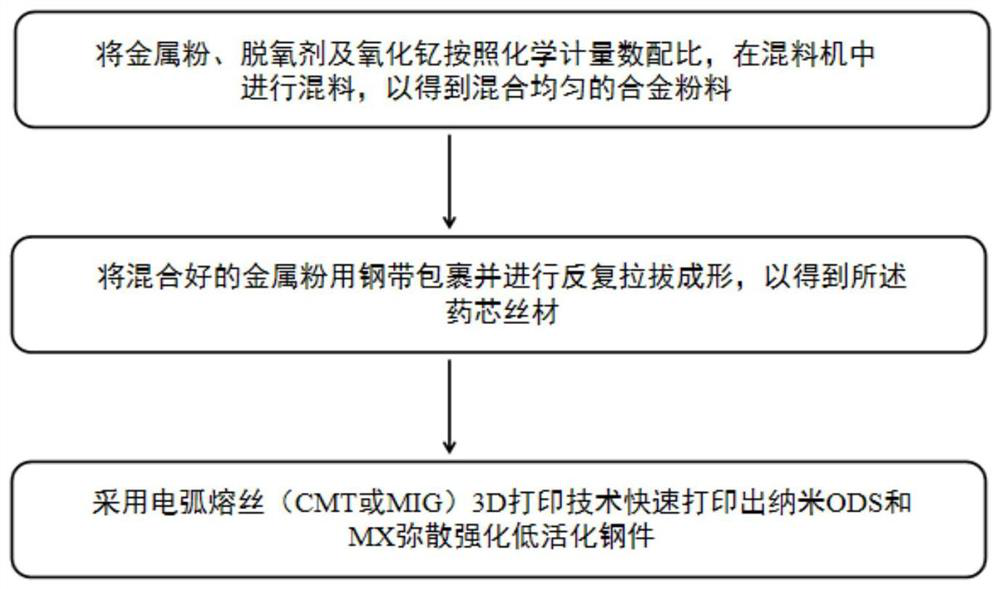

[0033] A preparation method for dispersion strengthened low activation steel, such as figure 1 shown, including the following steps:

[0034] Step 1, mechanically stirring the alloy steel powder and the nanometer oxide powder in a mixer to obtain a mixed powder. Specifically, alloy steel powder is composed of (WFe75% 200g, Cr 900g, TiFe30% 66.7g, SiFe75% 17.8g, MnFe75% 71.1g, Fe281.9g) and nano-diyttrium trioxide 37.5g are mixed under mechanical stirring , to obtain a mixed powder. Wherein, the stirring time is 5 hours; the alloy steel powder is stainless steel powder or other special-purpose alloy steel powder, the average particle size is less than 100 μm, and the wire drawing formability is good; Stable Rare Earth Y 2 o3 , the average particle size is less than 40nm; the mass of oxide powder in the mixed powder accounts for 0.5% of the total content.

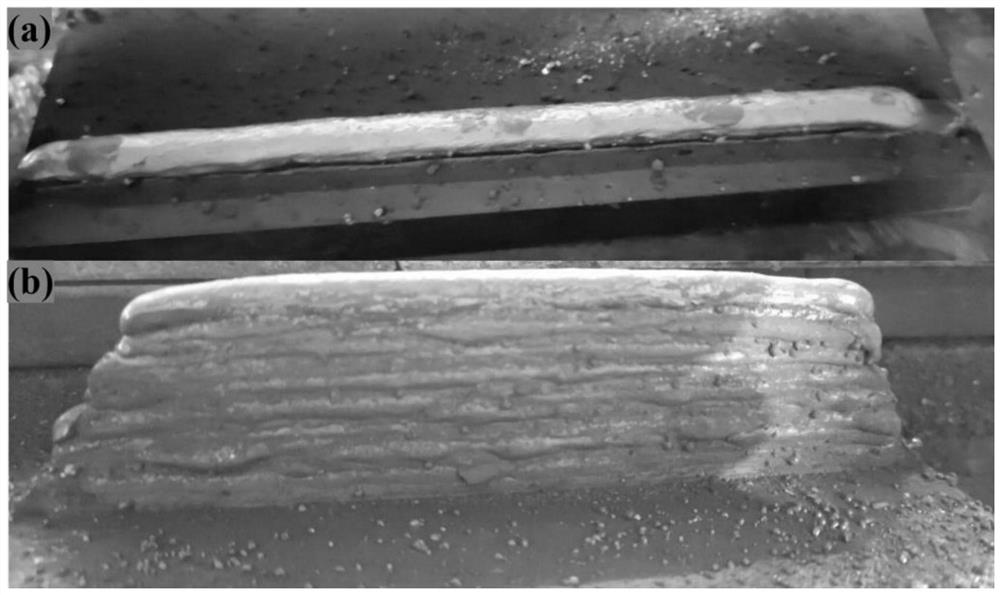

[0035] Step 2, wrapping the mixed powder with a steel strip, and forming a flux-cored welding wire through wire drawing...

Embodiment 2

[0042] The main difference between this example and Example 1 is that the composition of the composite metal powder is different, and its main chemical composition and mass percentage are shown in Table 2.

[0043] Table 2 embodiment 2 composite metal powder composition (wt %)

[0044] C Cr W mn Ti Si Y 2 o 3

Embodiment 3

[0046] The main difference between this example and Example 1 is that the composition of the composite metal powder is different, and its main chemical composition and mass percentage are shown in Table 3.

[0047] Table 3 embodiment 3 composite metal powder composition (wt %)

[0048] C Cr W mn Ti Si Y 2 o 3

Fe 0.064 9.0 1.5 0.8 0.5 0.2 0.2 margin

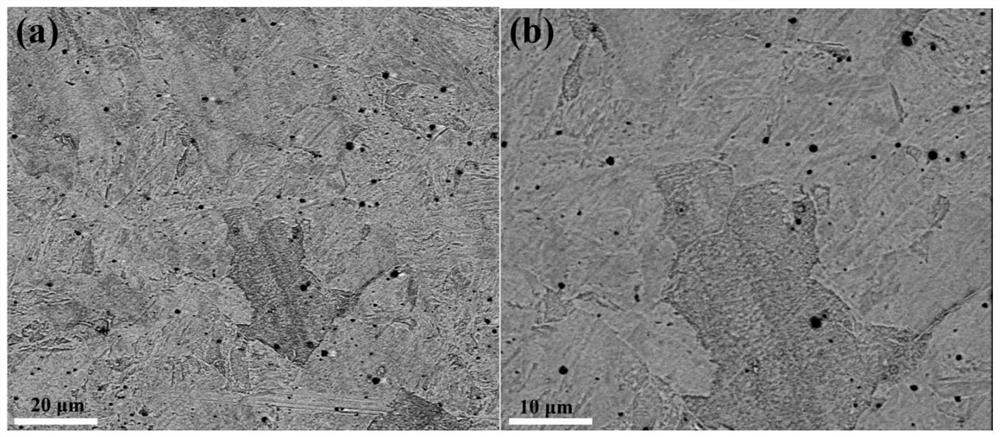

[0049] image 3 It is the SEM figure of the dispersion strengthened low activation steel material prepared by embodiment 1, wherein image 3 (a) is the SEM image under low power microscope and image 3 (b) is the SEM picture of the SEM photo under high magnification;

[0050] Depend on image 3 It can be seen that for the nano-ODS and MX strengthened low-activation steel piece prepared in Example 1 of the present application, there are fine oxides and MX precipitated inside the alloy structure at room temperature.

[0051] Figure 4 is the STEM figure of the dispersion strengthened ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com