A nano-oxide dispersion strengthened steel part and its rapid additive manufacturing method

A nano-oxide and dispersion strengthening technology, applied in the field of additive manufacturing, can solve the problems that limit the actual production and application of ODS steel, and achieve the effects of inhibiting aggregation and growth, rapid cooling and solidification, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

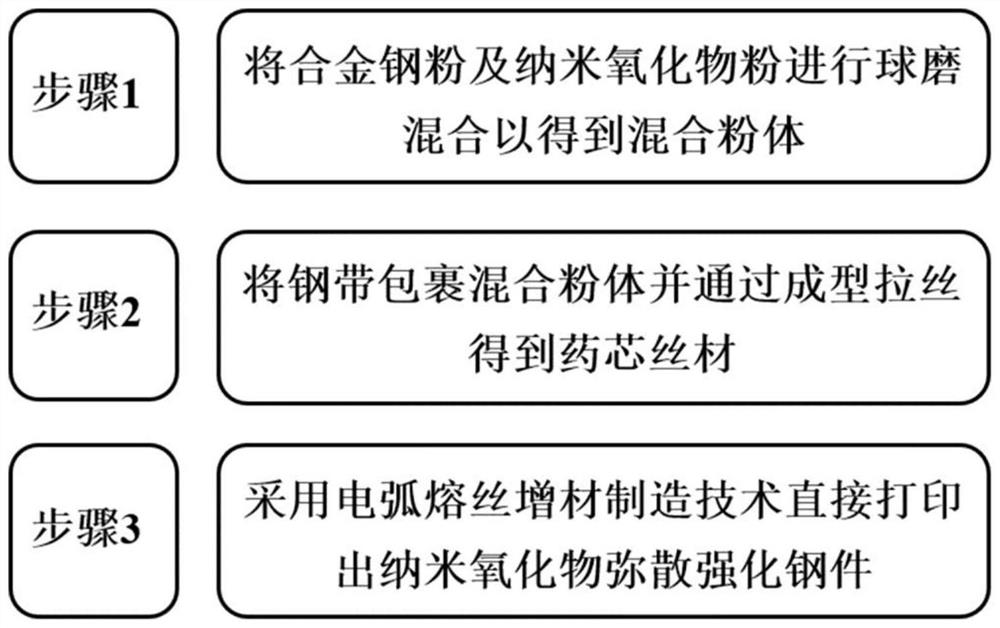

[0042] The rapid additive manufacturing method for nano-oxide dispersion strengthened steel provided in Example 1 of the present invention mainly includes the following steps:

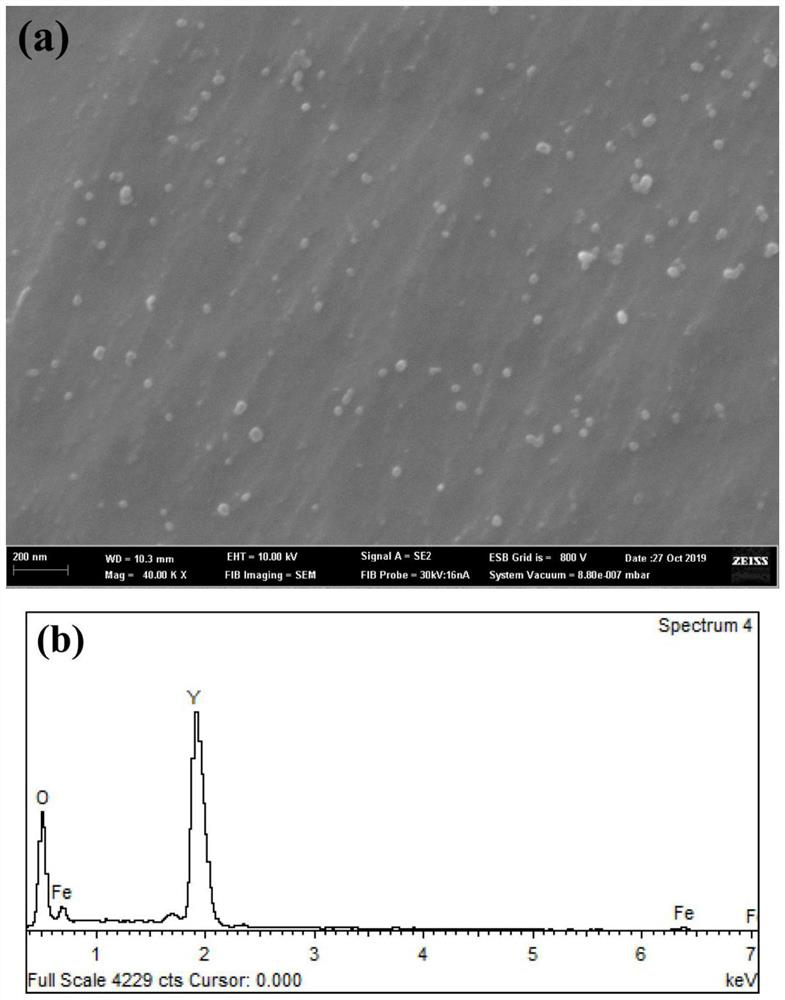

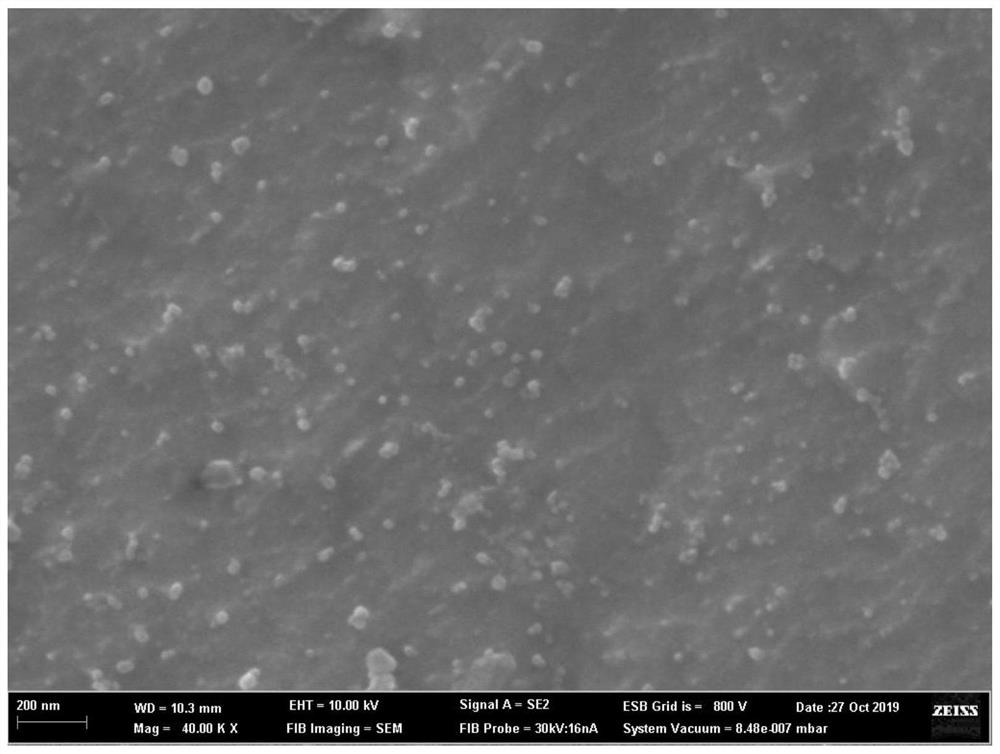

[0043] First, with 316 stainless steel powder and nano Y 2 o 3 Powder is the raw material, where Y 2 o 3 The blending amount is 1wt%, and 1wt% stearic acid is added as a process control agent at the same time, all of which are added into a stainless steel ball mill jar, evacuated to a vacuum, and ball milled on a planetary ball mill for 1 hour to obtain a mixed powder. Then, after the mixed powder is wrapped with a steel belt by a molding machine, it is then reduced in diameter by a multi-channel die of a wire drawing machine to obtain a metal cored wire with a diameter of 1.5 mm, wherein the powder filling rate is 10%. Finally, put the obtained flux-cored wire into the arc fuse device, set the operating current to 150A, the operating voltage to 20V, the moving speed of the welding torch to 5mm / s, a...

Embodiment 2

[0046] The rapid additive manufacturing method for nano-oxide dispersion strengthened steel provided in Embodiment 2 of the present invention mainly includes the following steps:

[0047] First, with 316 stainless steel powder and nano Y 2 o 3 Powder is the raw material, where Y 2 o 3 The blending amount is 5wt%, and 10wt% stearic acid is added as a process control agent at the same time, all the above raw materials are added into a stainless steel ball mill tank, evacuated to a vacuum, and ball milled on a planetary ball mill for 5 hours to obtain a mixed powder. Then, the mixed powder is wrapped with a steel belt by a molding machine, and then passed through a multi-channel die of a wire drawing machine to reduce the diameter to obtain a metal core wire with a diameter of 1 mm, wherein the powder filling rate is 15%. Finally, put the obtained flux-cored wire into the arc fuse device, set the operating current to 150A, the operating voltage to 25V, the moving speed of the ...

Embodiment 3

[0050] The method for rapid additive manufacturing of nano-oxide dispersion strengthened steel provided in Embodiment 3 of the present invention mainly includes the following steps:

[0051] First, with 316 stainless steel powder and nano Y 2 o 3 Powder is the raw material, where Y 2 o 3 The blending amount is 5wt%, and 5wt% stearic acid is added as a process control agent at the same time, all the above raw materials are added into a stainless steel ball mill tank, evacuated to a vacuum, and ball milled and mixed on a planetary ball mill for 10 hours to obtain a mixed powder. Then the mixed powder is wrapped with a steel belt by a molding machine, and then passed through a multi-channel die of a wire drawing machine to reduce the diameter to obtain a metal core wire with a diameter of 2 mm, wherein the powder filling rate is 20%. Finally, put the obtained flux-cored wire into the arc fuse device, set the operating current to 200A, the operating voltage to 20V, the moving s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com